Mazda 2016 Annual Report Download - page 24

Download and view the complete annual report

Please find page 24 of the 2016 Mazda annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Monotsukuri Innovation

CHECK Integrated Planning / Common Architecture

– Design intent faithfully reproduces in mass-production vehicles

– Development and application of designer colors Soul Red and Machine Gray contribute to enhancing brand value

Efforts to realize high levels of diversity, which enhances

the competitive edge of our products, and commonality,

which boosts the efficiency of mass production

Looking five to 10 years into the future, we have implemented Monotsu-

kuri Innovation for efficiently developing and manufacturing products,

making possible common development methods and manufacturing

processes by using integrated planning for models to be introduced in the

future, spanning market segments and model classes.

Optimized structures of each function are shared across all car lines

and laterally spread to each car line based on the integrated planning.

A flexible production system is used to produce products engineered

based on a common architecture concept in a highly efficient and flexible

way. We are aiming to raise operational efficiency through building a

flexible production process that can handle changes in volumes and can

quickly introduce new models with a minimum of investment.

Monotsukuri Innovation enabled Mazda to make more competitive products while

improving costs

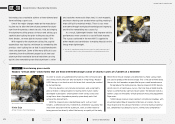

CHECK New Design Color: Machine Gray

Under the idea that color is one of the elements of form, Mazda has been focusing its efforts

on developing colors, such as Soul Red, and coating technologies that accentuate the subtle

yet dynamic surfacing of KODO design. The new design color Machine Gray, which is slated to

be used for new model CX-9 and MX-5 RF, was developed to express the beauty of a machine’s

strength and precision. With strong contrast between light and shadow and a sleek, high-densi-

ty finish, Machine Gray gives the impression that the vehicle’s body has been sculpted from a

solid steel ingot. As a color that complements the KODO design, Machine Gray is contributing

to improvements in brand value.

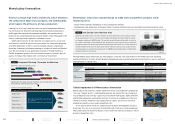

Performance Improve Cost / Efficiency

R&D efficiency 30% or more

Investment in

production

facilities

SKYACTIV-G/D 70% or more

Vehicle 20% or more

Cost

improvement

Vehicle

(excluding additional equipment)

100kg or more weight reduction

(equivalent to 5% fuel economy improvement)

20% or more ¬ 30% (target)

SKYACTIV-D 20% better fuel economy, Euro6 compliance Better than previous engine

SKYACTIV-G 15% better fuel economy and torque, possible to comply

with Euro6

Better than previous direct

injection engine

SKYACTIV-DRIVE 4%–7% better fuel economy, direct feeling improvement Same as previous transmission

AFTER: Total Optimization

Engine series

Transmissions

Body series

Chassis series

Other components

One R&D / production concept for

all car lines

Pursue scale merits for entire lineup

Integrated Planning: Looking at trends 5 to 10 years ahead

SUV

C/D

C

B

BEFORE: Separate Optimization

C

B

C/D

SUV

ProductionR&D

ProductionR&D

ProductionR&D

ProductionR&D

Optimized structures of each function are shared across all car lines

and laterally spread to each car line.

SUV

C/D

C

B

Through Monotsukuri Innovation, our new products since the CX-5 and SKYACTIV TECHNOLOGY have achieved

improved efficiency in terms of both product development and manufacturing facility investment as well as significant

improvements in vehicle costs.

Monotsukuri Innovation has yielded significant results at our domestic production

sites (our “mother plants”), and going forward we will expand this to include over-

seas production sites and our supply chain to achieve high-quality, highly efficient,

and flexible production and improve the cost structure on a global basis. We also

intend to increase flexibility in our production of sedans and SUVs to maximize

production capacity at our major production sites.

As we pursue these initiatives, global human resource development will play a

major role. Our aim is to create an environment and structure in which employees

who understand and share the Mazda vision are able to stand out and play a role at

overseas production sites.

Global deployment of Monotsukuri Innovation

Mexico Plant

MX-5 RF

MAZDA ANNUAL REPORT 2016

22 Drivers of Value Creation

Message from

Management

Review of Operations

Foundations Underpinning

Sustainable Growth

Financial Section

Contents