Columbia Sportswear 2010 Annual Report Download - page 59

Download and view the complete annual report

Please find page 59 of the 2010 Columbia Sportswear annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

COLUMBIA SPORTSWEAR COMPANY

NOTES TO CONSOLIDATED FINANCIAL STATEMENTS—(Continued)

Country and supplier concentrations:

The Company’s products are produced by independent factories located outside the United States,

principally in Southeast Asia. Apparel is manufactured in more than 13 countries, with Vietnam and China

accounting for approximately 68% of 2010 global apparel production. Footwear is manufactured in three

countries, with China and Vietnam accounting for approximately 93% of 2010 global footwear production. The

five largest apparel factory groups accounted for approximately 20% of 2010 global apparel production, with the

largest factory group accounting for 7% of 2010 global apparel production. The five largest footwear factory

groups accounted for approximately 81% of 2010 global footwear production, with the largest factory group

accounting for 34% of 2010 global footwear production. In addition, a single vendor supplies substantially all of

the zippers used in our products. These companies, however, have multiple factory locations, many of which are

in different countries, thus reducing the risk that unfavorable conditions at a single factory or location will have a

material adverse effect on the Company.

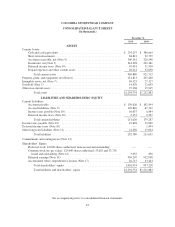

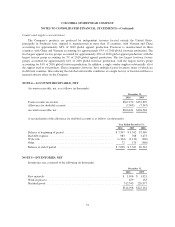

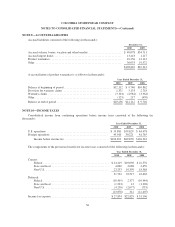

NOTE 4—ACCOUNTS RECEIVABLE, NET

Accounts receivable, net, is as follows (in thousands):

December 31,

2010 2009

Trade accounts receivable ........................................... $307,279 $233,895

Allowance for doubtful accounts ..................................... (7,098) (7,347)

Accounts receivable, net ............................................ $300,181 $226,548

A reconciliation of the allowance for doubtful accounts is as follows (in thousands):

Year Ended December 31,

2010 2009 2008

Balance at beginning of period .................................. $7,347 $ 9,542 $7,369

Bad debt expense ............................................. 983 768 3,473

Write offs ................................................... (1,304) (3,133) (940)

Other ...................................................... 72 170 (360)

Balance at end of period ....................................... $7,098 $ 7,347 $9,542

NOTE 5—INVENTORIES, NET

Inventories, net, consisted of the following (in thousands):

December 31,

2010 2009

Raw materials .................................................... $ 1,096 $ 1,021

Work in process ................................................... 659 163

Finished goods .................................................... 312,543 220,977

$314,298 $222,161

53