Xcel Energy 2015 Annual Report Download - page 6

Download and view the complete annual report

Please find page 6 of the 2015 Xcel Energy annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

6 XCEL ENERGY | Annual Report 2015

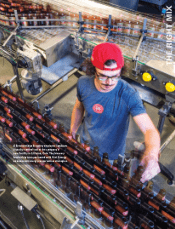

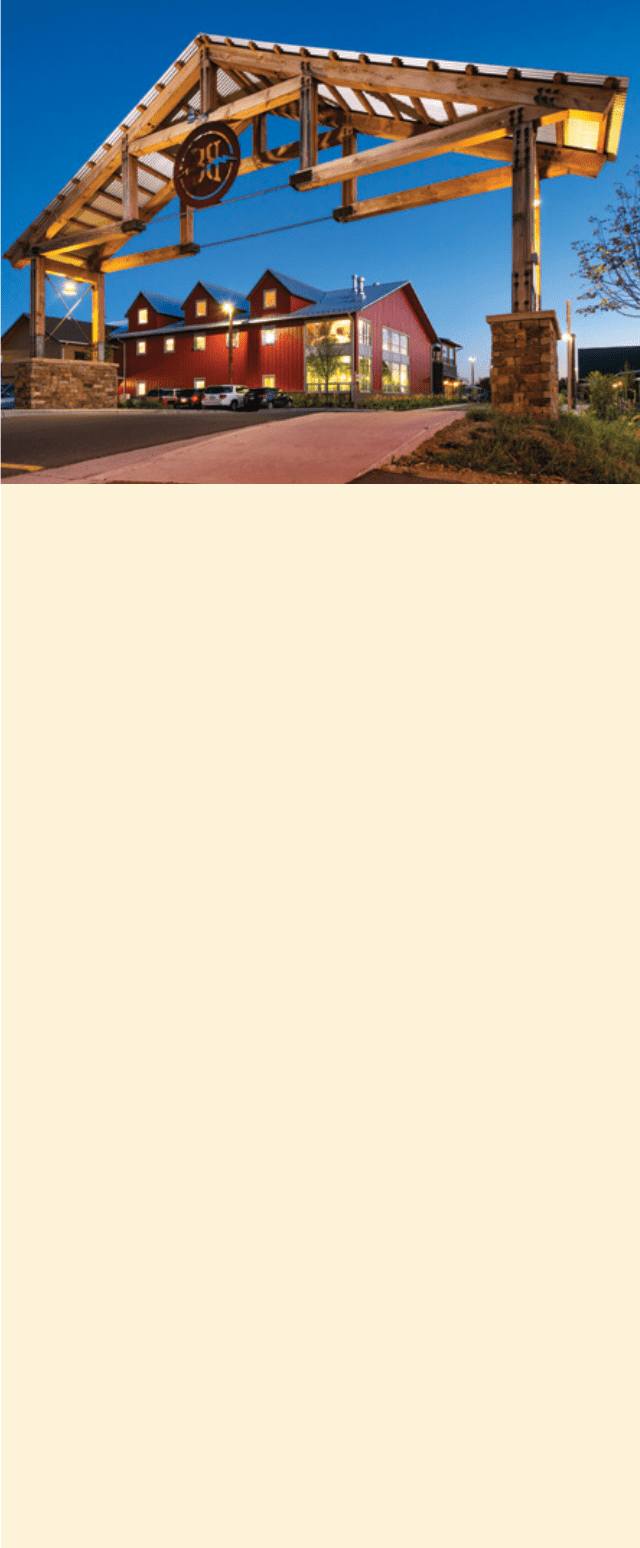

BRECKENRIDGE BREWERY: A PERFECT

BATCH OF ENERGY-EFFICIENT SOLUTIONS

When Breckenridge Brewery opened in 1990, it was the third

craft brewery in Colorado. Twenty ve years later, it has grown to

produce more than 70,000 barrels of beer annually, distributed in 35

states. When its growth plans called for a new brewery to be built in

Littleton, Colo., the leadership team partnered with our Energy Design

Assistance (EDA) program to design a rst class, energy-efcient

facility.

During the design and construction phase, Xcel Energy collaborated

with the brewery team, contractors and architects to develop and

incent efciency strategies ranging from choosing energy-efcient

building materials, sensors and lighting xtures throughout the facility

to recapturing heat from the brewing process. This tailored solution

encompassed both the building envelope and manufacturing process

to ensure energy efciency was achieved every step of the way.

The Breckenridge Brewery leadership team saw the value of

these plans and invested in these solutions at the new facility that

opened last summer. Those investments more than paid off. After

an independent consultant veried the energy savings, Xcel Energy

delivered an incentive check for $59,470. Even more importantly, the

brewery will save nearly $51,000 in energy costs annually, recapturing

its up-front investment in ve years and freeing valuable capital to

reinvest in the business.

“Who doesn’t like to get a $60,000 rebate check?” Breckenridge

Brewery President Todd Usry asked. “Xcel Energy and the third party

consultant were great to work with from the pre-construction phase

all the way through.”

In 2015, the EDA program rewarded Colorado and Minnesota

customers with more than $11.2 million in rebates for using energy-

efcient design in 136 buildings.

successful launch of a new general ledger at the close of

2015. This and additional system upgrades scheduled for

the next two years are key tools that will lead to increased

productivity and streamlined operations.

Employee and public safety is an important part of The

Right Mix needed to achieve operational excellence. It is

an Xcel Energy priority that every employee goes home

safe each night. I am pleased that we achieved the eighth

consecutive year of improved employee safety results, with

a reduction in both injury count and severity. According to

our annual engagement survey, 94 percent of our employees

indicate that their work area is a safe place and 91 percent

indicate that safety rules are carefully observed, even if it

means that work is slowed down.

We continue to cultivate a culture of safety to protect the

public—a responsibility we take very seriously. We have

replaced all known cast iron natural gas distribution lines,

initiated a project to move meters to the outside of older

homes and installed additional safety measures to better

protect above-ground natural gas equipment from potential

damage by vehicles.

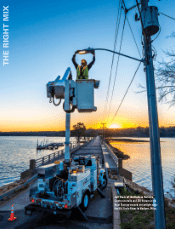

Our electrical system delivers reliable service more than

99 percent of the time on average, and prompt service

restoration is a hallmark of our business. When severe storms

in Texas and New Mexico disrupted power in December, our

dedicated employees once again delivered, safely restoring

power to 84 percent of customers within 12 hours and

98 percent of customers within 24 hours. We also received

the Edison Electric Institute’s Emergency Response Recovery

Award for our work during a July storm in Minnesota

that impacted 250,000 customers. We continue to make

improvements in our customer communication, allowing

customers to plan accordingly during service outages.

We also prepare for threats that we can’t see. Last fall,

more than 150 employees participated in the GridEx III, a

two-day national drill coordinated by the North American

Electric Reliability Corporation (NERC), to test the industry’s

preparedness for a national physical and cyber attack on the

electric grid. This exercise provided a meaningful opportunity

to evaluate our responsiveness and communications plans,

and to strengthen our connection to government response

agencies. We are investing in both assets and talent to make

the energy grid even more robust, resilient and secure.

Expand customer options and solutions

Our customers want more ways to save energy and money, to

connect with us in the ways convenient to them and exercise