BMW 2004 Annual Report Download - page 165

Download and view the complete annual report

Please find page 165 of the 2004 BMW annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.-

1

1 -

2

2 -

3

3 -

4

4 -

5

5 -

6

6 -

7

7 -

8

8 -

9

9 -

10

10 -

11

11 -

12

12 -

13

13 -

14

14 -

15

15 -

16

16 -

17

17 -

18

18 -

19

19 -

20

20 -

21

21 -

22

22 -

23

23 -

24

24 -

25

25 -

26

26 -

27

27 -

28

28 -

29

29 -

30

30 -

31

31 -

32

32 -

33

33 -

34

34 -

35

35 -

36

36 -

37

37 -

38

38 -

39

39 -

40

40 -

41

41 -

42

42 -

43

43 -

44

44 -

45

45 -

46

46 -

47

47 -

48

48 -

49

49 -

50

50 -

51

51 -

52

52 -

53

53 -

54

54 -

55

55 -

56

56 -

57

57 -

58

58 -

59

59 -

60

60 -

61

61 -

62

62 -

63

63 -

64

64 -

65

65 -

66

66 -

67

67 -

68

68 -

69

69 -

70

70 -

71

71 -

72

72 -

73

73 -

74

74 -

75

75 -

76

76 -

77

77 -

78

78 -

79

79 -

80

80 -

81

81 -

82

82 -

83

83 -

84

84 -

85

85 -

86

86 -

87

87 -

88

88 -

89

89 -

90

90 -

91

91 -

92

92 -

93

93 -

94

94 -

95

95 -

96

96 -

97

97 -

98

98 -

99

99 -

100

100 -

101

101 -

102

102 -

103

103 -

104

104 -

105

105 -

106

106 -

107

107 -

108

108 -

109

109 -

110

110 -

111

111 -

112

112 -

113

113 -

114

114 -

115

115 -

116

116 -

117

117 -

118

118 -

119

119 -

120

120 -

121

121 -

122

122 -

123

123 -

124

124 -

125

125 -

126

126 -

127

127 -

128

128 -

129

129 -

130

130 -

131

131 -

132

132 -

133

133 -

134

134 -

135

135 -

136

136 -

137

137 -

138

138 -

139

139 -

140

140 -

141

141 -

142

142 -

143

143 -

144

144 -

145

145 -

146

146 -

147

147 -

148

148 -

149

149 -

150

150 -

151

151 -

152

152 -

153

153 -

154

154 -

155

155 -

156

156 -

157

157 -

158

158 -

159

159 -

160

160 -

161

161 -

162

162 -

163

163 -

164

164 -

165

165 -

166

166 -

167

167 -

168

168 -

169

169 -

170

170 -

171

171 -

172

172 -

173

173 -

174

174 -

175

175 -

176

176 -

177

177 -

178

178 -

179

179 -

180

180 -

181

181 -

182

182 -

183

183 -

184

184 -

185

185 -

186

186 -

187

187 -

188

188 -

189

189 -

190

190 -

191

191 -

192

192 -

193

193 -

194

194 -

195

195 -

196

196 -

197

197 -

198

198 -

199

199 -

200

200

|

|

35

Winter 2003/2004. At the beginning of every week, dozens of buses take

employees from Leipzig to the BMW plants in Bavaria. On Friday evening they

travel back again. 1,500 Leipzig BMW employees spend time in the Munich,

Dingolfing and Regensburg plants to prepare for their tasks in Leipzig. “Training

camps” of this kind last between six and twenty-four months.

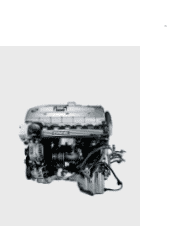

The advantage of experience: the Leipzig plant builds on all

the automotive engineering know-how accumulated by the

BMW Group over the past 75 years.

In the meantime, the first of a total of 1.6 kilometres of assembly lines are ad-

justed in the still unheated halls of the Leipzig plant. Each day suppliers trans-

port machines, robots and materials to the site. This is the most strenuous

phase for the assembly planners. Some of them were involved in developing

the BMW plant in Spartanburg, South Carolina. Put more generally, the experi-

ence that the Company has accumulated and taken stock of over the years is

integrated into the plant’s design. “Ultimately, Leipzig is the essence gained

from75 years of automotive engineering in the BMW Group”, says one of them.

The point is that the plant will not only be “state of the art” when it is opened,

but will continue to grow as the market, technologies and development of the

BMW Group require. For however permanent its outer shell may appear – it is

designed inside as an extremely lively, learning organism.

Mid-2004. Module suppliers for the BMW 3 Series move into the four supply

centres on the grounds of the Leipzig plant. What is unusual is not only that

the suppliers set up shop directly on the grounds, but that, for a limited time,

the BMW Group will let them utilise its own infrastructure. “This is a new form

of cooperation for us”, explains Peter Claussen, Plant Director. “Being so close

together means we can be up and running more quickly and cope with prob-

lems more easily. In short: the risks become more manageable for both sides.”

July 2004. The first five kestrels born on the grounds are ringed. They are to

help control the number of pigeons (and thus the pollution they cause) at the

plant. The first apples ripen on trees planted in the courtyard of the central

building.