Porsche 2010 Annual Report Download - page 73

Download and view the complete annual report

Please find page 73 of the 2010 Porsche annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.Das Unternehmen

tries in 2010 with the cooperation of the Volks-

wagen group’s importers.

The knowledge gained from this program is

an integral part of the measures that the Volks-

wagen group is taking to drive up Volkswagen’s

quality in the markets and increase customer satis-

faction – one of the main objectives of the group

Strategy 2018. The aim is to secure a pole position

in terms of customer satisfaction and brand loyalty

with the Volkswagen passenger cars brand and its

products by 2018 at the latest. All areas of the

company are working hard to achieve this goal. The

large-scale activities are coordinated by the Quality

Assurance and Sales functions and are regularly

presented in the “Customer Satisfaction Forum”.

The defined target of obtaining a leading position in

terms of customer satisfaction and customer loy-

alty applies equally to all other group brands, which

are developing and implementing measures in their

own programs and bodies for this purpose.

In spite of the large number of production

start-ups and the growing volume of vehicles manu-

factured, the Volkswagen group’s high level of qual-

ity was reaffirmed in 2010 across all group brands

and corporate locations and the number of repairs

was maintained at a consistently low level.

The Volkswagen group’s production locations

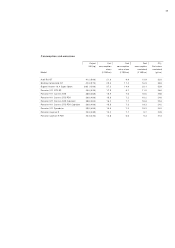

At the end of 2010, the Volkswagen group

had 61 locations, with production facilities at 40 of

these. After commencing full production in 2009,

the Russian site in Kaluga added two more vehicle

models to its production range, bringing the number

of vehicle launches to four in just eleven months.

The facility in Pune, India, now produces a total of

four different models as well. Construction is pro-

gressing at the Volkswagen plant in Chattanooga,

USA, where production of a model developed spe-

cially for the North American market will begin in

2011. Volkswagen Osnabrück GmbH will also start

building vehicles in the same year. In China, the

group – in line with its long-term growth strategy –

is building two new vehicle plants in Yizheng and

Foshan, both of which will become operational in

2013. The new engine plant in the Mexican city of

Silao will start producing the latest generation of

engines for the North American market in the same

year. Following an extensive overhaul, Scania now

has efficient, state-of-the-art bus production at its

site in Slupsk, Poland. Volkswagen’s plant in Chem-

nitz, Saxony, was rated “Factory of the Year 2009”

in the “outstanding innovation management” cate-

gory by management consultants A.T. Kearney and

the German magazine “Produktion”.

The Volkswagen group’s production system

The Volkswagen group’s value-driven syn-

chronous production system has been designed

with the aim of improving quality and adherence to

schedules while simultaneously reducing costs. The

core element of the system is a consistent, sys-

tematic organization of work and processes that will

be achieved through a uniform group-wide produc-

tion system and the methodical approach of the

continuous improvement process. Employees, em-

ployee representatives and management have to-

gether made it their business to turn the company

into a learning organization.

Around the world, Lean Centers are cur-

rently being established in the group brands along

with training centers at the plants. These will offer

training courses for employees, from skilled work-

ers to top managers, thus broadening their fields of

expertise. The Lean Center in Chattanooga opened

its doors in 2010; other new training centers have

been set up at the Chemnitz plant for engine as-

sembly and at the Kassel facility for mechanical

production and gearbox assembly.

On account of the demographic trend,

Volkswagen is facing the challenge of achieving its

ambitious goals as the age structure of its work-

force changes. In this context, people are the

group’s most important resource. For employees to

keep performing at high levels, their workstations

must be designed ergonomically and appropriate to

their age. This must be taken into account early on,

in the product development process. By making

ergonomics a particular priority in this process,

71