Motorola 2014 Annual Report Download - page 16

Download and view the complete annual report

Please find page 16 of the 2014 Motorola annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.14

Over the last several years we have outsourced portions of certain business operations like IT, HR information

systems, manufacturing, repair, distribution and engineering services and expect to outsource additional business

operations which limits our control over these business operations and exposes us to additional risk as a result of the

actions of our outsource partners.

As we outsource more of our business operations we are not able to directly control these activities. Our outsource

partners may not prioritize our business over that of their other customers and they may not meet our desired level of quality,

performance, service, cost reductions or other metrics. Failure to meet key performance indicators may result in our being in

default with our customers. In addition, we may rely on our outsource partners to secure materials from our suppliers with whom

our outsource partners may not have existing relationships and we may be required to continue to manage these relationships

even after we outsource certain business operations.

As we outsource business operations we become dependent on the IT systems of our outsource partners, including to

transmit demand and purchase orders to suppliers, which can result in a delay in order placement. In addition, in an effort to

reduce costs and limit their liabilities our outsource partners may not have robust systems or make commitments in as timely a

manner as we require.

In some cases the actions of our outsource partners may result in our being found to be in violation of laws or regulations

like import or export regulations. As many of our outsource partners operate outside of the U.S., our outsourcing activity

exposes us to information security vulnerabilities and increases our global risks. In addition, we are exposed to the financial

viability of our outsource partners. Once a business activity is outsourced we may be contractually prohibited from or may not

practically be able to bring such activity back within the Company or move it to another outsource partner. The actions of our

outsource partners could result in reputational damage to us and could negatively impact our financial results.

We utilize the services of subcontractors to perform under many of our contracts and the inability of our

subcontractors to perform in a timely and compliant manner could negatively impact our performance obligations as

the prime contractor.

We engage subcontractors, including third-party integrators on many of our contracts and as we expand our solutions and

services business our use of subcontractors has and will continue to increase. Our subcontractors may further subcontract

performance and may supply third-party products and software from a number of smaller companies. We may have disputes

with our subcontractors, including disputes regarding the quality and timeliness of work performed by the subcontractor or its

subcontractors and the functionality, warranty and indemnities of products, software and services supplied by our subcontractor.

We are not always successful in passing down customer requirements to our subcontractors, and thus in some cases may be

required to absorb contractual risks from our customers without corresponding back-to-back coverage from our subcontractor.

Our subcontractors may not be able to acquire or maintain the quality of the materials, components, subsystems and services

they supply, or secure preferred warranty and indemnity coverage from their suppliers which might result in greater product

returns, service problems, warranty claims and costs and regulatory compliance issues and could harm our business, financial

condition and results of operations.

Failure of our suppliers, subcontractors, distributors, resellers and representatives to use acceptable legal or ethical

business practices and adhere to our Supplier Code of Conduct or our Human Rights Policy could negatively impact

our business.

It is our policy to require our suppliers, subcontractors, distributors, resellers, and third-party sales representatives

(“TPSRs”) to operate in compliance with applicable laws, rules and regulations regarding working conditions, employment

practices, environmental compliance, anti-corruption and trademark and copyright licensing. However, we do not control their

labor and other business practices. If one of our suppliers, subcontractors, brokers, distributors, resellers, or TPSRs violates

labor or other laws or implements labor or other business practices that are regarded as unethical, the shipment of finished

products to us could be interrupted, orders could be canceled, relationships could be terminated and our reputation could be

damaged. If one of our suppliers or subcontractors fails to procure necessary license rights to trademarks, copyrights or patents,

legal action could be taken against us that could impact the salability of our products and expose us to financial obligations to a

third-party. Any of these events could have a negative impact on our sales and results of operations.

Our employees, customers, suppliers and outsource partners are located throughout the world and, as a result, we

face risks that other companies that are not global may not face.

Most of our products that are manufactured by us outside the U.S. are manufactured in Malaysia. If manufacturing in our

facility in Malaysia is disrupted, our overall capacity would be significantly reduced and sales or profitability could be negatively

impacted.

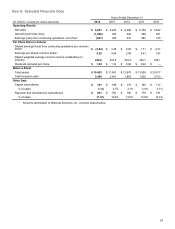

Our customers and suppliers are located throughout the world. In 2014, approximately 39 percent of our revenue was

generated outside the U.S. In addition, we have a number of research and development, administrative and sales facilities

outside the U.S. and more than 50% of our employees are employed outside the U.S. Most of our suppliers' operations are

outside the U.S. and most of our products are manufactured outside the U.S., both internally and by third-parties.

Because we have sizable sales and operations, including outsourcing and procurement arrangements, outside of the U.S.,

we have more complexity in our operations and are exposed to a unique set of global risks that could negatively impact sales or

profitability, including but not limited to: (i) currency fluctuations, (ii) import/export regulations, tariffs, trade barriers and trade

disputes, customs classifications and certifications, including but not limited to changes in classifications or errors or omissions

related to such classifications and certifications, (iii) changes in U.S. and non-U.S. rules related to trade, environmental, health