Mazda 2016 Annual Report Download - page 27

Download and view the complete annual report

Please find page 27 of the 2016 Mazda annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

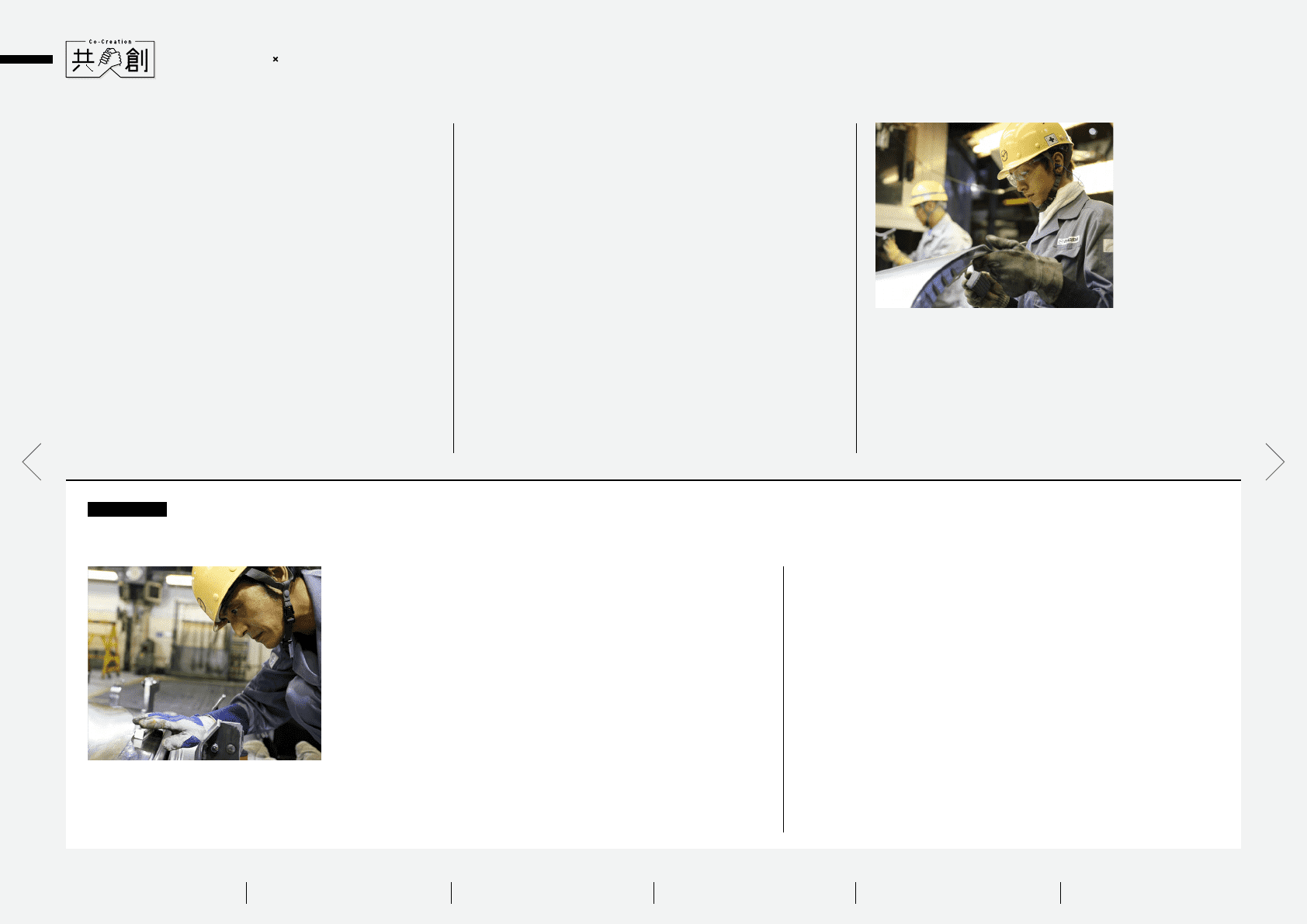

Maintaining press molds

Mazda’s “artisan skills” create forms that are filled with KODO design’s sense of vitality in units of 1/1,000th of a millimeter

technology was created to achieve a three-dimensional

form befitting a sports car.

One of the major changes made on the manufactur-

ing line was to alter the form of procurement for alumi-

num from the previous sheets to coils. Also, by bringing

the aluminum cutting process in-house and setting up a

sophisticated cutting line prior to the pressing of the

front fenders, we were able to increase yields*1 15%.

With regard to the aluminum cutting line, capital

expenditure was kept to a minimum by remodeling the

previous steel cutting line so that it could handle both

steel and aluminum. Some of the many difficult issues

stemming from the different properties of steel and

aluminum that needed to be resolved when carrying

out this line remodeling were that aluminum is softer

and scratches more easily than steel, it is not magnetic,

and more shavings are created when cutting, making it

more difficult to maintain molds. These issues were

overcome through workplace knowledge and ingenuity,

and the line remodeling was successful.

As a result, lightweight fenders that improve vehicle

performance were created in a cost-efficient manner.

The success achieved in the new MX-5 is applied to

other models and contributes to making Mazda’s entire

lineup more lightweight.

*1 The ratio of material that actually becomes product. A higher yield means lower

costs and also helps to reduce the energy used in recycling the unused portion.

Kimio Dojo

Artisan for press mold maintenance

Checking the quality of a pressed aluminum front fender

Work related to restoring the shape of a molded product

CLOSE UP

Design Divisions Manufacturing Divisions

In order to create an automobile that conveys the rich expressions

and strong vitality that can only be found in living things, Mazda’s

KODO design is insistent on artistic forms that can only be created

by human beings.

Pressing based on very minute calculations and using highly

precise molds is indispensable in creating forms full of vitality

developed by designers and engineers from various areas and

using these forms to produce piece-by-piece body parts that

achieve the desired form.

With the shape of press-molded body parts such as front

fenders, a difference of only 1/1,000th of a millimeter caused by the

wear from abrasion with the aluminum, steel, or other material

being pressed can directly affect the beauty or quality of the body.

When these minute changes are detected in a mold, various tools

are used to produce the desired shape. This is the job of Kimio Dojo,

the on-site staff member responsible for press mold maintenance.

To reproduce the highly precise, flowing shape of KODO design,

which consists of continuous curves, the final step of mold mainte-

nance is performed by sight and touch alone. The delicate skill of a

worker surpasses the ability of high-precision measuring equipment.

Dojo notes:

“KODO design involves sharp contrasts of light and shadows, with

an uninterrupted flow of beautiful reflections of scenery. To con-

tinue to preserve this design, therefore, I strive to maintain continu-

ous, completely fluid, beautiful curves, without any compromise.”

MAZDA ANNUAL REPORT 2016

25 Drivers of Value Creation

Message from

Management

Review of Operations

Foundations Underpinning

Sustainable Growth

Financial Section

Contents