Konica Minolta 2008 Annual Report Download - page 5

Download and view the complete annual report

Please find page 5 of the 2008 Konica Minolta annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

3

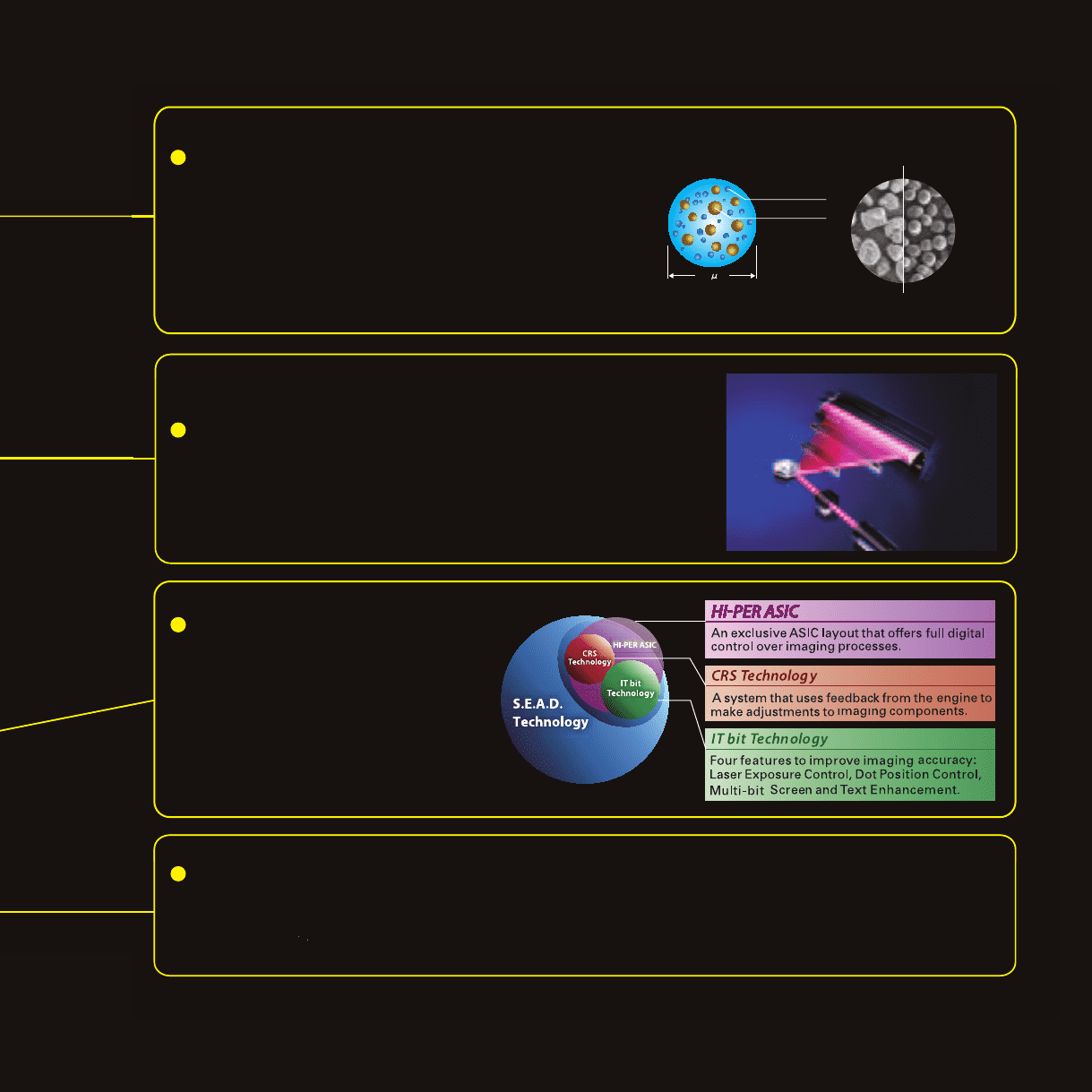

High-Accuracy Laser Exposure Controller

We created a fully digital laser-driven pulse-width modulator that ensures

high precision and fast output by controlling nanosecond laser unit pulses

to deliver swift and stable four-color pixel writing.

Post-Processing System for Print-on-Demand Applications

We have drawn on paper processing expertise from years in the production printing business to create numerous

post-processing technologies, notably for saddle and side stitching, folding, hole punching, and booklet finishing.

We are an industry—leading supplier of online post-processing systems.

Hig

h

-Accuracy Laser Ex

p

osure Contro

ll

e

r

created a fully digital laser-driven

p

ulse-width modulator that ensures

W

e

h

p

recision an

d

fast out

p

ut

b

y contro

ll

ing nanosecon

d

l

aser unit

p

u

l

ses

gh

h

i

g

d

e

l

iver swift an

d

sta

bl

e four-co

l

or

p

ixe

l

writing

.

d

to

d

Post-Processing System for Print-on-Deman

d

A

p

pl

ications

h

ave

d

rawn on

p

a

p

er

p

rocessing ex

p

ertise from years in t

h

e

p

ro

d

uction

p

rinting

b

usiness to create numerous We

s

t-processing tec

h

no

l

ogies, nota

bl

y for sa

ddl

e an

d

si

d

e stitc

h

ing, fo

ld

ing,

h

o

l

e punc

h

ing, an

d

b

oo

kl

et finis

h

ing.

p

o

s

are an

in

du

str

W

e

y

r

r

—

y

y

l

ea

d

ing supp

l

ier of on

l

ine post-processing systems.

Proprietary S.E.A.D. Technology

Our Screen-Enhancing Active Digital

Processing (S.E.A.D.), incorporates an

application-specific integrated circuit to

provide micron-level image control and

optimally process images and text. S.E.A.D.

employs technology to stabilize high-speed

image quality, for results comparable to

those of offset printers.

Pulverized Toner Polymerized Toner

Color material

Composition of Polymerized Toner

Wax

1

2

3

4

P

roprietary S.E.A.D. Technolog

y

P

r

Screen-En

h

ancin

g

Active Di

g

ita

l

r

O

u

r

c

essing

(

S.E.A.D.

)

, incorporates an

oc

Pr

o

p

lication-specific integrated circuit to

p

app

ap

p

v

ide micron-level image control and

ov

p

r

o

i

mally

p

rocess images and text. S.E.A.D.

ti

opt

p

loys technology to stabilize high-s

p

eed

p

e

m

p

a

ge

q

uality, for results com

p

arable to

a

i

m

a

s

e of offset

p

rinters.

s

th

o

3

Polymerized Toner

Our polymerized toner features the industry’s finest and most

uniform particles to achieve highly defined image quality.

Since the toner enhances low-temperature fusing, it reduces

paper curls and buckling and increases paper-handling capability.

In addition, this toner reduces environmental load

comprehensively from production to end use.

High-Accuracy Laser Exposure Controller

Polygon mirror

Drum

Fθ Iens

Laser unit