BMW 2008 Annual Report Download - page 31

Download and view the complete annual report

Please find page 31 of the 2008 BMW annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

32

14 Group Management Report

14 A Review of the Financial Year

16 General Economic Environment

20 Review of Operations

42 BMW Stock and Bonds

45 Disclosures pursuant to § 289 (4)

and § 315 (4) HGB

47 Financial Analysis

47 Internal Management System

49 Earnings Performance

51 Financial Position

52 Net Assets Position

55 Subsequent Events Report

55 Value Added Statement

57 Key Performance Figures

58 Comments on BMW AG

62 Risk Management

68 Outlook

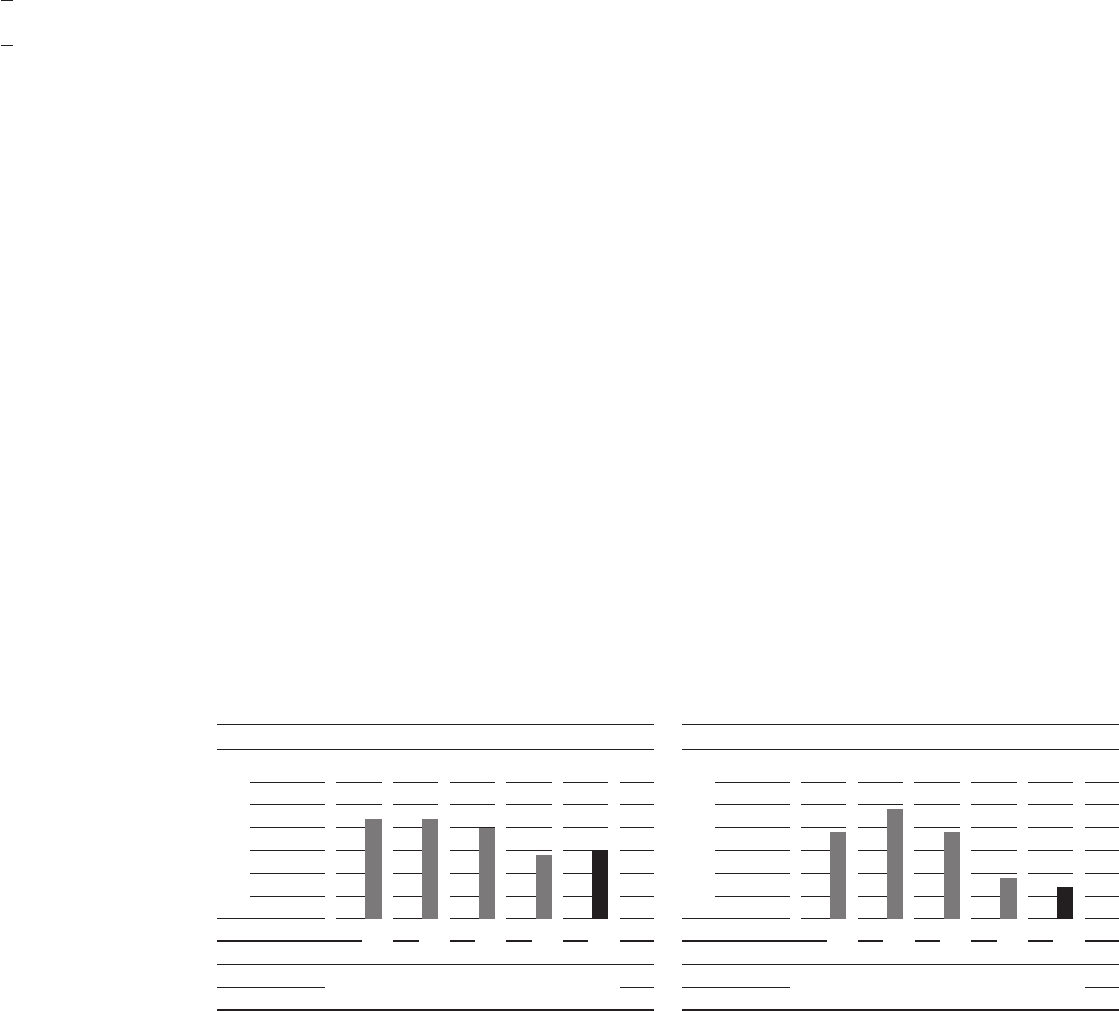

Energy consumed per vehicle produced

in MWh / vehicle

3.10

3.00

2.90

2.80

2.70

2.60

04 05 06 07

* 08

2.94 2.94 2.90 2.78 2.80

*

Basis for data expanded in from ten to locations. Until : Munich,

Dingolfing, Landshut, Regensburg, Leipzig, Steyr, Rosslyn, Spartanburg, Hams Hall,

Oxford. Since :

Berlin (brake disc production), Eisenach, Swindon, Goodwood,

Rayong (assembly), Chennai

(assembly) and BMW Brilliance in Shenyang.

CO emissions per vehicle produced

in t / vehicle

1.05

1.00

0.95

0.90

0.85

0.80

04 05

1 06 07

2

08

0.94 0.99 0.94 0.84 0.82

The increase is attributable to a change in the energy mix.

B

asis for data expanded in from ten to locations. Until : Munich,

Dingolfing, Landshut, Regensburg, Leipzig, Steyr, Rosslyn, Spartanburg, Hams Hall,

Oxford. Since :

Berlin (brake disc production), Eisenach, Swindon, Goodwood,

Rayong (assembly), Chennai

(assembly) and BMW Brilliance in Shenyang.

Further enhancements in environmentally

compatible vehicle design

The BMW Group again set new milestones in improving

the environmental compatibility of its products in .

One example of this is the creation of a comprehensive

product data system containing details of the material

composition of all components used in a vehicle. In May

, with the help of this system, the BMW Group became

the first carmaker to present a virtual “material balance

sheet” (for the new BMW 7 Series) conforming to interna-

tional standard ISO .

Furthermore, in a large-scale industrial trial, the BMW

Group was able to demonstrate that, with the aid of post-

shredder technology, BMW Group-manufactured cars

are at least recyclable and up to recoverable. Un-

