JVC 2003 Annual Report Download - page 26

Download and view the complete annual report

Please find page 26 of the 2003 JVC annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Victor Company of Japan, Limited

24 Annual Report 2003

Components & Devices

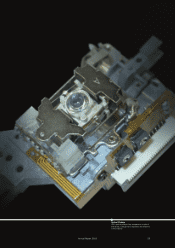

HDD Motors

Ultra-high precision bearings and assembly

technology result in low noise, long-life, shock

resistant HDDs

M-VIL High-density Build-up Multilayer PWBs

JVC’s advanced manufacturing techniques have not

only helped to increase the density and reduce the

size of volume production PWBs, they have also led

to enhancements in semiconductor and component

mounting quality

Deflection Yokes

JVC’s deflection yokes are ideal for high-resolution

CRTs such as PC monitors, thanks to their high-

speed scanning capabilities and environmentally

safe design

Tetsuo Kashiwagi

President, Components & Device Company

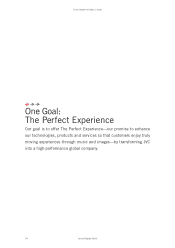

The development, manufacture and sale of electronic components and devices accounts for 5% of JVC’s total sales. The

segment reported another loss in fiscal 2003 as the extended downturn in the IT industry and the cost of restructuring

measures to build a profitable operating base held back performance. With the benefits of these actions now showing

through, this segment is on the path back to profitability.

paring back fixed costs to make this

segment more competitive. Although

LCD technology is rapidly becoming the

de facto standard in the PC monitor

market, demand for high-resolution

CRTs is certain to remain for some

time. By rigorously controlling ex-

penses, we are determined to remain a

leading supplier of deflection yokes as

market contraction leaves only a few

surviving manufacturers. We expect

substantial growth in high-density

build-up multilayer printed wiring

boards. Originally used mainly in mo-

bile phones, these boards are now

found in digital still cameras (DSCs)

and digital video cameras (DVCs). We

are confident that through the above

steps, we have established a profit

structure that will benefit directly from

closing unprofitable operations and in-

vesting in key device categories to be-

come ultimately more cost competitive.

Investment in Next-Generation Key

Devices

Opto-electronics components for Blu-

ray Disc equipment is an attractive

new field for JVC. With exclusive tech-

nology for optical pickups, we are in

an excellent position to develop “Only

Specializing in the Development and

Manufacture of Key Devices

Until recently, this segment mainly

manufactured products for external

customers. Although these activities

remain important, from now on the

segment will almost exclusively sup-

ply key devices needed to create dis-

tinctive, value-added JVC products.

JVC will sell these devices to other

companies when they become ac-

cepted as the industry standard. We

decided to cease manufacturing and

selling components where we don’t

have a competitive edge. This included

withdrawing from the magnetic head

and crystal quartz device businesses.

What remains is a portfolio of profit-

able and competitive products that

includes deflection yokes for high-

resolution computer monitors, high-

density build-up multilayer printed

wiring boards, motors for optical and

hard disk drives, and optical pickups.

Poised for a Return to Profitability in

the Current Fiscal Year

We are currently making our key device

business more cost-competitive. In de-

flection yokes, for instance, we are re-

aligning manufacturing bases and

One” products in this field. Sales to

external customers could become a

major earnings source going forward.

Another new technology poised to cre-

ate future “Only One” products is the

fluid dynamic bearings of our HDD mo-

tors, produced using an exclusive and

trusted JVC technique. We are now

investing in additional production ca-

pacity to begin full-scale motor pro-

duction in the following fiscal year. At

this early stage, investing in these key

devices has yielded no immediate re-

turns. We are confident though that

this investment will translate into sub-

stantial earnings as the segment’s key

devices play a growing role in JVC’s

new products.