JVC 2002 Annual Report Download - page 19

Download and view the complete annual report

Please find page 19 of the 2002 JVC annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Lowering JVC’s breakeven point in sales, on a non-con-

solidated basis, from ¥6 0 0 billion to ¥50 0 billion, is an

integral part of our plans to build a more resilient oper-

ating structure. Only bold reorganization of the

company’s employment structure, reduction of inven-

tory and procurement costs, and realignment of our

manufacturing facilities will produce the desired results.

We have already made progress in these areas.

Our plans to streamline the workforce are one year

ahead of schedule: JVC’s domestic workforce will fall

to 8 ,2 0 0 by the end of fiscal 2 0 0 3 , down from 9 ,39 9

at the end of fiscal 2 002 . As part of our efforts to

reduce inventories, we will install an IT-based SCM

system at our U.S. operations in October 20 0 2 . This

will enhance inventory turnover from the current 4 8

days to 3 8 days by the end of fiscal 2 0 03 . We aim to

reduce inventory turnover to less than 3 0 days by

extending this SCM system to all our operations in

April 2 00 3 . Meanwhile, we are working to pare back

procurement costs by around 2 0% by focusing on

Value Engineering (VE) in design processes. During

the year, we made significant progress in realigning

our manufacturing activities. This included closing

domestic plants in Isesaki and Ebina, and withdraw-

ing from low-end television manufacturing in China

and unprofitable businesses, such as magnetic heads.

These steps to realign JVC’s manufacturing stance

are part of a global picture where we are shifting pro-

duction to optimal locations. This will see plants in

Japan positioned as “mother” manufacturing facilities,

and the development of products destined for Asia,

Russia, and the Middle and Near East transferred from

Japan to other regions in Asia. This clear separation

of manufacturing functions will help to reduce fixed

costs and lead to the development of products closely

suited to consumer needs in specific markets.

To keep abreast of shortening product cycles, we

are also restructuring production processes based on

6 -month development and manufacturing timetables

and eliminating all inventories within the same time

frame. This timetable will form the basis of operational

cycles for our entire business and significantly reduce

the time it takes to commercialize new models. Product

planning capabilities will also be enhanced through the

participation of marketing personnel in domestic product

strategy meetings.

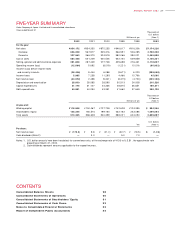

Total Assets Inventories

REDUCING TOTAL ASSETS

(Billions of yen) (Billions of yen)

0 1 /3

586.6

0 2 /3

513.4

Based on exchange rates for 0 1 /3

Manufactured Products

Materials & Assembly

0 1 /3 0 2 /3

155.3

126.1

Total assets reduced

by ¥7 3 .3 billion

Major reductions

• Inventories

• Loan repayments though effective

use of Group funds

• Fixed assets

Yen Exchange Rate 0 1 /3 0 2/3

U S$ 1 2 4 1 3 3

EU R 1 0 9 1 1 6

ANNUAL REPORT 2 0 0 2

1 7