Spirit Airlines 2013 Annual Report Download - page 42

Download and view the complete annual report

Please find page 42 of the 2013 Spirit Airlines annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.42

fluctuations of costs) of providing services, volume of marketing efforts and overall advertising plan. Consideration allocated

based on the relative selling price to both brand licensing and advertising elements is recognized as revenue when earned and

recorded in non-ticket revenue. Consideration allocated to award miles is deferred and recognized ratably as passenger revenue

over the estimated period the transportation is expected to be provided which is currently estimated at 16 months. We used

entity-specific assumptions coupled with the various judgments necessary to determine the selling price of a deliverable in

accordance with the required selling price hierarchy. Changes in these assumptions could result in changes in the estimated

selling prices. Determining the frequency to reassess selling price for individual deliverables requires significant judgment. For

additional information, please see “Notes to Financial Statements—1. Summary of Significant Accounting Policies—Frequent

Flier Program”.

Aircraft Maintenance, Materials, Repair Costs and Related Heavy Maintenance Amortization. We account for heavy

maintenance under the deferral method. Under the deferral method the cost of heavy maintenance is capitalized and amortized

as a component of depreciation and amortization expense until the earlier of the next estimated heavy maintenance event or the

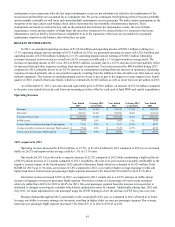

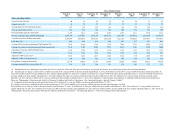

aircraft's return at the end of the lease term. Amortization of engine and aircraft overhaul costs was $23.6 million, $9.1 million

and $2.6 million for the years ended December 31, 2013, 2012 and 2011, respectively. If heavy maintenance costs were

amortized within maintenance, material and repairs expense in the statement of operations, our maintenance, material and

repairs expense would have been $83.8 million, $58.6 million and $36.6 million for the years ended December 31, 2013, 2012

and 2011, respectively. During the years ended December 31, 2013, 2012 and 2011, we capitalized $70.8 million, $61.6 million

and $22.1 million of costs for heavy maintenance, respectively. The timing of the next heavy maintenance event is estimated

based on assumptions including estimated usage, FAA-mandated maintenance intervals and average removal times as

suggested by the manufacturer. These assumptions may change based on changes in our utilization of our aircraft, changes in

government regulations and suggested manufacturer maintenance intervals. In addition, these assumptions can be affected by

unplanned incidents that could damage an airframe, engine or major component to a level that would require a heavy

maintenance event prior to a scheduled maintenance event. To the extent our planned usage increases, the estimated life would

decrease before the next maintenance event, resulting in additional expense over a shorter period. Heavy maintenance events

are our 6-year and 12-year airframe checks (HMV4 and HMV8, respectively), engine overhauls and overhauls to major

components. Certain maintenance functions are outsourced under contracts that require payment based on a performance

measure such as flight hours. Costs incurred for maintenance and repair under flight hour maintenance contracts, where labor

and materials price risks have been transferred to the service provider, are accrued based on contractual payment terms. Routine

cost for maintaining the airframes and engines and line maintenance are charged to maintenance, materials and repairs expense

as performed.

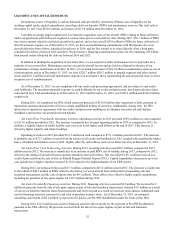

Maintenance Reserves. Some of our master lease agreements provide that we pay maintenance reserves to aircraft lessors

to be held as collateral in advance of our performance of major maintenance activities. These lease agreements provide that

maintenance reserves are reimbursable to us upon completion of the maintenance event in an amount equal to the lesser of (1)

the amount of the maintenance reserve held by the lessor associated with the specific maintenance event or (2) the qualifying

costs related to the specific maintenance event. Substantially all of these maintenance reserve payments are calculated based on

a utilization measure, such as flight hours or cycles and are used solely to collateralize the lessor for maintenance time run off

the aircraft until the completion of the maintenance of the aircraft.

At lease inception and at each balance sheet date, we assess whether the maintenance reserve payments required by the

master lease agreements are substantively and contractually related to the maintenance of the leased asset. Maintenance reserve

payments that are substantively and contractually related to the maintenance of the leased asset are accounted for as

maintenance deposits. Maintenance deposits expected to be recovered from lessors are reflected as prepaid maintenance

deposits in the accompanying balance sheets. When it is not probable we will recover amounts currently on deposit with a

lessor, such amounts are expensed as supplemental rent. Because we are required to pay maintenance reserves for our operating

leased aircraft, and we choose to apply the deferral method for maintenance accounting, management expects that the final

heavy maintenance events will be amortized over the remaining lease term rather than over the next estimated heavy

maintenance event. As a result, our maintenance costs in the last few years of leases could be significantly in excess of the costs

in earlier periods. In addition, these late periods could include additional costs from unrecoverable maintenance reserve

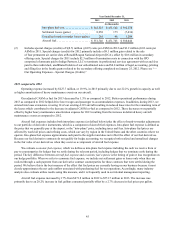

payments required in the late years of the lease. We expensed $1.9 million, $2.0 million and $1.5 million of paid maintenance

reserves as supplemental rent during 2013, 2012 and 2011, respectively.

As of December 31, 2013 and 2012, we had prepaid maintenance deposits of $220.7 million and $198.5 million,

respectively, on our balance sheets. We have concluded that these prepaid maintenance deposits are probable of recovery

primarily due to the rate differential between the maintenance reserve payments and the expected cost for the related next

maintenance event that the reserves serve to collateralize.

These master lease agreements also provide that most maintenance reserves held by the lessor at the expiration of the

lease are nonrefundable to us and will be retained by the lessor. Consequently, we have determined that any usage-based