Audi 2006 Annual Report Download - page 141

Download and view the complete annual report

Please find page 141 of the 2006 Audi annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

1 3 9

Environmental management

Sustainable management is an integral component of the Audi Group strategy and strives to

reconcile environmental protection with innovations. Through its pioneering technical inno-

vations, the Audi Group is contributing towards major advances in protecting the environ-

ment and displays the European Union’s symbol of environmental excellence. This gives

customers the reassurance that optimum environmental compatibility was heeded in the

manufacturing of their vehicle, alongside such aspects as durability, quality and safety.

Environmental protection organisation of the Audi Group

Work group: End-of-Life Vehicles

Work group: Sustainability

Work group: Environmental Report

Work group: Environmental Management

Work group: IPP

Steering Committee

for Ecology

AUDI AG

Production plants:

Ingolstadt,

Neckarsulm

(Germany)

Environmental

Management Officer

AUDI HUNGARIA

MOTOR Kft.

Production plant:

Győr (Hungary)

Environmental

Management Officer

Automobili Lamborghini

Holding S.p.A.

Production plant:

Sant´Agata Bolognese

(Italy)

Coordinating Committee for Environmental Protection

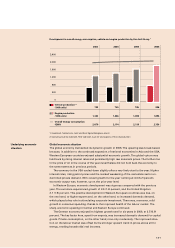

The Audi Group is among the pioneers of location-based environmental protection both in

Germany and internationally.

AUDI AG for example covers up to 95 percent of the overall water requirements of its

production facilities at Ingolstadt within a closed cycle and conducts analyses to verify that

the specified limit values for waste water are complied with. A modern, ultra-efficient emul-

sion evaporation plant for the physical treatment of the emulsions and wash water arising at

the location was moreover opened in March 2006. This cut such components as the trans-

port costs for their disposal by around 70 percent.

A new waste water treatment plant in which process water is purified was opened at

Neckarsulm. This investment, costing EUR 3.7 million, significantly boosted the output of

the central industrial waste water treatment plant. Saving energy at engine test rigs at

Neckarsulm furnishes another example. At the new engine test rig centre, the electrical

energy that is generated by the electric machines during testing of the internal combustion

engines is used to cover the energy requirements of the building’s technical facilities in full.

This represents an efficient form of energy recovery.

Complex recycling management arrangements also now help to avoid waste at AUDI

HUNGARIA MOTOR Kft. in Győr, Hungary. Recycling management includes for instance

comprehensively checking the waste that arises until it reaches the point of its re-use, and

the delivery of components in returnable packaging. Predominantly emissions-free cold

tests are used as a means of minimising the environmental impact of developing and test-

ing engines. The recovery of heat means that the waste air from the production halls serves

as an additional source of energy.

Environmental aspects