Porsche 2015 Annual Report Download - page 40

Download and view the complete annual report

Please find page 40 of the 2015 Porsche annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Foresight

Trust

Motivation

Dynamics

Freedom

Inspiration

Transparency

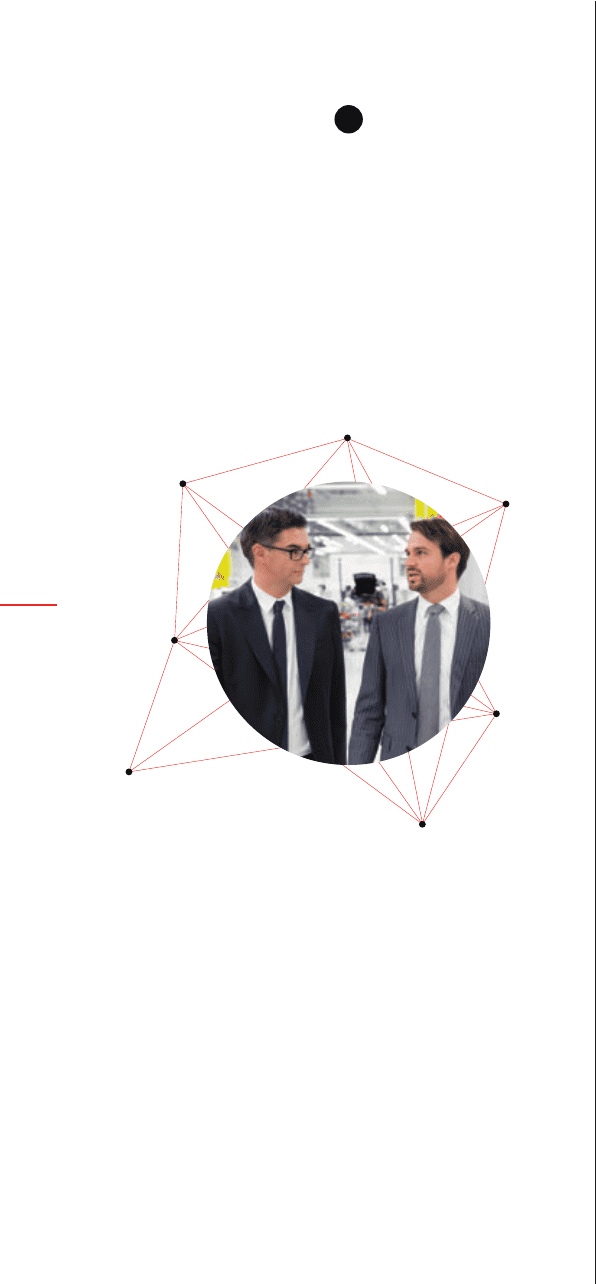

On a Straight Path

to Improvement

Openness creates trust, and discussions are best carried out

with the object directly at hand – Kai Maring (left) and Andreas

Juchem are at home in Porsche’s culture of innovation.

Blume brings a clear message with him: short channels, flat

hierarchies and an open exchange of ideas. At nearly every

opportunity, he encourages people to use the best of the

Volkswagen Group for Porsche without neglecting the culture

typical of Porsche. That means preserving the manufactory

concept and at the same time bringing in the potentials from

large-scale series production. With this pragmatic style of

acomprehensive transfer of know-how and with his openness

and fresh approach, Blume has generated strong motivation

and a mood of optimism.

Kai Maring and Andreas Juchem are two employees who have

experienced him live at fireside chats. Juchem already knew

Blume because he was a mechanical engineer in Leipzig for

two years, when production work on the new Macan was being

prepared there. At that time, Blume came to the plant in Sax-

ony every week. That made the Macan launch a topic of con-

versation, of course, at later fireside chats. Building a new

vehicle with a new team at a new plant in Leipzig was a special

challenge for everyone, Blume included. Some compare it

with climbing up an 8,000-metre mountain without oxygen.

But unlike lone wolves such as mountaineer Reinhold Messner,

only an experienced team can manage such a project in the

automotive world.

“As a bodywork specialist, Blume was very much involved in

the corresponding topics,” says Juchem, describing Blume’s

approach. Such phases call for pragmatic and fast solutions.

Ifa detail remains unclear after a discussion like that, Blume

often says, “Just send me the info per SMS afterwards.” Or

hesorts out a detail on the way to the canteen, at a chance

meeting on the treadmill at a Leipzig hotel or at another

chance location. One thing becomes clear again and again:

Blume loves discussing things directly on the object itself –

without an endless presentation at a long meeting. “Let’s go

straight to the vehicle – that’s one of his favourite sentences,”

says Juchem.

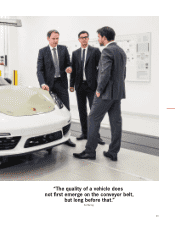

For Kai Maring, the Macan launch was the greatest challenge

in his career to date. And yet the vehicle and its quality already

take on life before the actual assembly on the production

linein Leipzig. The process already gets underway beforehand

among Porsche’s suppliers who manufacture complex con-

struction components. As such, the Macan’s clamshell-type

bonnet is an extremely demanding part of the bodywork. It

isproduced in a Group plant in the Slovakian city of Bratislava.

“There are only a handful of press lines that manufacture

acomponent of this size in the world,” says Maring. And

because the high-end bonnets have to travel 650 kilometres

from Bratislava to the Leipzig plant, a special load carrier

turned out to be the decisive link between the production

sites. It enfolds the component like the proverbial kid gloves

and protects it from the sometimes rough world of transport.

36

Annual Report — Porsche AG — 2015

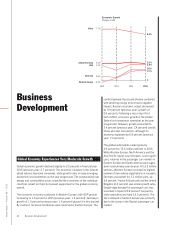

Success Factor: Human Capital