Pentax 2006 Annual Report Download - page 31

Download and view the complete annual report

Please find page 31 of the 2006 Pentax annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Environmental Initiatives

The Hoya Group believes that the expanding scale of a company’s business operations must be matched by the willingness

to take on greater and greater responsibility for issues of social concern, such as environmental protection. Hoya pursues

business growth with full consideration for the earth’s precious environment, and has stated as much in its philosophy on

protecting the environment. In 1976, Hoya established pollution countermeasure committees at each of its plants, and has

been engaged ever since in a variety of initiatives to protect the environment and conserve natural resources. A few of

those initiatives are introduced below.

1. Reduction of Environmental Impact

Hoya has identified the four main areas where its production activities have an

environmental impact—levels of energy consumption, water usage, waste

volume, and volume of packaging materials—and is pushing ahead with

measures to reduce impact in all of these areas.

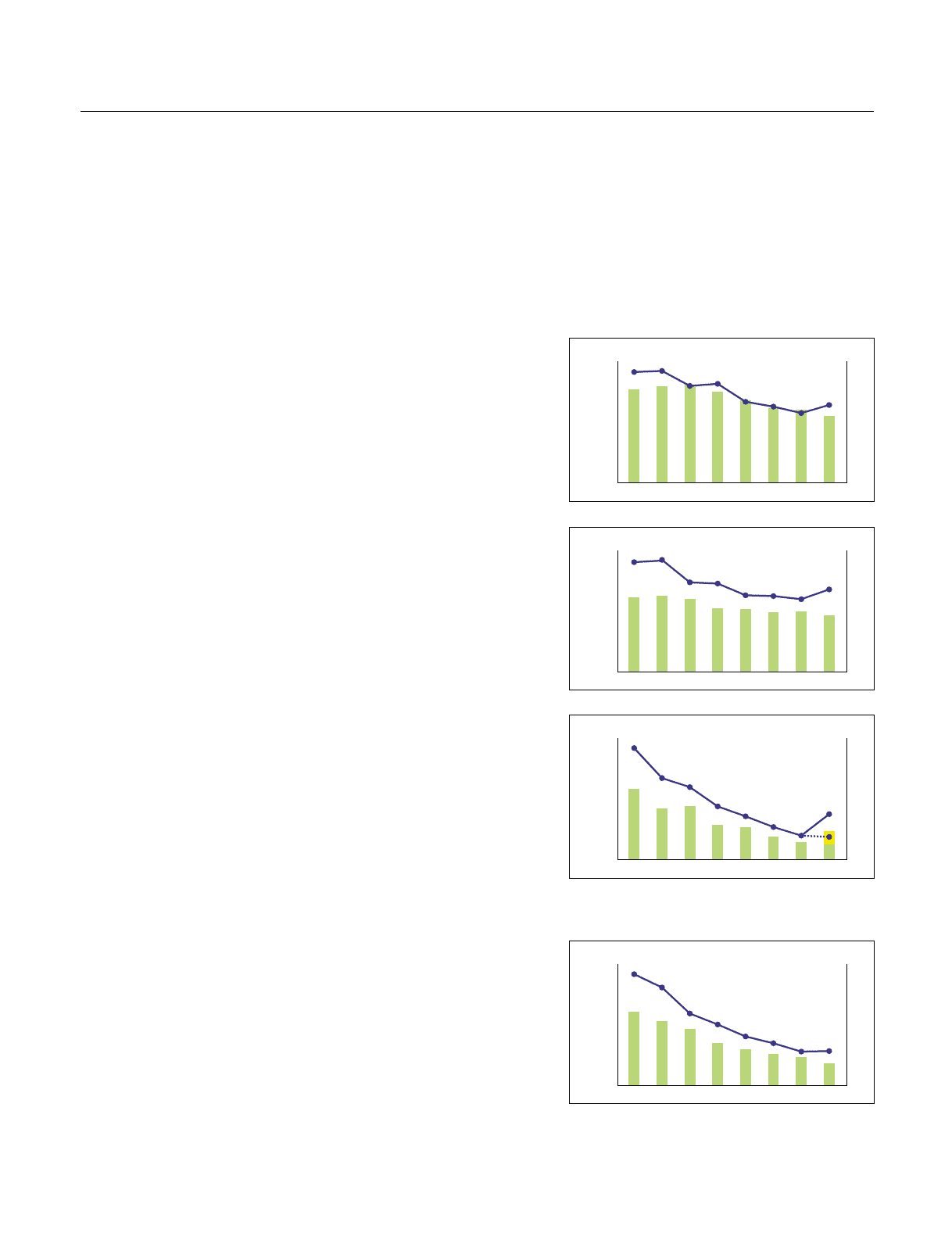

Energy Consumption

Hoya has implemented a number of energy-saving initiatives at its facilities, including

the introduction of ice thermal storage systems and high efficiency electrical

transformers. Along with these steps, Hoya has also introduced rooftop gardening

at factory buildings, casual days in the office on ordinary work days in summer.

Efforts such as these are examples of the steps that Hoya has taken across all of its

businesses to conserve energy. In the term under review, Hoya reduced energy

usage levels 8% from the previous year, although the ratio of energy usage to net

sales increased by approximately 11%.

Water Usage

Through ongoing efforts for the re-use of factory waste water and the introduction of

automated water faucet control in washroom hand basins, water usage decreased by

7% year on year, but rose by 13% when expressed as a ratio to net sales.

Waste Volume

In the fiscal year under review, the Musashi Plant building was dismantled and

production was moved to Akishima-shi in metropolitan Tokyo, so there was a large

increase in the volume of waste. As a result, a large increase in waste volume was

recorded. Regarding other wastes, however, efforts were made to reduce waste

volume on a number of fronts, including recycling of sludge from polishing as raw

