LensCrafters 2014 Annual Report Download - page 26

Download and view the complete annual report

Please find page 26 of the 2014 LensCrafters annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

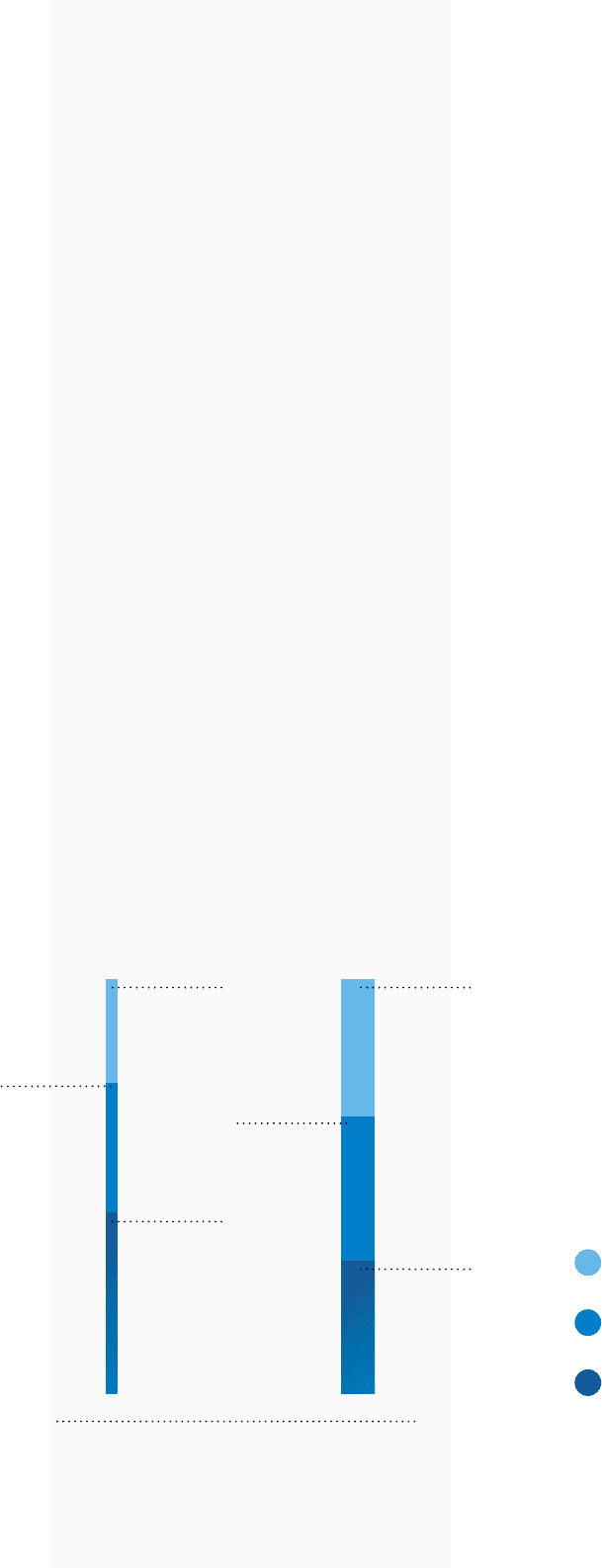

31%

2010

44%

25%

The manufacturing facility in Campinas (Brazil),

acquired in January 2012, produces both plastic and

metal frames for the Brazilian market. In September

2012, Luxottica launched the first locally designed

and produced Vogue Eyewear collection for this

market. Between 2013 and 2014, the Company

added the production of select Ray-Ban, Arnette

and Oakley collections. In 2014, the Campinas plant

produced approximately 50% of the eyewear sold by

Luxottica in the Brazilian market.

Over the years Luxottica has progressively diversified

its technology mix from traditional metal, plastic

injection and acetate slabs to include aluminum,

wood, die casting, fabrics and the LiteForce material.

This technology shift has reduced the weight of

metal-based frames from 44% of total production

output in 2010 to approximately 30% in 2014.

The manufacturing process for all frames begins with

the creation of precision tooling and molds based

on prototypes developed by in-house designers and

engineering staff.

Metal frames

Luxottica’s manufacturing process for metal frames

has approximately 70 different phases, beginning

with the production of basic components such as

rims, temples and bridges, which are produced

through a molding process. These components are

then welded together to form frames over numerous

stages of detailed assembly work. Once assembled,

the metal frames are treated with various coatings

to improve their resistance and finish, and then

prepared for lens fitting and packaging.

Plastic frames

Plastic frames are manufactured using either a milling

or an injection molding process. In the milling process,

a computer-controlled machine carves frames from

colored acetate slabs. This process produces rims,

temples and bridges that are then assembled,

finished and packaged. In the injection molding

process, plastic resins are liquefied and injected into

molds. The plastic parts are then assembled, coated,

finished and packaged.

Acetate

Injected

Metal

2014 ANNUAL REVIEW

24

Technology breakdown

2014

35%

32%

33%