der the post-shredder method (after vehicles have been

dismantled and shredded mechanically), shredder residue

fractions are sorted and sifted into their various constituent

materials such as metals, plastics and minerals, in prepara-

tion for further processing.

Thanks to the extensive preparatory work carried out, the

BMW Group passed the preliminary tests of the relevant

licensing agency in May . The BMW Group therefore

complies with the regulations of the European Directive

/ / EG on type approval of motor vehicles with regard

to their reusability, recyclability and recoverability. The use

of recovered materials (recyclates) was also increased in

. The proportion of recyclates used in the new BMW

7 Series for instance was increased by approximately

compared to the preceding model. The use of quality-ap-

proved recyclates reduces costs and preserves resources

while still ensuring compliance with established quality

standards.

Strict management of environmental care activities

The BMW Group applies the “Clean Production” phi-

losophy to its production activities. In line with this forward-

looking commitment to environmental care, the BMW

Group endeavours to achieve systematic and consistent

reductions in the volume of resources used and to lessen

the impact of production activities on the environment.

In order to monitor this, environmentally relevant indicators

are measured automatically and reported on a monthly

basis.

The following key indicators – expressed as amounts per

vehicle produced – are integral components of the group-

wide target system and are managed accordingly:

– energy consumption

– water consumption

– process wastewater

– solvent emissions

– waste for disposal

CO emissions per vehicle produced are also recorded

based on the amount of energy consumed and the energy

mix used.

The target for the global production network is to reduce

these key indicators by between and . This

entails achieving an average reduction of p. a. These

targets can, however, vary as a result of model production

start-ups, discontinuations or changed production vol-

umes. The reduction across all key indicators is additionally

examined on the basis of an Environmental Efficiency

Ratio (EER). The EER computation for showed that

the improvement in resource efficiency remained within

the agreed target corridor.