Sharp 2010 Annual Report Download - page 19

Download and view the complete annual report

Please find page 19 of the 2010 Sharp annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Environmental Performance (1):

Eco-friendly, High-efficiency Manufacturing

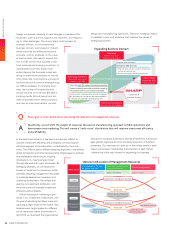

Major energy savings realized by integrated energy

management center

Conventionally, utilities such as electricity, gas and water are

managed separately at each plant. At GREEN FRONT SAKAI,

an integrated energy management center controls energy use

across the entire complex, realizing significant savings in

energy and resources. The systems at this facility allow con-

trollers to visualize energy

use across the complex in

real time, allowing them to

optimize energy control to

prevent waste and safety

problems.

Inter-building transport system for super-efficient production

Previously, the glass substrates and color filters used to make

LCD panels were delivered to the LCD panel plant each day

by trucks from their respective factories. At GREEN FRONT

SAKAI however, the factories are all in close proximity and are

connected by an inter-building transport system, allowing

smooth delivery of materi-

als as though they were

being transported within a

single plant. This cuts lead

times and reduces CO2

emissions from transporta-

tion, helping to realize

super-efficient operations.

State-of-the-art IT system for convergence of supply

chain management

IT systems are used at GREEN FRONT SAKAI to realize

highly efficient production. These technologies make the

entire supply chain flow visible—from production planning to

process management and shipment. They also improve effi-

ciency by allowing information about manufacturing at each

plant to be shared.

Environmental Performance (2):

Eco-friendly Design for the Entire Plant

Large-scale on-site photovoltaic power generation set-up

GREEN FRONT SAKAI features a large-scale photovoltaic

power generation system on rooftops and other spaces. This

system will be used to generate a portion of the power used

for production.

100,000 energy-efficient LED lights installed

Long-life, energy-efficient

LED lighting has been

installed throughout GREEN

FRONT SAKAI. The site also

includes LED lights fitted

with Sharp’s Plasmacluster

Ion generating units, as well

as solar-powered LED lights

for use outdoors.

Walkways constructed from recycled LCD panel waste glass

The walkways at GREEN FRONT SAKAI are made from propri-

etary porous blocks that incorporate recycled waste glass

from LCD panel production.

The material in the blocks

allows rainwater to pass

through and is expected to

help keep the walkways

from becoming hot.

On-site fleet of low-emission vehicles (LEVs)

To reduce CO2 emissions further, we will systematically intro-

duce a fleet of low-emission vehicles for on-site travel. These

will include LEVs powered by electricity and natural gas.

GREEN FRONT SAKAI Showcases High-efficiency

Operations Combined with Eco-friendliness

GREEN FRONT SAKAI is a showcase for creation of energy-saving LCD panels and energy-creating solar cells. The office facilities

on site also incorporate the latest in environmental technology, further reducing the overall environmental burden generated by

business activities.

Special Feature

Annual Report 2010 17