Boeing 2014 Annual Report Download - page 22

Download and view the complete annual report

Please find page 22 of the 2014 Boeing annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.10

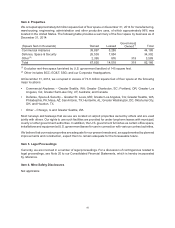

estimating costs and revenues on fixed-price contracts inherently risky. Fixed-price contracts often contain

price incentives and penalties tied to performance which can be difficult to estimate and have significant

impacts on margins. In addition, some of our contracts have specific provisions relating to cost, schedule

and performance.

Fixed-price development contracts are generally subject to more uncertainty than fixed-price production

contracts. Many of these development programs have highly complex designs. In addition, technical or

quality issues that arise during development could lead to schedule delays and higher costs to complete,

which could result in a material charge or otherwise adversely affect our financial condition. Examples of

significant BDS fixed-price development contracts include AEW&C, Commercial Crew, India P-8I, Saudi

F-15, USAF KC-46A Tanker, and commercial and military satellites.

We enter into cost-type contracts which also carry risks.

Our BDS business generated approximately 29% of its 2014 revenues from cost-type contracting

arrangements. Some of these are development programs that have complex design and technical

challenges. These cost-type programs typically have award or incentive fees that are subject to uncertainty

and may be earned over extended periods. In these cases the associated financial risks are primarily in

reduced fees, lower profit rates or program cancellation if cost, schedule or technical performance issues

arise. Programs whose contracts are primarily cost-type include GMD, Proprietary and SLS programs.

We enter into contracts that include in-orbit incentive payments that subject us to risks.

Contracts in the commercial satellite industry and certain government satellite contracts include in-orbit

incentive payments. These in-orbit payments may be paid over time after final satellite acceptance or paid

in full prior to final satellite acceptance. In both cases, the in-orbit incentive payment is at risk if the satellite

does not perform to specifications for up to 15 years after acceptance. The net present value of in-orbit

incentive fees we ultimately expect to realize is recognized as revenue in the construction period. If the

satellite fails to meet contractual performance criteria, customers will not be obligated to continue making

in-orbit payments and/or we may be required to provide refunds to the customer and incur significant

charges.

Our ability to deliver products and services that satisfy customer requirements is heavily dependent

on the performance of our subcontractors and suppliers, as well as on the availability of raw

materials and other components.

We rely on other companies including subcontractors and suppliers to provide and produce raw materials,

integrated components and sub-assemblies, and production commodities and to perform some of the

services that we provide to our customers. If one or more of our suppliers or subcontractors experiences

delivery delays or other performance problems, we may be unable to meet commitments to our customers

or incur additional costs. In addition, if one or more of the raw materials on which we depend (such as

aluminum, titanium or composites) becomes unavailable or is available only at very high prices, we may

be unable to deliver one or more of our products in a timely fashion or at budgeted costs. In some instances,

we depend upon a single source of supply. Any service disruption from one of these suppliers, either due

to circumstances beyond the supplier’s control, such as geo-political developments, or as a result of

performance problems or financial difficulties, could have a material adverse effect on our ability to meet

commitments to our customers or increase our operating costs. For example, we are monitoring political

unrest involving Russia and Ukraine, where we and some of our suppliers source titanium products and/

or have operations.