Nissan 2011 Annual Report Download - page 39

Download and view the complete annual report

Please find page 39 of the 2011 Nissan annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Maintaining Trust Through Transparency

As described above, Nissan is implementing thorough quality checks before new model launches.

Nissan is advancing quality improvement activities also after launch by gathering quality information

from markets and promptly deploying countermeasures. In case of occurrence of safety or

compliance issues, necessary actions such as recalls are implemented with close cooperation with

market side team based on a management decision reached by an independent process. Incidents

are thoroughly investigated, analyzed and fed back to models on the way of production or

development for prevention of recurrence. In addition to the above described activities, such as

quality assurance at new model project and quality improvement activities on daily basis, the “Quality

Risk Management” framework has been newly developed from fiscal 2009. This is a high-level

system to ensure successful quality management for on-going and future projects. This includes

assessment of quality related risks, evaluation of risk level, assignment of responsible persons based

on the level and clarification of an organization for follow up. These processes are implemented by

the Quality Risk Management Committee, chaired by an EVP twice a year.

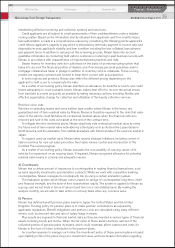

3) Environment, Climate Change

The automotive industry is affected globally by various regulations related to the environment and

safety, such as exhaust emissions, CO2/fuel efficiency, noise and recycling, and these regulations

are getting more stringent year by year. In this environment, one effective solution from a long-term

perspective will be widespread use of zero-emission vehicles. Nissan has started sales of the Nissan

LEAF, the world’s first affordable, mass-produced EV, in 2010. As the Renault-Nissan Alliance, we

have promoted partnership formation to develop a zero-emission society with national and local

governments.

Additionally, Nissan will reduce CO2 emissions by continuously developing technologies to

improve fuel efficiency in internal combustion engines and bringing them widely into the market. In

particular, we will promote low CO2 output technologies named PURE DRIVE, such as our hybrid

system, fuel efficient direct injection engine and continuously variable transmission (CVT).

Stricter controls on the environmental impact of substances are being sought in countries around

the world. Nissan has steadily advanced efforts to meet these requirements. In an effort to reduce

the potential release of environment-impacting substances, we have established voluntary standards

to meet the environmental regulations enacted in countries where we do businesses.

Demand for natural resources such as metals and oil is skyrocketing in response to the rapid

economic growth of emerging countries. In addition to promoting reduced use of virgin natural

resources through resource-saving and resource-recycling measures, it is becoming important to

procure natural resources that have a lower impact on the Earth’s ecosystems, not only from the

standpoint that these resources are limited, but also considering the wide-ranging effects that

resource extraction has on ecosystems. Nissan has targeted 100% resource recovery for end-of-life

vehicles (ELVs), while also promoting design centered on the vehicle life cycle, waste reduction and

promotion of expanded use of recycled materials.

The issue of water resources is becoming ever more serious with the retreat of glaciers and

rainfall fluctuation due to climate change in addition to increasing water use due to the growing

world population and economic development. Nissan, which uses water resources in its production

process, deeply recognizes the importance of this issue and is working to preserve water resources,

such as by reducing consumption and recycling water discharged in the production process.

The purchasing divisions of Nissan and Renault carry out supply-chain management in a manner

consistent with The Renault-Nissan Purchasing Way, a booklet outlining policies for dealing with

suppliers, and the Renault-Nissan CSR Guidelines for Suppliers. With respect to environmental

issues, we have set standards for the efforts of our automobile parts and material suppliers in the

form of the Nissan Green Purchasing Guidelines. Through these purchasing guidelines we seek to

share our environmental principles and action plans with our suppliers and to promote the reduction

of environmental impact throughout the entire supply chain.

Thus, Nissan is working to achieve autonomous guidelines and targets as part of its corporate

social responsibility as well as to comply with laws and regulations. In order to promote this

environmental management on a global basis, the Global Environment Management Committee

(G-EMC) chaired by the COO makes decisions on general direction and proposals to the Executive

Committee. The Global Environmental Planning Office decides concrete actions for each function

and conducts effective follow up of the progress based on PDCA (Plan-Do-Check-Act) management.

Corporate Governance

Performance Corporate DataMid-term Plan

38

NISSAN Annual Report 2011