JVC 2003 Annual Report Download - page 11

Download and view the complete annual report

Please find page 11 of the 2003 JVC annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Victor Company of Japan, Limited

Annual Report 2003 9

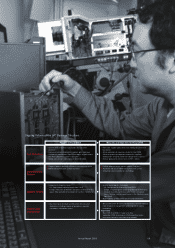

Ongoing Reform of the JVC Business Structure

Cost Reduction

Manufacturing

Reform

Logistics Reform

Supply Chain

Management

Progress in Fiscal 2003 Measures and Objectives for Fiscal 2004

•Centralization of purchasing functions for consumer

electronics

•Reducing number of domestic suppliers gets underway

•Component procurement from China begins; establishment

of a Parts Laboratory Center in Shanghai

•Global procurement costs reduced to ¥44.6 billion

•Progress towards realizing a 6-month manufacturing cycle

•Mother base production system launched

•Realignment of logistics bases

· US: Steps toward reducing bases from 5 to 3

· Europe: Reduction of Northern European bases from 3 to 1

· Japan: New operational framework for facility in Yokohama

•Initial steps taken to create a SCM system for consumer

electronics including creation of guidelines; specialist

framework; information system

•Formulate supplier policy to ensure stable procurement of

key devices

•Active promotion of measures started in fiscal 2003

(Value engineering/integration of domestic suppliers/

development and procurement of components in China)

•Reduce global procurement costs to ¥37.1 billion

•Further advance design process reform (2nd year)

•Accelerate roll out of mother base production system

•Strengthen volume production technology

•Realize leaner logistics framework

·US: Realignment to 3 bases by fiscal 2005

·Europe: Integrate logistic bases for professional electronics;

integrate inventory warehousing for 3 sales companies

·Japan: Reduce inventory warehouses in the Yokohama area

from 9 to 3

•Begin logistics system reform for consumer electronics

•Bring SCM system for consumer electronics online/introduce

more responsive management system based on weekly

timetabling

Target dates

May 2003: 4 factories in Japan and Asia

September 2003: 6 factories in US/Europe/Asia (entire

consumer electronics manufacturing network)

Annual Report 2003 09