Nissan 2011 Annual Report Download - page 7

Download and view the complete annual report

Please find page 7 of the 2011 Nissan annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Shifting Gears from Recovery to Growth

Fiscal 2010 was a year in which Nissan intended to shift gears from recovery to growth. We

accomplished a number of challenging goals. Some examples are full-fledged production of our global

compact car, Nissan March, in Thailand, and the start-up of our Chennai Plant in India; the expansion of

our PURE DRIVE lineup, including the introduction of the Fuga HEV equipped with our original hybrid

technology; and the launch of the Nissan LEAF, representing our zero-emission leadership, in Japan,

the United States and Europe. At the same time, we executed all the tasks defined in our Recovery

Plan, such as promoting localization to increase resilience against a strong Japanese yen, cutting costs

to counter raw material price hikes and improving the profitability of each product. As a result, we

increased our market share in nearly all the regions and main markets that we operate in, and our

global sales reached a record high of 4.185 million units.

Reacting Quickly to Unprecedented Natural Disaster

Natural calamity struck Japan on March 11, 2011, when the company was about to resume a growth

trajectory after recuperating from the global financial and economic crisis that began in 2008. The

impact of the catastrophe was far bigger than we initially imagined. We suffered the loss of five

employees and associates in our group, including affiliates and dealers. Some 17% of our outlets in

Japan were damaged in the Tohoku region where the quake was centered. Facilities collapsed or were

damaged at the Tochigi Plant and the Iwaki Plant nearest to the epicenter.

Despite the phenomenal devastation, Nissan responded with swift and focused actions as we have

done in the past. The disaster response simulations we have carried out regularly served us particularly

well. By envisioning a full range of potential situations arising from a major disaster and preparing for

them, we successfully enabled ourselves to take prompt actions when the time came.

At a time of disaster, it is essential to make speedy decisions while grasping the latest situation,

including details on employees’ safety and damage caused, and to take appropriate actions based on

this. We launched the Global Disaster Control Headquarters just 15 minutes after the earthquake

occurred. The team immediately gathered and assessed damage while overseeing restoration efforts at

various facilities. The management power that Nissan has been building over the years was on full

display in the initial stages. Hundreds of people from other plants were mobilized to take part in

restoration work at affected facilities. Thanks to their hard work, we restarted production at all our

vehicle plants in Japan one month after the earthquake. The Iwaki Plant, which was the hardest hit,

resumed full operations on May 17, and is ready to produce at a pre-earthquake level as long as

necessary parts are supplied.

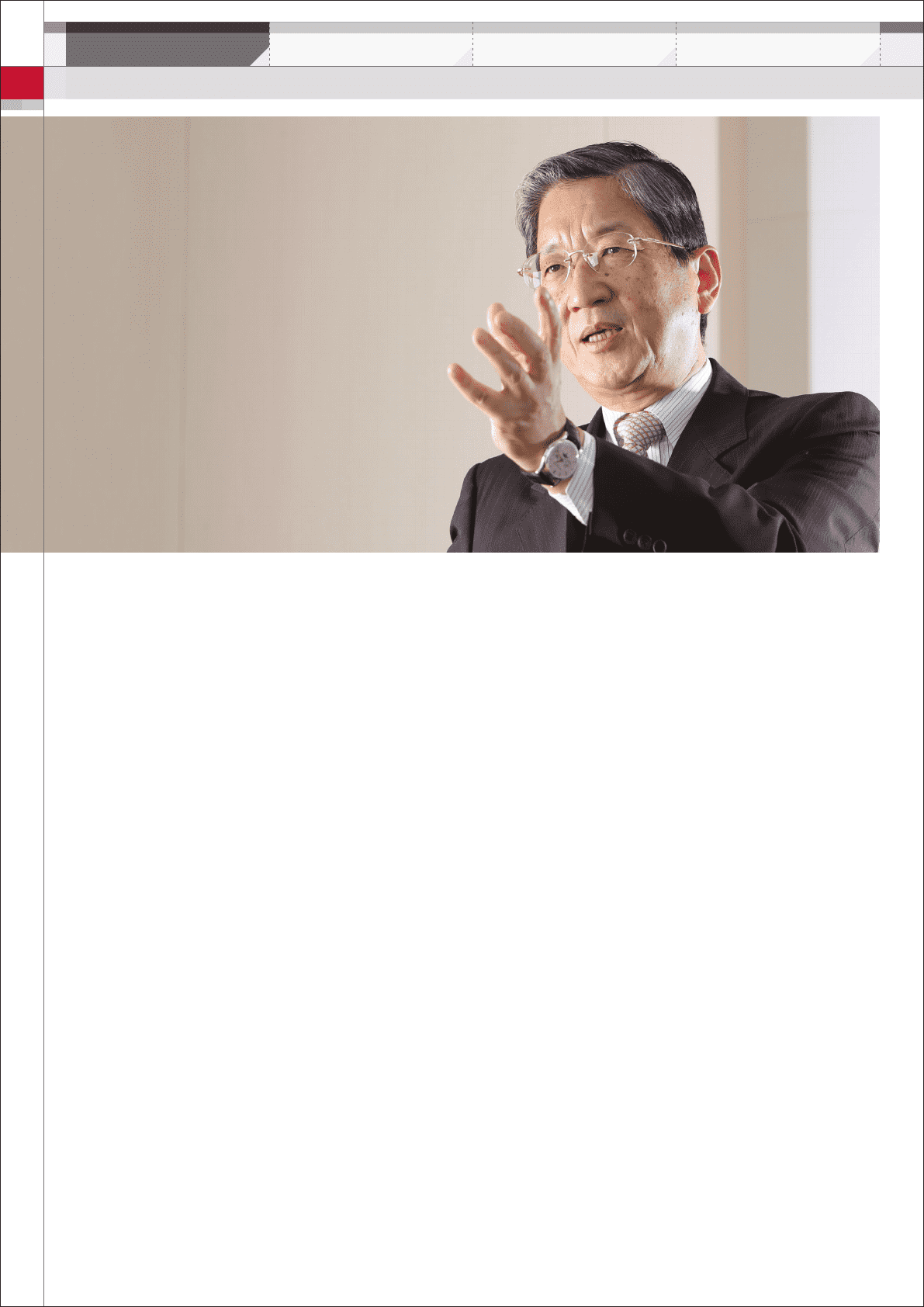

Toshiyuki Shiga Chief Operating Officer

A massive earthquake and tsunami shook

Japan in March 2011. The disaster deeply

affected Nissan’s operations, but the company

has marshaled its forces in an all-out effort to

restore normalcy quickly. We are displaying

our monozukuri (manufacturing) excellence to

pursue further growth.

The Fusion of Management

Power and Gemba Power

Message from the COO

Mid-term Plan

Performance Corporate Data Corporate Governance

06

NISSAN Annual Report 2011