Honeywell 2008 Annual Report Download - page 17

Download and view the complete annual report

Please find page 17 of the 2008 Honeywell annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.-

1

1 -

2

2 -

3

3 -

4

4 -

5

5 -

6

6 -

7

7 -

8

8 -

9

9 -

10

10 -

11

11 -

12

12 -

13

13 -

14

14 -

15

15 -

16

16 -

17

17 -

18

18 -

19

19 -

20

20 -

21

21 -

22

22 -

23

23 -

24

24 -

25

25 -

26

26 -

27

27 -

28

28 -

29

29 -

30

30 -

31

31 -

32

32 -

33

33 -

34

34 -

35

35 -

36

36 -

37

37 -

38

38 -

39

39 -

40

40 -

41

41 -

42

42 -

43

43 -

44

44 -

45

45 -

46

46 -

47

47 -

48

48 -

49

49 -

50

50 -

51

51 -

52

52 -

53

53 -

54

54 -

55

55 -

56

56 -

57

57 -

58

58 -

59

59 -

60

60 -

61

61 -

62

62 -

63

63 -

64

64 -

65

65 -

66

66 -

67

67 -

68

68 -

69

69 -

70

70 -

71

71 -

72

72 -

73

73 -

74

74 -

75

75 -

76

76 -

77

77 -

78

78 -

79

79 -

80

80 -

81

81 -

82

82 -

83

83 -

84

84 -

85

85 -

86

86 -

87

87 -

88

88 -

89

89 -

90

90 -

91

91 -

92

92 -

93

93 -

94

94 -

95

95 -

96

96 -

97

97 -

98

98 -

99

99 -

100

100 -

101

101 -

102

102 -

103

103 -

104

104 -

105

105 -

106

106 -

107

107 -

108

108 -

109

109 -

110

110 -

111

111 -

112

112 -

113

113 -

114

114 -

115

115 -

116

116 -

117

117 -

118

118 -

119

119 -

120

120 -

121

121 -

122

122 -

123

123 -

124

124 -

125

125 -

126

126 -

127

127 -

128

128 -

129

129 -

130

130 -

131

131 -

132

132 -

133

133 -

134

134 -

135

135 -

136

136 -

137

137 -

138

138 -

139

139 -

140

140 -

141

141 -

142

142 -

143

143 -

144

144 -

145

145 -

146

146 -

147

147 -

148

148 -

149

149 -

150

150 -

151

151 -

152

152 -

153

153 -

154

154 -

155

155 -

156

156 -

157

157 -

158

158 -

159

159 -

160

160 -

161

161 -

162

162 -

163

163 -

164

164 -

165

165 -

166

166 -

167

167 -

168

168 -

169

169 -

170

170 -

171

171 -

172

172 -

173

173 -

174

174 -

175

175 -

176

176 -

177

177 -

178

178 -

179

179 -

180

180 -

181

181 -

182

182 -

183

183 -

184

184 -

185

185 -

186

186 -

187

187 -

188

188 -

189

189 -

190

190 -

191

191 -

192

192 -

193

193 -

194

194 -

195

195 -

196

196 -

197

197 -

198

198 -

199

199 -

200

200 -

201

201 -

202

202 -

203

203 -

204

204 -

205

205 -

206

206 -

207

207 -

208

208 -

209

209 -

210

210 -

211

211 -

212

212 -

213

213 -

214

214 -

215

215 -

216

216 -

217

217 -

218

218 -

219

219 -

220

220 -

221

221 -

222

222 -

223

223 -

224

224 -

225

225 -

226

226 -

227

227 -

228

228 -

229

229 -

230

230 -

231

231 -

232

232 -

233

233 -

234

234 -

235

235 -

236

236 -

237

237 -

238

238 -

239

239 -

240

240 -

241

241 -

242

242 -

243

243 -

244

244 -

245

245 -

246

246 -

247

247 -

248

248 -

249

249 -

250

250 -

251

251 -

252

252 -

253

253 -

254

254 -

255

255 -

256

256 -

257

257 -

258

258 -

259

259 -

260

260 -

261

261 -

262

262 -

263

263 -

264

264 -

265

265 -

266

266 -

267

267 -

268

268 -

269

269 -

270

270 -

271

271 -

272

272 -

273

273 -

274

274 -

275

275 -

276

276 -

277

277 -

278

278 -

279

279 -

280

280 -

281

281 -

282

282 -

283

283 -

284

284 -

285

285 -

286

286 -

287

287 -

288

288 -

289

289 -

290

290 -

291

291 -

292

292 -

293

293 -

294

294 -

295

295 -

296

296 -

297

297 -

298

298 -

299

299 -

300

300 -

301

301 -

302

302 -

303

303 -

304

304 -

305

305 -

306

306 -

307

307 -

308

308 -

309

309 -

310

310 -

311

311 -

312

312 -

313

313 -

314

314 -

315

315 -

316

316 -

317

317 -

318

318 -

319

319 -

320

320 -

321

321 -

322

322 -

323

323 -

324

324 -

325

325 -

326

326 -

327

327 -

328

328 -

329

329 -

330

330 -

331

331 -

332

332 -

333

333 -

334

334 -

335

335 -

336

336 -

337

337 -

338

338 -

339

339 -

340

340 -

341

341 -

342

342 -

343

343 -

344

344 -

345

345 -

346

346 -

347

347 -

348

348 -

349

349 -

350

350 -

351

351 -

352

352

|

|

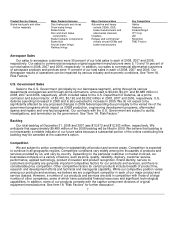

International Operations

We are engaged in manufacturing, sales, service and research and development mainly in the United States,

