Nissan 2011 Annual Report Download - page 43

Download and view the complete annual report

Please find page 43 of the 2011 Nissan annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Maintaining Trust Through Transparency

HR/Workforce Facilities/Equipment

3 elements of

production

• Reinforcement of office buildings

(completed)

• Development of earthquake response

manual, implementation of

evacuation drills (once/year)

• Activity to improve registration

ratio to employees safety

confirmation system

• Assessment of earthquake

preparedness of major suppliers

located in high quake-risk areas

(FY08)

• Planning to adopt damage

reporting system on web base

(FY10)

• Reinforcement of buildings &

machinery (continued)

• Improvement of facility recovery

manual (FY09)

• Risk assessment based on F-PES

(Fire Prevention Evaluation

System) (once/year)

• Same as on the left • Same as on the left

• Revision of equipment standard

based on the assessment result

• Same as on the left• Risk assessment based on SES

(Safety Evaluation System)

(once/year)

• Assessment for health & safety

management system (once/year)

• Same as on the left

• Development of flu response

manual (FY09)

• Requested suppliers to develop

response manual coordinated with

Nissan

—

• Backup from other Nissan plants

(as needed)

• Backup from other companies (as

needed)

• Employment of short-term

employees (as needed)

• Regular check of demand

projection and supply capacity;

implementation of measures

• Installation of flexible

manufacturing system (completed)

• Regular check of demand

projection and production capacity;

implementation of measures

• Development of complementary

production system for main power

trains

—— • Share past incident experiences

and reflect them in preventive

maintenance

• Reflect them in equipment

standards

• Assessment of monozukuri ability

before supplier sourcing and

support for improvement activities

after sourcing

• Quality assessment at production

preparation phase

• Quality check at mass production

phase (action “Gate 1-3”)

—

—

• Plan to rebuilt of HR development

System (FY10)

——

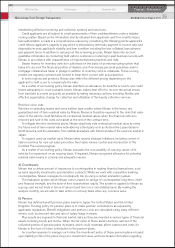

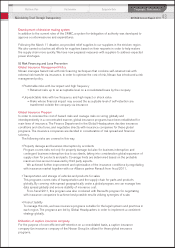

Natural disasters (earthquakes)

Fire

Workplace injury

Pandemic

Demand fluctuation

Machinery breakdown

Expanding LCC parts

adoption

Decrease of skilled workers/

experts

Risk factor

Purchased parts/

Raw materials

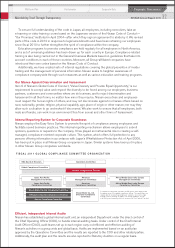

4) Supply Continuity

Control was enhanced as follows to prepare increase of suppliers’ credit risk.

Risk assessment

In addition to the management that has been continuously done, such as control based on financial

assessments of each supplier and management by the Suppliers Risk Management Committee

(SRMC), monthly reports of suppliers’ risk situations and expected extra expenses were started on a

global basis. The establishment of a monitoring system has also started, allowing Nissan and

Renault to monitor their suppliers’ risk commonly and constantly on a global basis.

Contingency plan

In order to respond timely and agilely in case of contingency, a cross functional committee was

formed and this enabled prompt decision making.

Corporate Governance

Performance Corporate DataMid-term Plan

42

NISSAN Annual Report 2011