Advance Auto Parts 2012 Annual Report Download - page 13

Download and view the complete annual report

Please find page 13 of the 2012 Advance Auto Parts annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.6

Our merchandising strategy is to carry a broad selection of high quality and reputable brand name automotive parts and

accessories which we believe will generate DIY customer traffic and also appeal to our Commercial customers. Some of these

brands include Bosch®, Castrol®, Dayco®, Federal-Mogul Moog®, or Moog®, Monroe®, Prestone®, Purolator®, Trico® and

Wagner®. In addition to these branded products, we stock a wide selection of high quality private label products that appeal to

value-conscious customers. These lines of merchandise include chemicals, interior automotive accessories, batteries and parts

under various private label names such as Autocraft®, Driveworks®, Tough One® and Wearever®.

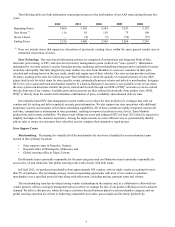

Supply Chain. Our supply chain consists of centralized inventory management and transportation functions which support

a supply chain network of distribution centers, PDQ® warehouses, HUB's and stores. Our inventory management team utilizes

a replenishment system to monitor the distribution center, PDQ® warehouse, HUB and store inventory levels and orders

additional product when appropriate while streamlining handling costs. Our replenishment system utilizes the most up-to-date

information from our POS system as well as inventory movement forecasting based upon sales history, sales trends by SKU,

seasonality (and weather patterns) and demographic shifts in demand. Our replenishment system combines these factors with

service level goals, vendor lead times and cost of inventory assumptions to determine the timing and size of purchase orders.

The vast majority of our purchase orders are sent to our merchandise vendors via electronic data interchange.

During 2012 we opened our Remington, IN distribution center. This distribution center will provide needed capacity to

support our growth and product availability initiatives. It incorporates our new warehouse management system, or WMS, and

state of the art order processing technology which, in addition to the features below, will allow us to provide daily

replenishment to many of the stores served by Remington. Including the Remington facility, we operate nine AAP distribution

centers. All of these distribution centers are equipped with a WMS which provides real-time inventory tracking through the

processes of receiving, picking, shipping and replenishing inventory at our distribution centers. The WMS, integrated with

material handling equipment, reduces warehouse and distribution costs, while improving efficiency. This equipment includes

carousels, “pick-to-light” systems, radio frequency technology, voice technology and automated sorting systems. We have

ongoing supply chain initiatives to further increase the efficient utilization of our distribution capacity including planning for

the roll-out of the advanced technology used at the Remington facility to other facilities in our supply chain network.

Store inventories are replenished from our nine distribution centers. We utilize reputable dedicated carriers to ship product

from our distribution centers to our stores. In addition to a store's normal inventory assortment, we currently offer

approximately 83,000 SKUs to support all of our retail stores via our 22 stand-alone PDQ® warehouses and/or our nine

distribution centers (all of which stock PDQ® items). Stores have visibility, through our EPC system, to inventory in their

respective PDQ® warehouses and distribution centers as well as facilities throughout the Company and can place orders to

these facilities through an online ordering system. Ordered parts are delivered to substantially all stores on a same-day or next-

day basis through our dedicated PDQ® trucking fleet and third-party carriers. Supplementing the inventory on-hand at our

stores, our HUB stores stock an additional 32,000 less common SKUs which are available to our stores within the HUB stores'

service area on a same-day or next-day basis.

Marketing & Advertising. Our marketing and advertising program is designed to drive brand awareness and store traffic

by positioning the Advance Auto Parts brand as the service leader in the aftermarket auto parts category. We strive to exceed

our customers' expectations through our free and value-added services, extensive parts assortment and quality merchandise

offerings.

The 'Service is our best part®' campaign was developed based on extensive research with our customers and Team

Members and has become the Company's promise which has been embraced by each of our 55,000 Team Members. The

campaign targets core DIY and Commercial customers and emphasizes our commitment to provide market-leading service to

our customers. The campaign is built around a multi-channel marketing communication plan which brings together radio, direct

marketing and digital marketing. The plan is supported by in-store and event signage as well as mobile and social media. We

also use Spanish-language television, radio and outdoor advertising to reach our Latino customers.

A final and key component of our advertising is our local marketing program highlighted by our title sponsorship of the

Advance Auto Parts Monster Jam, a live family-oriented monster truck event tour and television show. We are the title sponsor

of the show and as such, the Advance brand is present throughout each host arena and comes alive through the Advance Auto

Parts Grinder monster trucks. We are able to capitalize on the sponsorship at a store level through Grinder and other monster

truck appearances and through store-based customer events in conjunction with the show. In addition, Advance also sponsors

various other grass-roots level events intended to positively impact the individual communities we serve, including Latino and

other ethnic communities, and to drive awareness and repeated store visits.