Audi 2007 Annual Report Download - page 83

Download and view the complete annual report

Please find page 83 of the 2007 Audi annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

A steady drive for perfection: Audi’s

successful production system

Frank Dreves,

Member of the Board

for Production of

AUDI AG

What is it that makes car manufacturing sustainable?

It’s impossible to identify just one aspect. Rather, it’s

about the complex interaction of several factors. The

crucial goal is to manufacture and offer the customer

an attractive, premium-quality product at a competitive

price. This requires not only an attractive product de-

sign and superior features, but also optimal utilization

of the available manufacturing capabilities and the

establishment of efficient, supported manufacturing

methods, based on clear standards.

With the new A4, we have successfully implemented

the “turntable concept” between Ingolstadt and

Neckarsulm. This means that, for the first time, we can

completely produce a high-volume model at two loca-

tions, from the sheet metal deep-drawing stage right

through to filling up the tank for the first time. This

allows for a flexible response to changes in demand.

The integration of the Brussels plant into Audi’s pro-

duction network is another important step toward

achieving our strategic objectives. It provides us with

additional capacity and more flexibility in the produc-

tion of the A segment. In 2008, 84,000 vehicles will roll

off the production line at our fourth European site.

The small, compact Audi A1 will also be manufactured

exclusively at the Brussels plant, which could amount

to a production volume of as many as 100,000 units

per annum.

The Audi Production System is vitally important for

perfection – in terms of both quality and productivity.

To ensure a better response to growing requirements in

terms of ergonomics, productivity and flexibility, we

have systematically enhanced our Audi Production Sys-

tem. The key principles have been and remain consis-

tently making production processes worker-friendly

and clearly focusing on minimizing throughput time.

This allows us to establish clear standards as a basis

for developing a synchronized company that’s focused

on value creation. I firmly believe that when it comes to

expanding our product range, standardization is crucial

for success. This applies to processes and production

equipment, but also to the products themselves. Prod-

uct standards help us to develop our cars in such a way

that our colleagues on the lines can assemble them ef-

ficiently. They also help us to deal with the increasing

complexity caused by derivatization, and to meet our

customers’ demands for a varied product range while

maintaining premium quality.

result: Kerosene savings of up to three percent are possible –

which corresponds to 2.5 tonnes on a long-distance flight.

Spiders’ webs are a great example of the efficiency pres-

ent in evolution. Finer than human hair and stronger than steel

filaments, they are also more elastic than rubber. This is the

only way a spider’s web can withstand the impact of a beetle

in full flight, for example. This makes spider’s silk far superior

to any synthetic fiber such as nylon or kevlar. Its strength is

due to the long protein chains which the spider produces in

order to hold the web firm. Only recently have scientists man-

aged to create genetically engineered spider silk. The potential

of this high-performance material is limitless. Fireproof cloth-

ing is one possibility, as are bullet-proof vests. Hopes for the

medical field include extremely fine suture material for oph-

thalmic or neurological surgery, artificial tendons and replace-

ments for bandages, band-aid and casts.

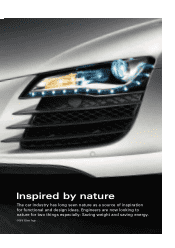

At Audi, lessons learned from nature are not just applied

to the vehicles themselves – but also to the whole production

process. “We think in terms of improved functionality at our

plants and production facilities, but also in terms of workflow

organization,” says Koglin. Already in use are grips, clamps,

manipulators and tactile sensors able to detect the presence of

components. Vacuum grippers, for example, work on the

gecko principle. These lizards have billions of tiny hairs on the

soles of their feet, which gives them such perfect grip that they

can even walk hanging down vertically from flat surfaces.

The larger the animal, the finer the hair structure. The best

thing is that this adhesion can be loosened easily and without

leaving a trace, something that makes it extremely interesting

for industrial use. Gecko gloves could be useful for moun-

taineers or window cleaners. Researchers are also busy work-

ing on “gecko tape,” which should provide excellent adhesion.

Penguins and bats, geckos and spiders, bamboo and water

lilies – we are far from having discovered all the potential

Mother Earth has to offer. “Nature is like a magic fountain,”

says American biologist Edward Osborne Wilson, who last

taught at Harvard and was presented with the U.S.’s highest

scientific award. “The more we draw from the reservoir of

knowledge and opportunities that Nature has given us, the

deeper it becomes.”

Industry is certainly not the only area to benefit from bionic

research. It will also benefit the environment, since many

of the innovative solutions from the hi-tech laboratory that is

nature embody the principle of sustainability: After all, the

only solutions that have survived during the course of evolu-

tion are those that require minimal utilization of energy

and materials. •

Klaus Jopp, chemist and author, writes for Financial Times Deutschland,

WirtschaftsWoche, Stern and Bild der Wissenschaft.

Photos: digital vision/gettyimages, Bill Curtsinger/gettyimages, Massimo Fiorito/chipimages, recaro pr, fototo/blickwinkel, AUDI AG (3)

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////