Pentax 2006 Annual Report Download - page 17

Download and view the complete annual report

Please find page 17 of the 2006 Pentax annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

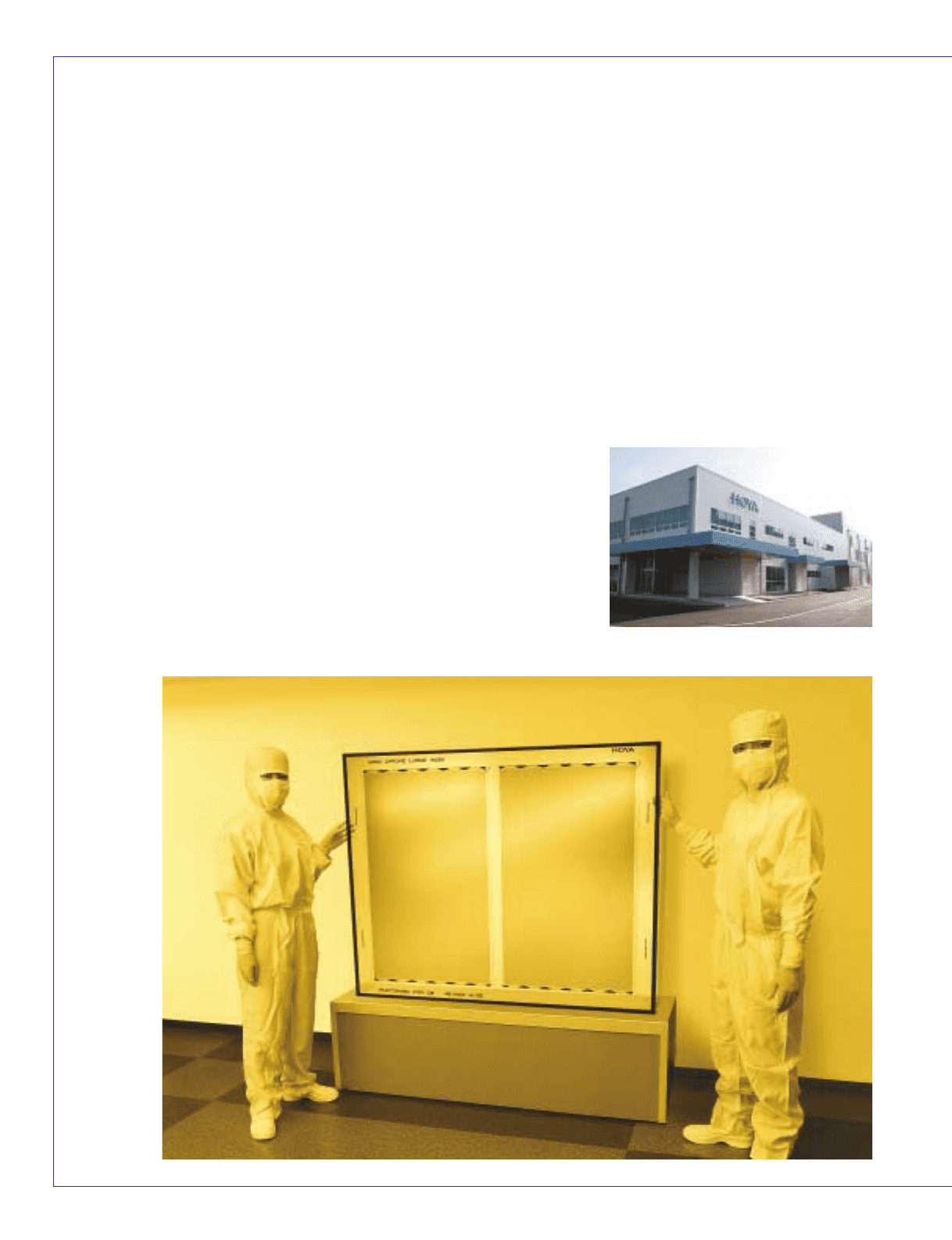

LCD Photomasks

LCD photomasks are the large-sized photomasks inscribed with the patterns used for the production of LCD panels. LCD televisions,

which are increasing in size year by year, play a large part in boosting demand for LCD panels, and there is a corresponding growth in

demand for ever larger photomasks for use in the production of those panels. Because the degree of precision demanded of large

LCD panels is comparable with that required of semiconductor chips, Hoya, which produces photomasks for semiconductors, is well

placed to use the same technologies to meet market needs.

Supplementing its plants in Kumamoto, Japan and Taiwan, Hoya opened a new plant in South Korea in October 2005, bringing to

three the number of LCD photomask production facilities. Because all three plants are close to their respective LCD panel

manufacturers, the Company can develop products that meet the needs of each market and shorten delivery time frames. Hoya will

continue to improve its competitive strengths using this approach.

LCD panels are classified according to their size as fifth-generation, sixth-generation and so on*1. In 2006, full-scale commercial

production will begin for seventh-generation panels, and production of eighth-generation panels is also expected to be brisk during 2007.

In response to this expanding demand for large panels and to ensure that Hoya builds a dominant position for itself in comparison with

the competition, the Company has set a number of operational objectives. On the technical side, these include the development of high-

value-added technology, which can best be represented by the multi-tone mask*2.

On the production side, Hoya will enhance competitiveness by improving the

production efficiencies and effectively managing its three-plant system.

South Korea plant

Large-sized LCD photomask (1,220mm x 1,400 mm) used for eighth-generation LCD panels.

Notes:

*1. Panel manufacturers’ mother glass plate sizes:

Fifth-generation: 1,100 mm x 1,300 mm (yielding three 32-inch wide LCD television panels).

Sixth-generation: 1,500 mm x 1,850 mm (yielding eight 32-inch wide LCD television panels).

Seventh-generation: 1,870 mm x 2,200 mm (yielding three 50-inch wide LCD television panels).

Eighth-generation: 2,160 mm x 2,400 mm (yielding six 50-inch wide LCD television panels).

*2. A photomask that allows for mid-range light penetration through miniaturization of patterns and semi-

transparent film. Use of this mask reduces the number of lithographic processes for TFT LCD panels

from five to four, contributing to production efficiencies and cost reductions for panel manufacturers.