Hyundai 2005 Annual Report Download - page 26

Download and view the complete annual report

Please find page 26 of the 2005 Hyundai annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

50

Hyundai Motor Company

Annual Report 2005

>>Sublime Drive

49

Environmental Advancements

Hyundai Motor Company

Environmental Advancements

In 2005 Hyundai Motor Company Chairman and CEO, Chung Mong-Koo launched

our new corporate vision ‘Innovation for Humanity’. This vision was designed to cre-

ate new benchmarks against which all Hyundai operations would be judged.

Chief among these is care and respect for the environment without which there

would be no Hyundai and no humanity. The challenge presented to corporations,

governments and to all people is to find ways to live in harmony with the natural

world and, wherever possible, turn back the planet’s biological clock to a cleaner,

greener world.

As an automobile manufacturer the number one priority of our environmental strate-

gy is the commercialization of eco-friendly vehicles. Hyundai Motor Company con-

tinues to work towards this end with our electric and hybrid car developments,

advancements in diesel engine technologies and our continuing commitment to

end-of-life vehicle disassembly and recycling technologies.

Our financial investment in developing, commercializing and maintaining these tech-

nologies continues in recognition that, for the survival of our company, let alone the

planet, the future must be green.

Developed FGV-1

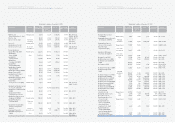

1995 1999 2000 2001 2002 2004 2005

Developed FGV-2 / Developed Elantra hybrid vehicle

Participated in California fuel cell partnership /

Developed Accent hybrid vehicle / Developed County hybrid vehicle /

Developed Santa Fe fuel cell electric vehicle

Accomplished 350 bar hydrogen charge for the

first time in the world (CaFCP)

Developed Getz hybrid vehicle /

Participated in the fuel cell

commercialization project in Japan

The Ministry of Environment’s demonstration of the Getz hybrid vehicle /

Developed the Tucson fuel cell electric vehicle / Validation project of the fuel cell car operation

commissioned by the U.S.A Department of Energy (DOE)

Developed the new Accent hybrid vehicle /

Developed the Tucson fuel cell electric vehicle with

cold startability / Completed the construction of Chino

Hydrogen Energy Station in the U.S.A

1. Hydrogen Fueling Pump

2. Hydrogen Fueling Station in California Tucson fuel cell vehicles to the Alameda-Contra Costa Transit District

in California, as a part of a project commissioned by the U.S.A

Hydrogen Fueling Station in California

As part of the Hydrogen Fleet & Infrastructure

Demonstration and Validation Project, Hyundai

Motor Company completed the construction of its

first hydrogen fueling station located at the

Hyundai & Kia America Technical Center in Chino,

California. A state of the art facility, the fueling sta-

tion produces 15kg of natural gas per day.

Daily fueling capacity is 30 vehicles and fueling

takes roughly 2 minutes to complete. Working in

cooperation with Chevron Texaco, Hyundai Motor

Company has made plans to build more hydrogen

fueling stations in California and other states.

Hyundai Delivers Fuel Cell Vehicles for Exhaustive

Test Program

In December 2005 Hyundai Motor Company deliv-

ered the first of 10 Hyundai Fuel Cell Electric

Vehicles (FCEV) to the Alameda-Contra Costa

Transit District (AC Transit) in Emeryville, California.

The ceremony took place at AC Transit’s

Emeryville Bus Division and marked the beginning

of a five-year demonstration and validation project

designed to evaluate fuel cell vehicles and hydro-

gen infrastructure technologies.

“Hyundai’s partnership with AC Transit represents

the first time that a third-party has been involved in

our fuel cell vehicle research, and it marks another

milestone in our effort to bring this technology to

commercialization,” said Dr. Won Suk Cho, presi-

dent, Hyundai America Technical Center, Inc.,

which is responsible for alternative fuel research in

the U.S.A. “Our vehicles will be operating in

real-world working environments everyday proving

the viability of this technology.”

In April 2004 Hyundai, Chevron Corporation and

UTC Power were awarded a U.S.A Department of

Energy grant to support research into hydrogen-

powered fuel cell technology for automotive

applications. The grant represents U.S.A govern-

ment faith in Hyundai Motor Company to deliver

on its environmental goal of building better and

cleaner vehicles.

Hybrid Electric Vehicle (HEV)

Combines the conventional power-train with the

electric motor and battery system. Offers reduced

improved energy efficiency (greater than 50

percent improvement in fuel economy) and a

reduction in emissions (greater than 15 percent

reduction in fuel emissions). Currently in operation

as Hyundai Accent HEV and Getz HEV. Hyundai

Sonata HEV will be produced from 2007.

Fuel Cell Electric Vehicle (FCEV)

FCEV uses hydrogen, methanol or natural gas as

its main fuel source in reaction with oxygen,

resulting in the outflow of electricity. The FCEV

offers greater re-fueling ease, increased power

and superior performance to its predecessor the

Electric Vehicle (EV). Currently in operation are

Santa Fe FCEV and Tuscon FCEV which features

a start up ability in sub-zero weather.

Gasoline Controlled Auto Ignition (CAI) Engine

Hyundai Motor Company is developing the CAI

Engine to reduce NOx emissions produced from

gasoline engines. The CAI reduces NOx emissions

by over 90 percent compared to existing

conventional engines. In addition, fuel efficiency

improves by 15 percent when the Gasoline Direct

Injection System is applied to the Gasoline CAI

engine

Homogenous Charge Compression Ignition

(HCCI)

Although diesel powered engines achieve higher

efficiency and low emissions, internal combustion

chamber related problems result in excess NOx

emissions. To combat this Hyundai Motor

Company is developing the HCCI Engine to

reduce NOx emissions.

ELV Disassembly Plant

In November 2004, Hyundai Motor Company

completed the construction of the ELV Disassembly

Plant. The plant includes state of the art disposal

equipment and related technologies and has a

maximum recycling capacity of 4,000 vehicles.

Comprising eight phases, the plant includes a

continuous flow disassembly system along with a

system which monitors recycling.

Vehicle Recycling

Hyundai Motor Company is developing various

waste parts recycling technologies for use in the

production of new vehicles. In line with its plastic

and rubber recycling initiatives, Hyundai Motor

Company recycles vehicle carpets and seating

foam and reuses parts in trunk trim and noise

reducing padding parts. In addition, Hyundai

Motor Company will introduce a new recycling

system for waste bumpers from 2005. The system

allows for large scale re-circulation of materials

from used bumpers and for the elimination of

disposal wastes through recycling.

Catalysts Recycling

Platinum Group Metals (PGM) are used as the

main catalyst to refine petroleum and purify

emissions. Due to rising global demand and the

relatively high cost of PGM, recycling initiatives

have been set as a major priority. In partnership

with suppliers, Hyundai Motor Company estab-

lished a joint venture which became the first

domestic environmentally friendly PGM recycling

company. This joint venture allows for Hyundai

Motor Company to achieve cost savings and

reductions and continued progress in the

domestic automobile industry.

1 2