Porsche 2015 Annual Report Download - page 124

Download and view the complete annual report

Please find page 124 of the 2015 Porsche annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Logistical Backbone in Sachsenheim

The central spare parts warehouse in Sachsen-

heim is Porsche’s logistical backbone. It is located

19kilometres from the headquarters in Zuffen-

hausen. 100,000 spare parts and 35,000 develop-

ment parts are handled over a storage space

of170,000 square metres. Over 400 employees

process up to 23,000 tickets every day, from

incoming orders through to dispatch. The specially

developed tugger train concept ensures that

operations run smoothly and on schedule. The

tugger trains run continuously between the

46stations on the plant grounds. Like all of the

vehicles in the warehouse, even the tuggers

areall-electric. The location generates its own

energy. 8,500 photovoltaic modules over an

area of 40,000 square metres provide around

two million kilowatt-hours of electricity every

year. The location also has its own combined heat

and power plant.

New Toolmaking Division

The sports car manufacturer acquired the tool-

making division of Kuka Systems GmbH in the year

under review and continued to operate the divi-

sion as a wholly owned subsidiary of Porsche AG.

Over 600 employees at Porsche Werkzeugbau

GmbH’s locations in Schwarzenberg in the

German state of Saxony and Dubnica in Slovakia

strengthen the Company’s expertise, especially

inthe production of complex aluminium parts.

The subsidiary specialises in method planning,

engineering design, toolmaking and systems

solutions for forming and cutting tools in the

automotive sector. It has already built tools for

the side panels of Porsche’s Panamera and

Macan models.

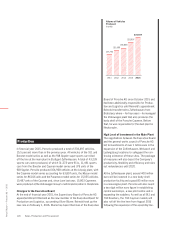

Customers Vouch for Premium Quality

The Porsche brand enjoys an excellent reputation

in the leading markets of the U.S., China and

Europe. According to U.S.-based market research

institution J.D. Power, the sports car manufac-

turer is top-rated by U.S. and Chinese customers,

for instance. The U.S. customer survey named

Porsche as the highest-quality brand for the third

year in a row. As in 2013 and 2014, Porsche was

placed first overall in the 2015 “Initial Quality Study”,

in which J.D. Power surveyed 84,000 buyers of

2015 models in the U.S. exactly 90 days after

registration of their new vehicle. The overall rating

is based on 233 different categories including

handling and design, as well as practicality and

vehicle comfort. The Porsche 911 was ranked

highest by U.S. customers for the fourth con-

secutive year and received the J.D. Power Award

for the vehicle with the highest customer satis-

faction in the “Midsize Premium Sporty Car”

segment. The Boxster also proved a recipe for

success in the year under review: for the third

time in a row, the mid-engined roadster placed

first in the “Compact Premium Sporty Car”

segment, followed directly by the mid-engined

Cayman Coupé.

Porsche was ranked the top premium automotive

brand by Chinese buyers. The Macan took first

place in the mid-range premium SUV category

in the “2015 China Initial Quality Study” (IQS).

The study is based on feedback from around

21,700 Chinese new car owners who purchased

vehicles between October and June 2015.

Procurement

Porsche AG added attractive vehicle projects to its product range in

financial year 2015. For instance, procurement successfully ramped

upambitious projects such as the 911 GT3 RS, the Cayman GT4, the

Boxster Spyder and the latest 911 generation with turbo engines thanks

toclose cooperation with our supplier partners.

An additional highlight over the past year was the stellar motorsport

season. Porsche claimed all of the World Endurance Championship titles

and celebrated a double victory at Le Mans. The brand’s winning finish

tothe season once again underscored Porsche’s successful year. Procure-

ment brought the right partners for our motorsport strategy on board

incollaboration with all of the departments involved.

Procurement of Production Materials

As in years past, the cost of materials per vehicle was optimised in

financial year 2015. Long-term cost savings were achieved through close

cooperation with and the early involvement of our business partners in

Annual Report — Porsche AG — 2015

Sales, Production and Procurement120