Nissan 2010 Annual Report Download - page 12

Download and view the complete annual report

Please find page 12 of the 2010 Nissan annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Chief Recovery OfficerColin Dodge

10

Powering Through the Crisis

Messa efrom the CRO

g

Entering the Next Phase:

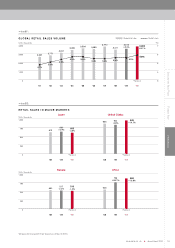

Not only were the results met, but they far exceeded our

expectations. In fiscal year 2009, consolidated operating

profit improved to 311.6 billion yen from an operating loss

of 137.9 billion yen in the prior year. We achieved our

monozukuri cost target, helped along by decreases of 134.4

billion yen in purchasing costs, 20.4 billion yen in

manufacturing costs, and 64.5 billion yen in R&D expenses.

Reductions in G&A expense were also a big factor. The

improvement in our income statement also led to our

achieving positive free cash flow of 375.5 billion yen for the

year. We also lowered our capital expenditures by 110

billion yen to 273.6 billion yen, which also contributed to

these results.

Higher sales, which led to an increase in production,

were another contributing factor to the positive results. Our

plants and supply chain team increased total volume by 6.4

percent to 3.282 million units. Another factor was how fast

our manufacturing group and suppliers responded to market

changes and new opportunities. For example, when the

various government stimulus programs emerged worldwide,

we responded quickly and delivered vehicles to those

markets offering subsidies. In contrast, many other

manufacturers took months to respond. That reflects the

DNA of a Japanese manufacturing company and represents

one of Nissan’s core strengths.

The recovery plan we put in place last year were

short-term measures designed to ensure Nissan’s

survival during the financial downturn. The objectives

of our recovery plan were to restore both positive free

cash flow and consolidated operating profit.

Reducing our cost base was a major element of the

recovery plan. One of the main pillars of the plan was to

reduce costs for monozukuri-related functions such as

engineering, purchasing, manufacturing, and supply chain

management by 5 percent. We also wanted to decrease

capital expenditures, as well as G&A costs, during the

downturn.