Porsche 2005 Annual Report Download - page 93

Download and view the complete annual report

Please find page 93 of the 2005 Porsche annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

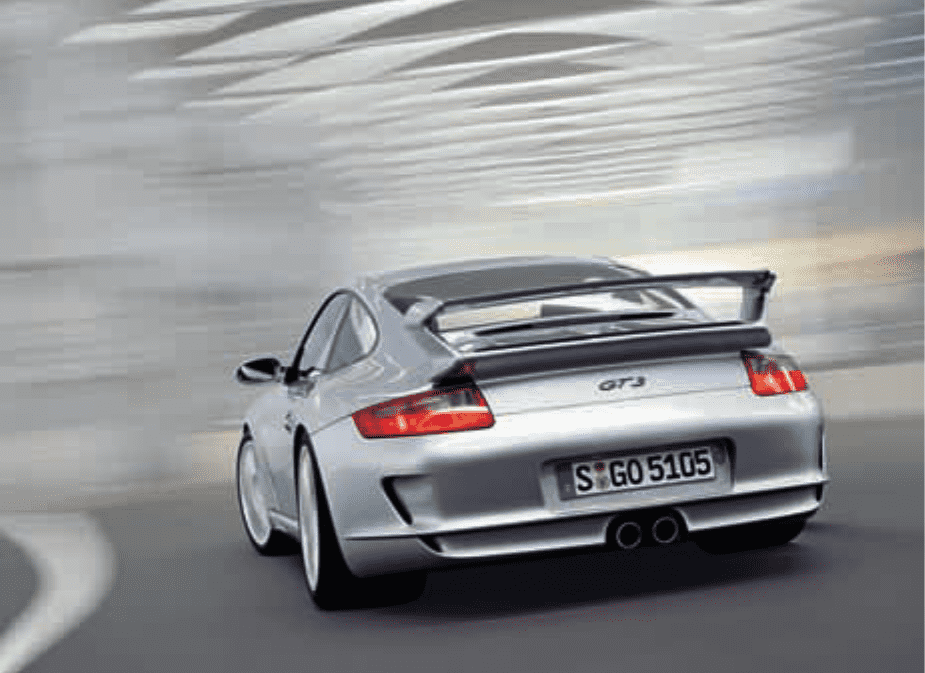

speed range. Acceleration from 80 to 120 km/h in the second

highest gear takes 3.5 seconds instead of 3.8 on manual trans-

mission versions, and 3.3 seconds instead of 3.5 with the Tip-

tronic S. This overboost is particularly ideal for intermediate

acceleration and can shorten overtaking maneuvers.

Optimum Power Distribution

The outstanding acceleration performance of the 911Turbo is

only possible if power transfer can be well-controlled at all times.

Consequently, the vehicle features new all-wheel drive techno-

logy, the Porsche Traction Management (PTM), as standard. It is

based on the experiences gained with the traction management

system on the Cayenne. Additional drive to the front wheels is

now provided actively by means of an electronically controlled,

electromagnetically-actuated multi-disk clutch. Power can there-

fore be distributed optimally even when there is no difference

in rotational speed.

Thanks to this new technology, power transfer can be optimally

adapted to the prevailing driving conditions, whilst fast re-

sponse times ensure that the front axle is engaged in less than

0.1 seconds. If required, and in certain driving situations – such

as when the rear wheels are spinning on ice – all the power is

transferred to the front wheels.

The Porsche Traction Management’s control system is based

on a host of parameters which are evaluated in the PTM control

unit. These include engine torque, steer angle, wheel rotational

speed, lateral acceleration and vehicle dynamics signals such

as oversteer and understeer. These data are used to calculate

the optimum power distribution between the front and rear axle

and control the multi-disk clutch.

This complex and highly dynamic system ensures even better

agility and dynamic performance as well as maximum stability –

and consequently a high degree of active safety – at high

speeds. In practice, this means no more wheel spin, even on

wet roads, and the 911 Turbo always remains safely on course

even at maximum speeds. For customers with more sporty

ambitions, there’s the option of a mechanical rear axle lock.

It assists the PTM, by providing additional dynamic handling

ability and traction, increases lateral acceleration and improves

circuit performance.

To achieve this outstanding performance, however, a lightweight

design is essential. In the course of the development process,

therefore, each individual component was investigated for any

weight reduction potential. Consequently, many modifications to

design details were implemented. The main area of focus, how-

ever, was the vehicle body, where various lightweight components

have been used. The front lid, made from aluminum, now weighs

51 percent less. The composite fiber rear lid weighs just 4.5 kilo-

grams, 62 percent less than an equivalent steel version.

Lightweight construction is normally associated with higher costs.

To find an optimum solution to this conflict of aims, a develop-

ment project for an aluminum door was undertaken. As a result,

it has been possible to drastically reduce the number of compo-

nents. Compared with a steel shell, which has 15 panel compo-

nents, five bolt connections and 85 weld spots, the aluminum

shell has just five aluminum parts and ten bolt connections. This

simplified design, along with associated tool investment savings

and shorter production and assembly times, have reduced costs

considerably. Weight reduction per vehicle is around 14.4 kilo-

grams compared with a steel shell. The new structure also has