Porsche 2015 Annual Report Download - page 97

Download and view the complete annual report

Please find page 97 of the 2015 Porsche annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

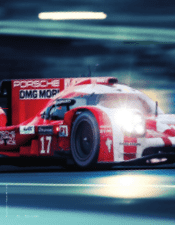

330 km/h, the turbine in the exhaust tract has to work very

hard. So far, so good. However, both energy sources are lim-

ited: the car is not allowed to use more than 4.65 litres of

petrol per lap and not more than 2.22 kilowatt-hours of elec-

trical energy.

Therefore the driver has to be frugal so that he has enough

fuel at the end of the round and not one drop has been con-

sumed more than permitted, and preferably not less either. It

is a balancing act: if he consumes more, he will pay for it later.

If he consumes less, he loses on performance. The trick is

tostop boosting electrical energy at exactly the right moment

as well as step off the accelerator at the right moment.

The 2.22 kilowatt-hours of electrical energy correspond to

eight megajoules – and that is the highest energy class

therules permit. Porsche was the first and only manufacturer

in 2015 to venture this far. Audi and Toyota were only able

todemonstrate four and six megajoules respectively. The

reason Porsche was confident enough to achieve this peak is

thanks to a bold and fundamental decision.

“The choice of concept was inspired by us looking at each of

the various alternatives in detail,” Hitzinger reflects. It was

immediately clear that we would use the braking energy from

the front axle. Engineers call this a “no-brainer” – large

energy gains on partially familiar terrain, coupled with major

further developments. “As the second system, the brake

energy recovery on the rear axle or the exhaust energy recov-

ery came into question.” Two aspects spoke in favour of the

exhaust solution. First, the weight and second, the efficiency.

“To recover braking energy, the system has to recuperate

theenergy in a very short time, so it has to handle a lot of

power, meaning more weight. However, the acceleration

phases are far longer than the braking phases, so the system

recovers for longer and that makes it lighter. “Besides”

Hitzinger adds, “we already have a drive on the rear axle with

the combustion engine. With even more power at the rear

wewould create more slippage. “Slippage is practically the

opposite of efficiency and also ruins the tyres.”

Probably the boldest fundamental decision: Hitzinger opted

for800 volts for the hybrid system of the 919. “Determining

the voltage level is a major decision for the electric drive,”

heemphasises; “it affects everything – battery design, elec-

tronics design, electric engine design, charging technology

and charging infrastructure. We went as far as it was possible

to go.” It was difficult to find parts for such a high voltage,

especially a suitable storage medium. Flywheel accumulator,

super capacitors or battery? Hitzinger decided on a liquid-

cooled lithium-ion battery. It has hundreds of single cells, each

enclosed in separate cylindrical metal capsules, seven centi-

metres high and 1.8 centimetres in diameter.

For a road-going model, as well as a race car, there needs

tobe a balance between power density and energy density.

Thehigher the power density of a cell, the faster it can be

charged and release energy again. The other parameter, the

energy density, determines the amount of energy that can

bestored. In racing, the cell must – figuratively speaking –

have a huge opening. Because as soon as the driver stamps

on the brake, it needs to take in a huge amount of power all

ofa sudden, and when he boosts, it has to act just as fast to

release it again. In layman’s terms, it’s like this: if the dis-

charged lithium-ion battery in a smartphone had the power

density of a 919 battery, it would only take about twenty

seconds to charge it to 100 percent. The disadvantage would

be: a very short call – and then all the juice would be gone

again. The energy density, in other words the battery capacity,

is crucial to keep the smartphone running for days on end.

If we transfer this to an electric car for everyday use, battery

capacity means range. “This is where the requirements of

race cars and electric cars for the road differ,” says Hitzinger,

“but, for the 919, we have advanced into in the area of hybrid

management to an extent that was previously unimaginable.”

In the MissionE, so-called permanent magnet synchronous

engines are provided – in effect these are the non-racing

brothers of the motor generator unit (MGU) from the winning

Le Mans car. “The 919 was the testing ground for the volt-

agelevel of hybrid systems,” Hitzinger says, not without pride.

This experience gave our production series colleagues the

courage to introduce the Mission E design study with 800-volt

technology. From the race track to the road: perfect team-

workà la Porsche.

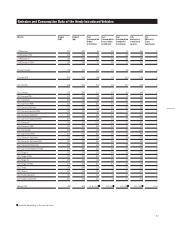

> 500 hp

Performance and Eciency:

a V4-cylinder engine with direct

fuel injection, turbo charger and

exhaust energy recovery system

> 400 hp

The Single Electric Engine

provides its power on demand via

a differential on both front wheels.

The state-of-the-art battery power

centre is positioned in the centre

of the vehicle.

93