Loreal 2012 Annual Report Download - page 24

Download and view the complete annual report

Please find page 24 of the 2012 Loreal annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

UNIVERSAL

BEAUTY

IS

In parallel with the organization of our industrial facilities by region,

our plants are now being specialized by product type worldwide,

which is already the case at our 15 sites in Europe. Throughout

the zones, each plant specializes in a given expertise for greater

efficiency in terms of investment, and to accelerate productivity

gains. Advances made in rationalization and automation have

resulted in doubling productivity over the last 10 years.

JEAN-PHILIPPE BLANPAIN

EXECUTIVE VICE-PRESIDENT OPERATIONS

PLANT

SPECIALISATION

BY TECHNOLOGY

REMAINS A

SIGNIFICANT DRIVER

FOR PRODUCTIVITY

ACCELERATION.

AN EVOLVING

INDUSTRIAL

MODEL

With two new plants in 2012, L’Oréal has ac-

celerated its worldwide industrial roll-out. Located

in high-growth countries, Indonesia and Mexico,

these two new sites are key to the group’s univer-

salisation strategy.

DOUBLING OUTPUT

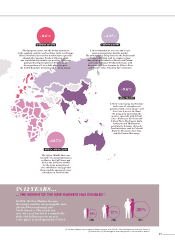

Winning a billion new consumers means doubling

the output of the group’s factories. In Operations(1),

the universalisation strategy is based on a single

industrial policy, organised on a regional basis

so as to stay close to markets, seize all opportuni-

ties and develop the talents of tomorrow through-

out the world.

In 2010, the inauguration of the factory at Kaluga

in Russia set the ball in motion. Built in response

to the powerful growth of the local market, with

a production capacity of more than 100 million

units, it also embodied the strategy Operations

had put in place: the regionalisation of industrial

facilities. With a production capacity of 500 million

units, the Jababeka plant, opened in Indonesia

in 2012, is set to become the cornerstone of

development in South-East Asia, the zone where

growth is highest and where L’Oréal has set itself

ambitious targets (see box opposite). Like all the

group’s other plants, it has been certified in terms

of quality, environment and safety.

Inaugurated at the end of the year in Mexico,

the San Luis Potosi plant is strategically located to

supply Latin America and North America with

hair colourants from L’ORÉAL PARIS, GARNIER and

SOFTSHEEN•CARSON. In the short term, this factory

will adopt the “wall to wall” approach initiated

by the group in 2010. This strategy calls for the

inclusion of a supplier’s packaging production

unit on-site in order to reduce response times

and increase productivity and flexibility. By 2013,

the plant’s production capacity will reach 120

million units, and by 2015, it is expected to attain

225 million units.

42

FACTORIES

WORLDWIDE

498,000

DISTRIBUTION POINTS

WORLDWIDE

(1) Operations at L’Oréal covers seven different fields: purchasing,

production, quality, environment-health & safety, supply chain,

packaging & development, and real estate.

22