Nissan 2011 Annual Report Download - page 38

Download and view the complete annual report

Please find page 38 of the 2011 Nissan annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Maintaining Trust Through Transparency

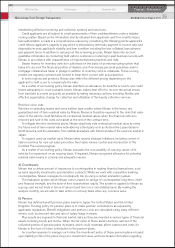

asset allocation of other corporates’ pension plans.

In addition, Nissan convenes Global Pension Committees on a periodic basis to review investment

performance, manager performance, review asset allocations and discuss other issues related to

pension assets.

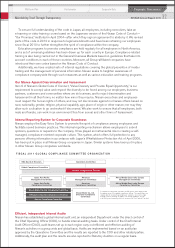

2. Business Strategies, Keeping Competitive Edge

1) Product Strategy

To secure our profitability and sustainable growth based on our future product lineup plan, in our

product strategy developing process, we are monitoring the impacts of some different types of risk

scenarios such as global market changes and demand deteriorations to our future profitability (COP)

based on our plan.

<Example of Risk Scenarios>

1. Drastic decline of total global demand, past examples as reference case.

2. A demand shift between vehicle segments drastically faster than our assumptions in our mid-

term planning.

3. A demand shift from the matured markets to the emerging markets drastically faster than our

assumptions in our mid-term planning.

We periodically monitor the impact of these scenarios to secure our future profitability and

sustainable growth, and also update our future lineup plans periodically based on the results. To

improve the robustness of our product lineup against these risks, we take the following

countermeasures as our main direction when planning our product strategy.

Expand availability of individual products across markets to mitigate the risk of single market

demand fluctuations.

Increase volume and efficiency per product through a consolidation and rationalization of the

portfolio to lower the breakeven point and thereby reduce the profit risk of global Total Industry

Volume declines.

Prepare a more balanced product portfolio meeting needs in a broader range of markets and

segments reducing reliance on specific large markets.

2) Quality of Products & Services

Nissan is working on the corporate task named “Quality Leadership,” aiming to be recognized as a

top-level quality brand by fiscal 2016. In this project, actions are carried out with numerical targets

for the following areas.

1. Perceived quality & attractiveness: Customers’ impression of a vehicle’s quality when customer

looks at it in a dealer’s showroom

2. Product quality: Quality of product itself based on the experiences as an owner of the vehicle

3. Sales & service quality: Quality related to behavior or attitude of sales staff or quality of service

during inspection and maintenance

For example, the target for “Product quality” is to attain the top level in Most Influential Indicators

(MIIs) in each region. In order to achieve the target, it is broken down to internal indicators by model

which correlate with MIIs. Progress of all quality improvement activities is monitored with those

internal indicators. All the actions are taken based on a rotating PDCA cycle: for example, the

progress of activities are monthly and globally reviewed by a Quality Committee chaired by an EVP

and necessary actions are decided.

Once a year, chaired by the COO, the Global Quality Meeting is held with persons responsible for

global quality to confirm the progress of Nissan quality improvement globally.

With respect to new model projects, in order to achieve the quality target of each project,

milestone meetings set each key process of design, prepare for production and production, confirm

key check points, such as achievement of quality targets, adopt measures to prevent recurrence of

past problems, and adopt measures for potential risks related to new technology and mechanisms

and design changes.

Commercial production can be started after confirmation at the SOP (Start of Production)

Judgment Meeting, which confirms all issues are solved and quality target can be achieved. Final

decision that the model can be sold is made at the Delivery Judgment Meeting after confirmation of

quality of commercial production and preparedness for service/maintenance.

Corporate Governance

Performance Corporate DataMid-term Plan

37

NISSAN Annual Report 2011