HTC 2014 Annual Report Download - page 79

Download and view the complete annual report

Please find page 79 of the 2014 HTC annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

• Affiliate information and other special notes Affiliate information and other special notes •

154 155

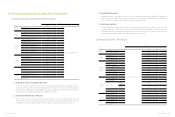

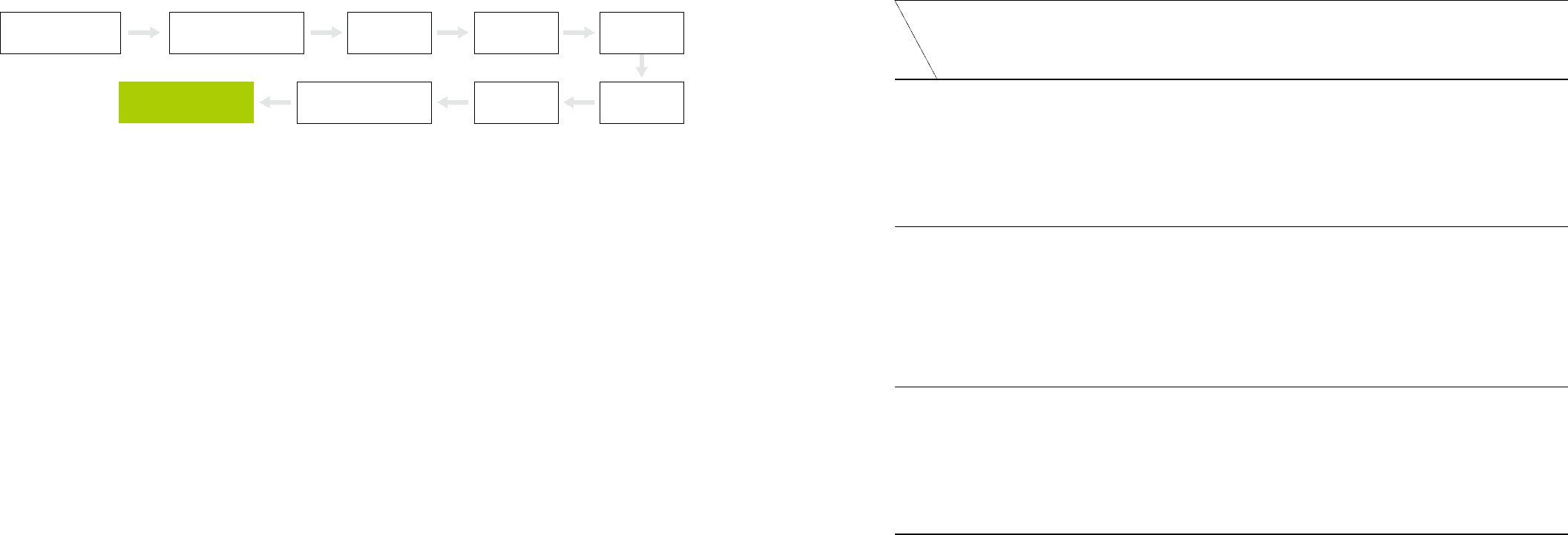

The workflow for handheld devices, from R&D through production, is as follows:

(2) Environmental Protection Expenditures

HTC primarily manufactures smartphones. With regard to production processes, airborne pollutants are generated only

during soldering and solid wastes at various production stages. HTC's production processes do not generate wastewater.

HTC places a high priority on effectively managing wastes generated by operations and consistently allocates significant

funds to install and maintain pollution prevention facilities and retain professional staff. HTC provides offsite training

for staff to acquire licenses needed to operate pollution control equipment. HTC further implements internal training

programs and conducts audits to ensure relevant pollution control mechanisms operate properly and effectively. HTC

regularly contracts independent licensed inspectors to review its operational environment. Audit and inspections of

HTC facilities conducted since HTC was founded confirmed that company operations comply with relevant government

rules and regulations.

HTC is certified OHSAS18001:2007 occupational health and safety management system, ISO 14001:2004 environmental

management, ISO 14064-1:2006 greenhouse gas emission standards and ISO50001:2011 energy management standard.

Certification-mandated procedures and requirements further reduce HTC pollution emissions and energy consumption

and move us forward toward clean production objectives.