material for concrete and thermal recycling of waste plastics. The volume of waste

was reduced by around 29%, or about 13% when expressed as a ratio to net sales.

Volume of Packaging Materials

Thanks to activities such as promoting the re-use of cardboard packing boxes, the

volume of packaging materials used fell by 21% year on year, and was about level

with last year when expressed as a ratio to net sales.

2. Introduction of Environmental Management

Systems (ISO 14001 Certification)

In October 1996, the Hoya Group announced plans to make its environmental

management systems compliant with ISO 14001 certification standards, and in

December 1997 the plant run by HOYA LENS DEUTSCHLAND GmbH (in

Germany) became the first to gain such certification. Since then, the Hoya

Group has pushed forward according to plan toward the certification of all

production plants, including those located overseas. By the end of March 2001,

nearly all mass production plants in Japan and abroad had been certified. As of

the end of March 2006, a total of 35 plants belonging to the Hoya Group had

been certified (11 in Japan, 24 abroad).

Energy Consumption (Oil Conversion) and Its Ratio to Net Sales

100,000

80,000

60,000

40,000

20,000

0

100

80

60

40

20

0

(Oil conversion kl) (Ratio to net sales [1999=100])

Water Use and Its Ratio to Net Sales

4,000

3,000

2,000

1,000

0

100

80

60

40

20

0

(km3)(Ratio to net sales [1999=100])

Packaging Materials and Their Ratio to Net Sales

1999 2000 2001 2002 2003 2004 2005 2006

4,000

3,000

2,000

1,000

0

100

80

60

40

20

0

(Tons) (Ratio to net sales [1999=100])

Notes: 1. Ratio to net sales indicated based on 1999=100. Please also note

that Hoya uses units of millions of yen to calculate ratios to net sales.

2. Statistics of the nine domestic production sites; Nagasaka, Hachioji,

Kumamoto, Akishima, Nagano, Lens Technology Center, Minakuchi,

Musashi (currently Tokyo Studio), Kodama.

Waste Volume and Its Ratio to Net Sales

10,000

8,000

6,000

4,000

2,000

0

(Tons) (Ratio to net sales [1999=100])

The yellow portion is the transient construction scrap wood and others accompanying

the Musashi factory relocation conducted during the fiscal year ended March 2006,

and the sales unit index except a transient factor is expressed as the dotted line.

100

80

60

40

20

0

1999 2000 2001 2002 2003 2004 2005 2006

1999 2000 2001 2002 2003 2004 2005 2006

1999 2000 2001 2002 2003 2004 2005 2006