Family Dollar 2010 Annual Report Download - page 11

Download and view the complete annual report

Please find page 11 of the 2010 Family Dollar annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

We purchase merchandise from a wide variety of suppliers and generally have not experienced difficulty in

obtaining adequate quantities of merchandise. In fiscal 2010, no single supplier accounted for more than 9% of

the merchandise sold by us. We imported approximately 9% of our merchandise purchases (at cost) during fiscal

2010. While most of our merchandise is shipped to our distribution centers from domestic suppliers, a substantial

amount of such merchandise is manufactured outside the United States and imported by the domestic suppliers.

Our vendor arrangements provide for payment in U.S. dollars.

We maintain a substantial variety and depth of merchandise inventory in stock in our stores (and in our

distribution centers for weekly store replenishment) to attract customers and meet their shopping needs. We

negotiate vendors’ trade payment terms to help finance the cost of carrying this inventory. We balance the value

of maintaining high inventory levels required to meet customer demand with the potential risk of having

inventories at levels that exceed such demand and that may need to be marked down in price in order to sell.

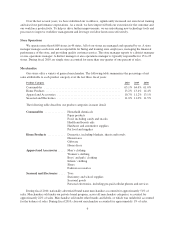

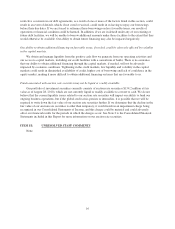

Distribution and Logistics

During fiscal 2010, the manufacturer or distributor shipped approximately 7% of our merchandise purchases

directly to stores. The balance of the merchandise was shipped to one of our nine distribution centers listed

below. To provide consistent, cost-effective service, we enlist the services of several national transportation

companies throughout the U.S. as well as our own private fleet of trucks to deliver merchandise to stores from

our distribution centers. During fiscal 2010, approximately 92% of the merchandise sent from our distribution

centers to our stores was delivered by common or contract carriers. At the end of fiscal 2010, the number of

stores served by each of our distribution centers was as follows:

Distribution Center

Number of Stores

Served

Matthews, NC ........................................................ 739

West Memphis, AR .................................................... 615

Front Royal, VA ...................................................... 817

Duncan, OK .......................................................... 749

Morehead, KY ........................................................ 941

Maquoketa, IA........................................................ 809

Odessa, TX .......................................................... 774

Marianna, FL ......................................................... 674

Rome, NY ........................................................... 667

Total ........................................................... 6,785

Technology

We utilize a variety of technological systems to conduct our business, including point-of-sale technology,

inventory management tools, supply chain systems, and financial and human resource applications.

During fiscal 2010, we completed the roll-out of new register and point-of-sale technology in our stores.

The new technology platform facilitates the acceptance of additional payment types, including credit cards and

food stamps, and includes a number of computer-based tools designed to provide our store managers with better

training, analytics and workflow management.

We maintain by-item inventories for all stores and employ a demand forecasting system for replenishment

of our distribution centers. We also utilize software applications for centralized store replenishment of basic

merchandise and for allocation of non-basic merchandise. We have centralized merchandise financial planning,

assortment optimization, price optimization, and space management applications and processes. These systems

aid us in the planning and forecasting of sales, cost of sales and inventory metrics by product category to position

us to achieve our financial goals and to ensure proper allocation and flow of inventory. These systems allow us to

optimize merchandise in-stock positions in stores, reduce markdowns and improve inventory turnover.

7