1. Losses (including financial compensation) and fines due to pollution incidents

from the start of the most recent fiscal year and as of the date of this annual

report:

HTC has not been fined or penalized for pollution by environmental authorities.

2. Future strategies (inclusive of environmental protection facility improvements)

and possible expenditures:

a. Continue to strengthen the operations management on environmental protection equipment in order to comply

with government rules and regulations and reduce accidents and abnormalities;

b. In addition to regular management of disposables, our policy for reduction of these disposables is carried out

through categorization and education in order to reduce production of the disposables from their source.

Meanwhile, reusability received priority in consideration and further categorization on the rear end is added to

increase the reusability of recycled resources.

c. Continue promoting ISO 14001 environmental management, ISO 14064-1 technical and administrative measures

and ISO50001 energy management standard to maximize clean production benefits.

d. Major planned environmental expenditures over the next 2 years include:

Setting Product

Specifications

System

Assembly

Finished Product enters

warehouse

Software/

Hardware R&D

Finished Product Testing

& Inspection

Testing Certification Substrate

Manufacturing

Substrate

Testing

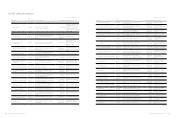

Unit:NT$ thousands

Fiscal

Year

Item Anticipated Equipment Purchases / Expenditures Anticipated Benefits

Expenditures

(estimated)

2015

1. Energy efficient lighting system

2. Pantry, washroom, and bathroom efficient water saving utilities

3. Inverters for elevators & air compressors

4. Water / power conservation promotion activities

5. Energy efficient air conditioning equipment

6. System to supply recycled wastewater

7. Rainwater collection tank construction to recycle rainwater

1. Reduce energy consumption by using LED lighting system

2. Pantry, washroom, and bathroom efficient water saving utilities

3. Reduce energy consumption through the inverters for elevators

& air compressors

4. Conserve water resources

5. Energy efficient air conditioning equipment

6. Conserve water resources

7. Conserve water resources by recycling rainwater for toilet flush

water

80,743

2016

1. Energy efficient lighting system

2. Water conservation facilities

3. Energy efficient air conditioning equipment

4. Inverters for elevators & air compressors

5. Waste water reprocess to provide for campus watering system and

ecological pond

6. Water / power conservation promotion activities

7. Garbage reduction and recycling promotion activities

8. Campus greening efforts

1. Reduce energy consumption by using LED lighting system

2. Pantry, washroom, and bathroom efficient water saving utilities

3. Energy efficient air conditioning equipment

4. Reduce energy consumption through the inverters for elevators &

air compressors

5. Promote general waste reduction & recycling

6. Conserve water resources

7. Reduce waste volumes by promoting garbage reduction and

recycling

8. Reduce energy consumption through campus greenification

105,450

2017

1. Energy efficient lighting system

2. Energy efficient air conditioning equipment

3. Inverters for air compressors

4. Waste water reprocess to provide for campus watering system

5. Water / power conservation promotion activities

6. Garbage reduction and recycling promotion activities

7. Campus greening efforts

1. Reduce energy consumption by using LED lighting system

2. Energy efficient air conditioning equipment

3. Reduce energy consumption through the inverters for air

compressors

4. Promote general waste reduction & recycling

5. Conserve water resources

6. Reduce waste volumes by promoting garbage reduction and

recycling

7. Reduce energy consumption through campus greenification

90,655

3. Environmental Protection and Employee Health & Safety Measures

Environmental Protection:

HTC is committed to operating healthy and safe work environments. HTC adheres to all local environmental protection

regulations. Cardboard boxes, containers and plastic packaging material are collected and separated for recycling. HTC

requires suppliers to comply with EU WEEE and RoHS environmental requirements in order to reduce industrial waste,

prevent pollution, and offer consumers products that reflect HTC's low environmental impact commitment.

Through green purchases followed by acquisition of raw materials or energy-efficient equipment, savings on use of

energy and resources, as well as decrease in pollution on the environment, are made possible for fulfilling duties, such as

reducing volume of the disposables, reusing recycled materials, and reducing the volume of carbon, for protection of the

environment.

HTC is committed to environmental responsibility and monitors its greenhouse gas sources and emissions in compliance

with ISO 14064-1 standards. HTC also follows ISO 50001 energy management standards to promote effective energy

management, and to achieve long-run sustainability and competitiveness.

Associated procedures include: