Nissan 2013 Annual Report Download - page 44

Download and view the complete annual report

Please find page 44 of the 2013 Nissan annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Nissan has promoted countermeasures based on three basic principles

stated in the global policy, which are:

1. First priority on employees’ health and lives

2. Prevention of the spread of infection

3. Continuity of business operation

As specific actions, Nissan established the “guidelines for employees’

action” which stipulated actions to be taken by employees, Sections and

Companies, and kept employees informed.

Nissan also developed a Business Continuity Plan (BCP) for each

business section, with several triggers to invoke the BCP depending on

the infection ratio, to maintain business continuity even under a high

infection situation.

Nissan will keep prepared for contingencies like avian flu through its

PDCA cycle, such as by updating response team members and the BCP,

carrying out educational activities for infection prevention and stockpiling

sanitary and medical goods.

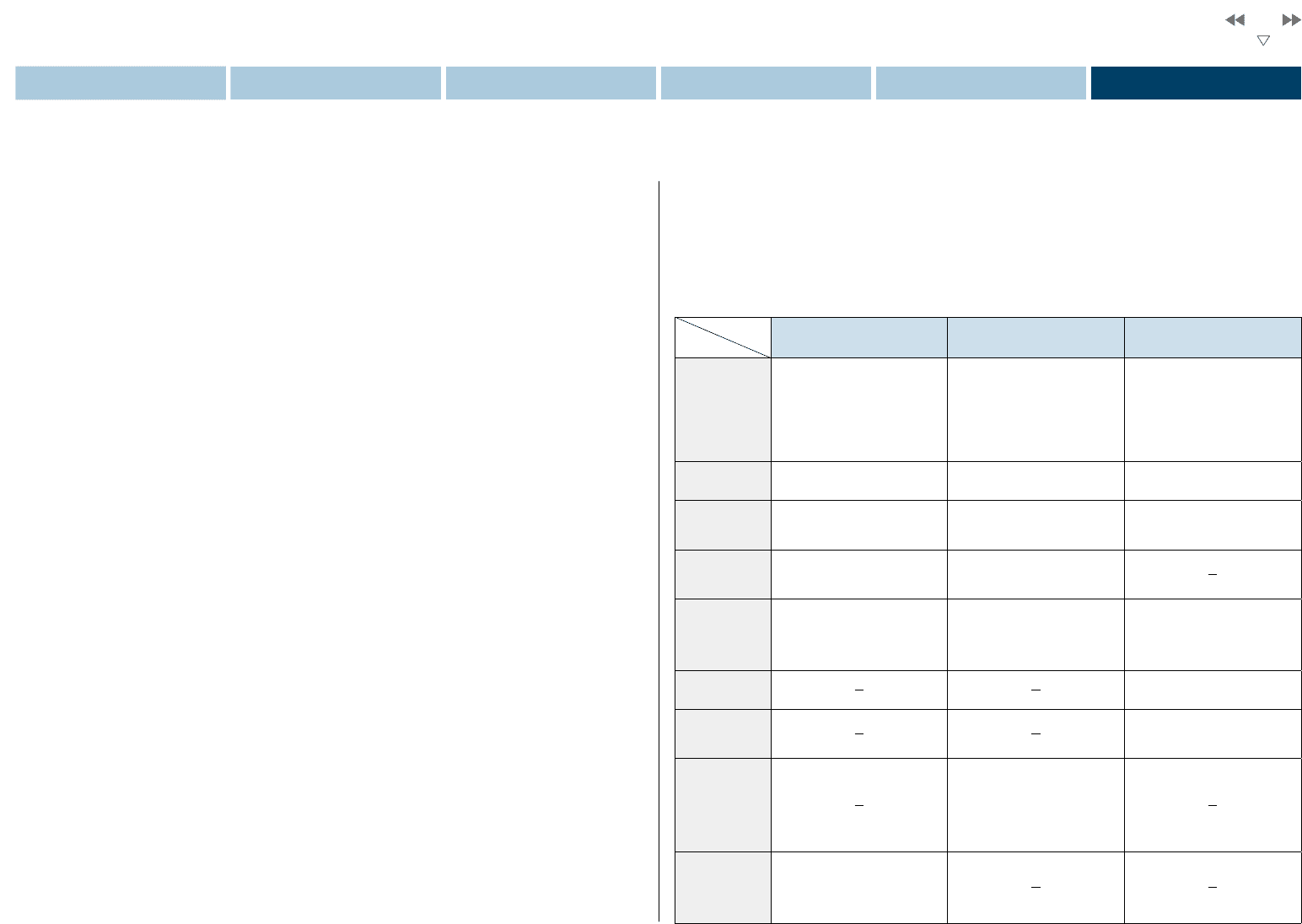

3) Countermeasures for Production Continuity Risk

Nissan’s production division has dealt with various risks related to the three

elements of production, as listed in the chart at right. Particularly for natural

disasters, we have identified the measures needed to restart production within

our established goal of two weeks following a large-scale disaster. We have

worked over the years on continuous prevention countermeasures to physical

infrastructure (quakeproofing and reinforcement of buildings and other

facilities), maintained an operations recovery manual to shorten recovery time

and regularly executed BCP simulation drills. We are also strengthening the

resilience of our global production network by establishing a BCP for parts

exports to enable continued operations at our overseas plants.

In addition to such countermeasures to natural disasters, it is absolutely

important to manage risks associated with parts procured from Leading

Competitive Countries (LCCs) in order to expand markets globally. To deal

with such risk, Nissan has been conducting risk assessment before making

sourcing decisions, providing support for improvement activities after

sourcing, implementing quality checks at key points in the production and

logistics process to prevent the production and utilization of imperfect parts

and undertaking activities to confirm and help improve supply capacity in

order to secure global market expansion and growth. Specifically, in addition

to existing organizations to manage supplier risk in North America, Europe

and Japan, new bodies are being created in Thailand, China and India to

reinforce our global efforts to prevent risks associated with the supplies of

parts.

HR/Workforce Purchased parts/

Raw materials Facilities

Risk factor

Natural disasters

(earthquakes)

l Reinforcement of office buildings (completed)

l Development of earthquake response manual,

implementation of evacuation drills (once/year)

l Conducting of disaster prevention drills (once/year

or more)

l Assessment of earthquake preparedness of major

suppliers located in high quake-risk areas (FY08)

l Planning to adopt damage reporting system on web

base (FY10)

l Confirmation of BCPs to be implemented at time of

disaster by suppliers in high quake-risk areas

(FY11)

l BCP for parts exports to continue production at

overseas plants (FY12)

l Reinforcement of buildings & machinery

(continued)

l Regular audits of each business facility

l Review of facility recovery manual (FY11)

Fire l Risk assessment based on F-PES (Fire Prevention

Evaluation System) (once/year)

l Same as on the left l Same as on the left

l Revision of equipment standard based on the

assessment result

Workplace injury l Risk assessment based on SES (Safety Evaluation

System) (once/year)

l Assessment for health & safety management

system (once/year)

l Same as on the left l Same as on the left

Pandemic l Development of flu response manual (FY09) l Requested suppliers to develop response manual

coordinated with Nissan

Demand fluctuation l Backup from other Nissan plants (as needed)

l Backup from other companies (as needed)

l Employment of short-term employees (as needed)

Regular check of demand projection and supply

capacity; implementation of measures

l Installation of flexible manufacturing system

(completed)

l Regular check of demand projection and production

capacity; implementation of measures

l Development of complementary production system

for main powertrains

Machinery breakdown l Share past incident experiences and reflect them in

preventive maintenance

l Reflect them in equipment standards

Electric power shortage l Thoroughgoing energy conservation efforts

l Flexibility in plant operations and working hours in

response to requests from the government or

power companies

Expansion of LCC-

manufactured parts

l Assessment of monozukuri ability before supplier

sourcing and support for improvement activities

after sourcing

l Quality assessment at production preparation phase

l Quality check at mass production phase (action

“Gate 1-3”)

l Establishment of organization for supplier risk

management at operations in major LCCs (FY12)

Decrease of skilled

workers/experts

l Planning and implementation of training program at

each plant to develop skilled workers (FY10)

l Global development of human resources through the

Global Pilot Plant program (FY11)

l Development of experts to teach technical skills

(planning and implementation from FY12)

3 elements of

production

43

CORPORATE GOVERNANCE

NISSAN MOTOR COMPANY ANNUAL REPORT 2013

CONTENTS

MANAGEMENT MESSAGES

CORPORATE FACE TIME

PERFORMANCE

NISSAN POWER 88