LensCrafters 2014 Annual Report Download - page 25

Download and view the complete annual report

Please find page 25 of the 2014 LensCrafters annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

The next steps in the process involve the production and

quality certification of sales samples of the new models.

These samples are subjected to another sequence of tests

to verify the quality of the engineering. The final step is the

production of a preliminary batch using definitive tooling

certified by an external standards organization. These

samples are produced in a pilot facility that resembles the

plant chosen to manufacture the final product for consumers.

Manufacturing

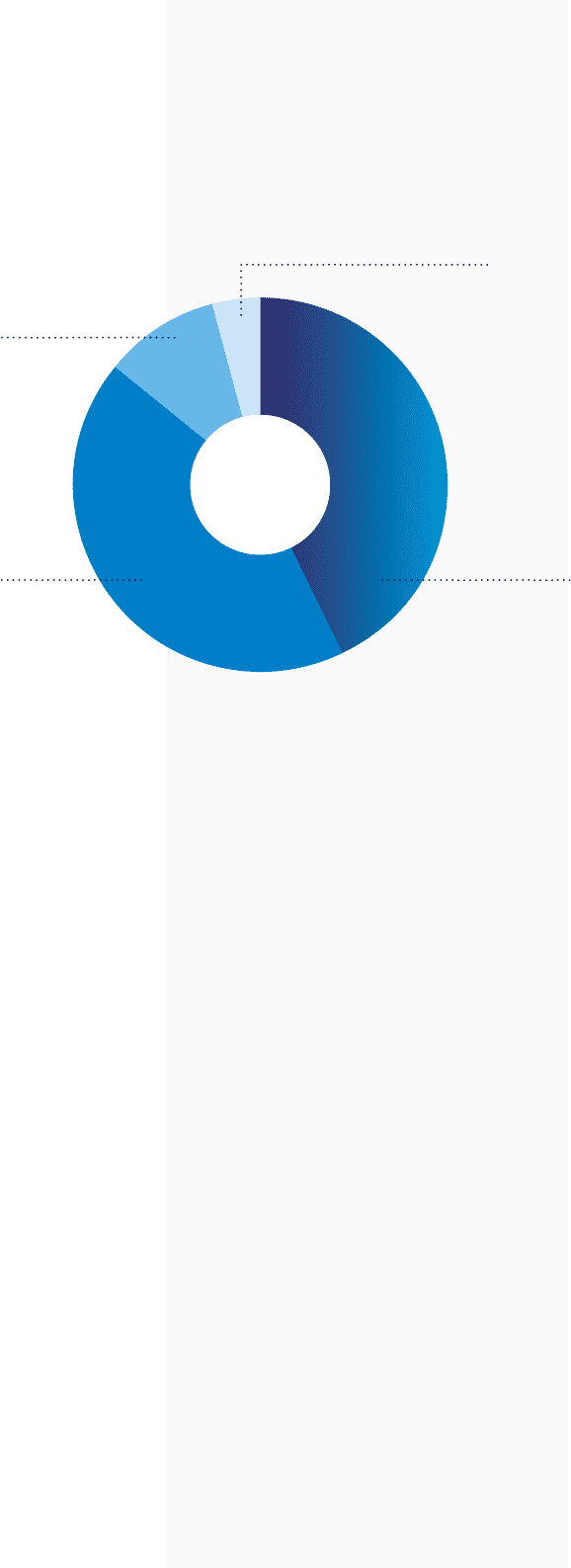

In 2014, Luxottica’s manufacturing facilities, located in

Italy, China, India, the United States and Brazil, produced

a combined total of approximately 83 million prescription

frames and sunglasses.

Six manufacturing facilities are located in Italy, which is at the

center of Luxottica’s luxury eyewear production, combining

the tradition of Italian craftsmanship with the speed and

efficiency of modern automation. These factories represent

43% of global production output. Five facilities are located

in Northeastern Italy, where most of the country’s eyewear

industry is based, and one is located near Turin. Over the years,

the Group has consolidated its manufacturing processes

and allocated specific production roles and technologies to

each plant. This has enabled Luxottica to improve both the

productivity and quality of its manufacturing operations.

The three manufacturing facilities in China and a small

plant in India collectively represent another 43% of total

production output. From 1998 to 2001, Luxottica operated

the Dongguan plant in China’s Guangdong province through

a 50%-owned joint venture (Tristar Optical Company Ltd.)

with a Japanese partner. In 2001, Luxottica acquired the

remaining 50% interest in this Chinese manufacturer and

in 2006, it increased its manufacturing capacity in China

through the construction of a new manufacturing facility to

produce both metal and plastic frames. With the opening

of this new facility, the annual average daily production in

China increased by approximately 80% from 2005 to 2006. In

2010, its Tristar facility started producing plastic sun lenses to

be paired with frames manufactured in the same location. In

2013, Luxottica integrated into its manufacturing processes

a newly developed state-of-the-art plant, partly dedicated

to decorations, utilizing techniques adapted from other

industries.

The Foothill Ranch facility in California manufactures high-

performance sunglasses, prescription frames and lenses

and assembles most of Oakley’s eyewear products. Oakley

apparel, footwear, watches and certain goggles are produced

by third-party manufacturers.

Group production

output

Brazil

4%

United States

10%

China & India

43%

Italy

43%

2.4

23