Toyota 2014 Annual Report Download - page 12

Download and view the complete annual report

Please find page 12 of the 2014 Toyota annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

ANNUAL REPORT 2014

President’s MessagePresident’s Message

Overview of

Four Business Units

Overview of

Four Business Units

Special FeatureSpecial Feature

Review of OperationsReview of Operations

Consolidated Performance

Highlights

Consolidated Performance

Highlights

Management and

Corporate Information

Management and

Corporate Information

Investor InformationInvestor Information

Financial SectionFinancial Section

Page 12

NextPrev

ContentsSearchPrint

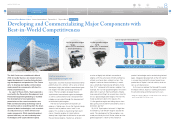

Further advances in key technologies

for hybrid technology

Hybrid technology can be applied to the develop-

ment of all sorts of environment-friendly vehicles

and can be found in a wide variety of powertrains.

Toyota has positioned hybrid technology as a

core environmental technology for the 21st

century. As a pioneer in the mass production of

hybrid vehicles, we are continuing to improve this

technology.

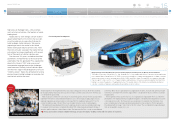

Power semiconductors have a big impact on

the effectiveness of hybrid technology. Hybrid

systems offer excellent fuel economy through the

efficient use of two power sources: gasoline

engines and electric motors. A large number of

power semiconductors are used in the power

control unit (PCU), a device situated between the

motor, power generator and batteries. The PCU

controls the output of the motor. Some of the

electrical current that flows through the power

semiconductors in the PCU is lost as heat; in fact,

approximately 20% of a hybrid vehicle’s overall

electricity loss is from the power semiconductors.

For this reason, making power semiconductors

more efficient will improve fuel economy. Toyota

has been developing its own power semiconduc-

tors as a key technology for improving fuel econ-

omy since the launch of its first-generation Prius

in 1997. In the latest, third-generation Prius, elec-

tricity loss has been reduced to a quarter of that

of the first-generation Prius.

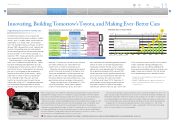

Aiming to make tomorrow’s Toyota better than

today’s, we are developing power semiconductors

that use next-generation silicon technology, namely,

silicon carbide (SiC), a material that is a compound

of silicon and carbon. We have already improved

fuel economy more than 5%* in a prototype

featuring the new SiC power semiconductors. As

early as possible, Toyota aims to commercialize

SiC power semiconductors that offer a 10%*

improvement in fuel economy through greater

efficiency. In addition, we aim to shrink the PCU

to one-fifth the size of current PCUs through

the use of SiC power semiconductors.

* Toyota estimate based on a prototype driven under the

Japanese Ministry of Land, Infrastructure, Transport and

Tourism’s JC08 test cycle parameters.

On September 25, 1945, soon after the end of World War II, the Allied Power’s General Headquarters in

Japan authorized the production of trucks and in principle allowed any company to produce and sell auto-

mobiles from October 25, 1949. The industry, however, was still in disarray.

In the 1950s, Japanese automakers were forging technological alliances with foreign automakers for the

production of passenger cars. Kiichiro Toyoda chose a different path in line with his father Sakichi’s admon-

ishment, “Before you say you can’t do something, try it.” Aiming to research and innovate on his own,

Toyoda embarked on the full-fledged development of a passenger car using home-grown technology. When

development began, Toyoda decided to name this new passenger car the Crown, feeling that this might be

his crowning achievement. However, he passed away suddenly in March 1952, before the completion of the

Crown, which featured cutting-edge technologies, including a front-axle double wishbone suspension.

Fulfilling Kiichiro Toyoda’s dying wish, the Toyopet Crown was finished in 1955 and launched as Japan’s first

full-fledged passenger car.

By October 1956, sales of the Toyopet Crown exceeded 1,000 vehicles per month, becoming a hit

among drivers enamored with its proprietary design featuring rear-hinged doors and a front-wheel indepen-

dent suspension for a smooth ride. With the popularity of the Crown, Toyota completed construction on the

Motomachi Plant in Aichi Prefecture in July 1959, only eleven months after the groundbreaking ceremony.

The plant was to produce 60,000 passenger cars per year.

Kiichiro Toyoda’s dream of mass producing a home-grown passenger car and sparking the development of Japan’s automotive industry had finally come true.

The PCU plays a vital role in controlling electricity usage,

recharging batteries with electricity generated when the

vehicle decelerates and accelerating the vehicle by supply-

ing electricity to motors from the battery bank while driving.

PCU with silicon power

semiconductors

(Production model)

PCU with SiC power

semiconductors

(Future target)

PCU volume: 1/5

Toyota’s

DNA

The Crown

Toyota in 10 Years and 100 Years [3 of 6] Our DNA is Creating Ever-Better Cars What Sets Toyota Apart Enriching Lives and Building Tomorrow’s Toyota through Innovation New Values for the Next Hundred Years Message from the Executive Vice President Responsible for Accounting