Kia 2002 Annual Report Download - page 10

Download and view the complete annual report

Please find page 10 of the 2002 Kia annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

2002 saw Kia make quantitative and

qualitative improvements in production.

��� The Kwangju Plant is being upgraded to produce fewer models in larger quantities w hile

facilities at the Hw asung Plant are being expanded beyond just automobile production.

��� Structural alterations at the Sohari Plant have improved logistics.

��� A daily ordering system speeds up customized production.

��� Quality is improved by integrating Kia and Hyundai quality assurance functions.

Production & Qualit y

2002 KIA MO TO RS AN N UAL REPORT

1617

Sweeping system improvements and innovations allow

Kia to increase production of high quality vehicles

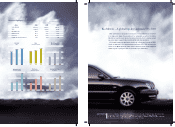

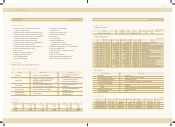

2000 2001 2002

400

300

200

100

IQS(Initial Quality Study) Index

Source : J. D. POWER

Kia Industry Average

295

262 231

133

150

157

Annual Production Capacity (units)

As of Dec. 31, 2002

Sohari

340,000

Hwasung

600,000

Kwangju

210,000

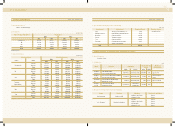

Kia’s aggregate production topped ten million units in 2002, and the annual production record w as broken for the second

straight year. These achievements w ere made possible by securing production quality and successfully launching many new

models, including the Sorento, the New Carens, the New Optima/M agentis, and the New Rio.

In 2002, w ork began at the Kw angju Plant to switch from low volume manufacturing of large number of models to the high

volume production of a smaller number of models. When the expansion project is completed, annual capacity will be increased

to 300,000 units. Facilities at the Hw asung Plant, meanw hile, are being expanded to produce not only automobiles but also

quality testing, engine production and greater w orker support. Structural alterations at the Sohari Plant have also been complet-

ed to improve logistics.

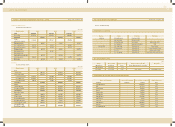

A new daily ordering system has been implemented in production related divisions to enable assembly to begin immediately

after customized orders are received. An online operations management system and an after-sales production control system

w ere developed to monitor production line status in real time. The supply of parts to after-sales service centers w as also com-

puterized to speed up the supply process w hile reducing required staffing levels.

Kia M otors and Hyundai M otor also integrated their quality assurance functions. Kia’s Initial Quality Study (IQS) results, w hich

directly affect overseas sales, w ere drastically improved w hile extra care w as taken to minimize quality problems w ith new mod-

els such as the Sorento. Employees w ere trained in new quality control methods to raise their awareness of quality issues. Kia

has been engaged in the Six Sigma quality program for three years and the results w on the company the Six Sigma Innovation

Aw ard at the Korean National Quality M anagement Conference in November 2002.

In 2003, efforts w ill focus on raising productivity through line adjustments, highly successful new model launchings and mini-

mal production flaws. Plans are in place for preventing quality problems by ensuring smooth labor relations. Proactive quality

assurance for new models and IQS quality innovations w ill be strengthened by focusing on quality issues from the R&D stage.

As a result, Kia’s reputation for quality will continue to grow .