Mazda 2014 Annual Report Download - page 31

Download and view the complete annual report

Please find page 31 of the 2014 Mazda annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

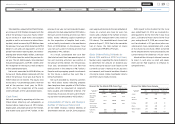

Performance Improve Cost / Efficiency

R&D Efficiency 30% or more

Investment in

Production

Facilities

SKYACTIV-G/D 70% or more

Vehicle 20% or more

Cost

Improvement

Vehicle (excluding

additional equipment)

100kg or more weight reduction (equivalent to

5% fuel economy improvement)

20% or more ¬ 30%

(target)

SKYACTIV-D 20% better fuel economy, Euro6 compliance Better than current engine

SKYACTIV-G 15% better fuel economy and torque, possible to

comply with Euro6

Better than current

direct-injection engine

SKYACTIV-DRIVE 4–7% better fuel economy, direct feeling

improvement

Same as current

transmission

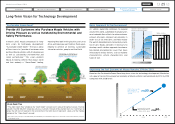

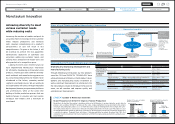

Monotsukuri Innovation

Dramatically improving development and

manufacturing costs

Through Monotsukuri Innovation, our new products

since the CX-5 and SKYACTIV TECHNOLOGY have

achieved improved efficiency in both product devel-

opment and manufacturing facility investment as

well as significant improvements in vehicle costs. For

the new products we plan to introduce in the years to

come, we will maintain and improve quality and

accelerate cost improvements.

Increasing the number of models and parts to

accurately meet increasingly diverse customer

needs reduces productivity and increases

costs. However, compromising on a product’s

attractiveness or cost will result in lost

competitiveness. To grow in the future, it will

be essential to achieve the two apparently

contradictory objectives of optimally and

accurately addressing customer needs, and

utilizing mass production to reduce costs and

offer products at a competitive price.

Looking five to 10 years into the future, we

have implemented Monotsukuri Innovation

for efficiently developing and manufacturing

products, making possible common develop-

ment methods and manufacturing processes

by using integrated planning for models to be

introduced in the future, spanning market

segments and model classes. We are aiming to

raise operational efficiency through integrated

development planning using common platforms

and architectures, while at the same time

building a flexible production process that can

handle changes in volumes and can quickly

introduce new models with a minimum of

investment.

Achieving diversity to meet

various customer needs

while reducing costs

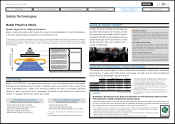

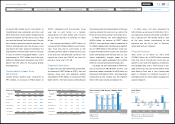

CHECK Example of Monotsukuri Innovation

Mixed Production of SKYACTIV Engines (Flexible Production)

Regardless of whether the engine is gasoline or diesel, or differences in engine capacity, we are able to

process and assemble SKYACTIV engines on the same single production line by considering the engine

structure and production process as a set from the early stages of development. For example, the cylin-

der block processing line used to be a dedicated multiple production line made up of 45 processes, but

we amalgamated the number of processes into four by utilizing generic machinery capable of processing

a variety of engines. Through these initiatives, it became possible to reduce by more than 70% the

amount of facility investment for the installation of a SKYACTIV engine compared with the amount previ-

ously needed.

Aims of and Thinking behind Monotsukuri Innovation

Improvements through Monotsukuri Innovation

Monotsukuri Innovation

Common

Architecture

Concept

Integrated Planning

Flexible Production

Concept

Production Development

Support joint

production

methods that

create economies

of scale

• Common use of

platforms, parts,

and systems with

integrated

planning

• Design that

considers

production lines

• More-efficient production of

various competitive models

Performance

target

Cost target

Improve

performance

Cost

improvement

45 processes

Down by

more than 70%

Previously:

Dedicated

multiple line

SKYACTIV engines:

Utilizing

generic machinery

Previously:

Dedicated

multiple line

SKYACTIV engines:

Utilizing

generic machinery

4

processes

Number of Processes on Cylinder

Block Processing Line

Amount of Facility Investment in

Engine Production Line

Balance conflicting cost improvement

with improved performance through

Monotsukuri Innovation

Target

Previous

Position

Support production of many

competitive products

29

Mazda Annual Report 2014

CONTENTS

Review of Operations

Foundations Underpinning

Sustainable Growth

Message from Management

Introduction

Brand Value Management

Financial Section