Europe, Canada, Asia and Latin America. U.S. exports and foreign manufactured products are significant to our

operations. U.S. exports comprised 10, 10 and 11 percent of our total sales in 2008, 2007 and 2006,

respectively. Foreign manufactured products and services, mainly in Europe, were 39, 39 and 37 percent of our

total sales in 2008, 2007 and 2006, respectively.

Approximately 19 percent of total 2008 sales of Aerospace-related products and services were exports of

U.S. manufactured products and systems and performance of services such as aircraft repair and overhaul.

Exports were principally made to Europe, Canada, Asia and Latin America. Foreign manufactured products and

systems and performance of services comprised approximately 14 percent of total 2008 Aerospace sales. The

principal manufacturing facilities outside the U.S. are in Europe, with less significant operations in Canada and

Asia.

Approximately 2 percent of total 2008 sales of Automation and Control Solutions products were exports of

U.S. manufactured products. Foreign manufactured products and performance of services accounted for 57

percent of total 2008 Automation and Control Solutions sales. The principal manufacturing facilities outside the

U.S. are in Europe with less significant operations in Asia and Canada.

Approximately 14 percent of total 2008 sales of Specialty Materials products and services were exports of

U.S. manufactured products. Exports were principally made to Asia and Latin America. Foreign manufactured

products and performance of services comprised 24 percent of total 2008 Specialty Materials sales. The principal

manufacturing facilities outside the U.S. are in Europe, with less significant operations in Asia and Canada.

Exports of U.S. manufactured products comprised 1 percent of total 2008 sales of Transportation Systems

products. Foreign manufactured products accounted for 71 percent of total 2008 sales of Transportation

Systems. The principal manufacturing facilities outside the U.S. are in Europe, with less significant operations in

Asia and Latin America.

Financial information including net sales and long-lived assets related to geographic areas is included in

Note 24 of Notes to Financial Statements in "Item 8. Financial Statements and Supplementary Data". Information

regarding the economic, political, regulatory and other risks associated with international operations is included in

"Item 1A. Risk Factors."

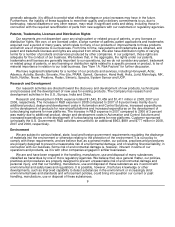

Raw Materials

The principal raw materials used in our operations are generally readily available. We experienced no

significant problems in the purchase of key raw materials and commodities in 2008. We are not dependent on

any one supplier for a material amount of our raw materials, except related to phenol, a raw material used in our

Specialty Materials segment. We purchase phenol under a supply agreement with one supplier. We have no

reason to believe there is any material risk to this supply.

The costs of certain key raw materials, including natural gas, benzene (the key component in phenol),

ethylene, fluorspar and sulfur in our Specialty Materials business, steel, nickel, other metals and ethylene glycol

in our Transportation Systems business, and nickel, titanium and other metals in our Aerospace business, are

expected to remain volatile. In addition, in 2008 certain large long-term fixed supplier price agreements expired,

primarily relating to components used by our Aerospace business, which in the aggregate, subjected us to higher

volatility in certain component costs. We will continue to attempt to offset raw material cost increases with formula

or long-term supply agreements, price increases and hedging activities where feasible. We have no reason to

believe a shortage of raw materials will cause any material adverse impact during 2009. See "Item 1A. Risk

Factors" for further discussion.

We are highly dependent on our suppliers and subcontractors in order to meet commitments to our

customers. In addition, many major components and product equipment items are procured or subcontracted on

a single-source basis with a number of domestic and foreign companies. We maintain a qualification and

performance surveillance process to control risk associated with such reliance on third parties. While we believe

that sources of supply for raw materials and components are

8