Hyundai 2015 Annual Report Download - page 36

Download and view the complete annual report

Please find page 36 of the 2015 Hyundai annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

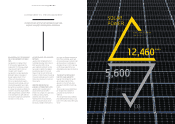

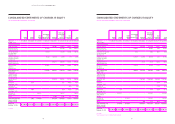

The Asan Plant generated 12,460 MWh

of renewable electricity in 2015 using its

rooftop solar system.

The 10MW rooftop solar generation

system can reduce GHG emissions by

5,600 tons per year.

12,460MWh

SOLAR

POWER

5,600t

CO2

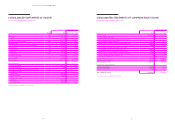

NEW MATERIALS AND TECHNOLOGIES

FOR A NEW GENERATION OF GREEN

CARS

Hyundai Motor has demonstrated

its technological capability with the

development of a three way catalytic

converter which meets California’s

stringent SULEV standard.

Hyundai Motor has been developing

lightweight design technologies to

improve quality in terms of fuel

efficiency to reduced emissions.

We are also developing bio plastics,

using plant-based materials, which are

already being applied in some models.

Bio plastics can contribute to as much

as a 40 percent reduction in lifetime CO2

emissions compared to regular plastics

made using petroleum. Sustained efforts

in the development of green materials

and new technologies will accelerate the

transition to a clean car era.

MINIMIZING WASTE AND MAXIMIZING

RECYCLING

Hyundai Motor established the first

Automobile Recycling Center in Korea

which processes 4,200 cars per

year. Significant investment has also

been made to minimize the negative

environmental impact of cars at all

stages of their life cycle. Efforts will

continue to further increase the amount

of recycled automobile parts in order to

retrieve more materials for reuse and

reduce waste.

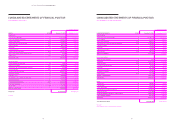

REDUCING GREENHOUSE GAS

EMISSIONS AT PRODUCTION PLANTS

Hyundai Motor is working hard to

reduce GreenHouse Gas (GHG)

emissions at all stages of its operations

including purchasing, logistics,

production, sales and service.

Since 85 percent of GHG emissions

are from production plants, we are

introducing a number of measures at

our plants, including the installation of

high efficiency facilities, waste heat

recovery and energy conservation. We

are also working on transitioning to

renewable energy. Our effort will help

us effectively respond to the ever-

strengthening GHG emissions reduction

policy.

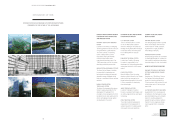

THE WORLD’S SECOND LARGEST

ROOFTOP SOLAR GENERATOR

Hyundai Motor installed the world’s

second largest solar electricity

generator at its Asan Plant, which

generated 12,460 MWh of electricity

in 2015.

This is enough to power 3,800 homes

for one year and contributes to

a reduction in GHG emissions of

5,600 tons.

The solar generator brings additional

environmental benefits because it was

built on the rooftop without destroying

nature.

HYUNDAI MOTOR IS SETTING NEW STANDARDS IN CLEAN CARS

BASED ON MAXIMIZING ENVIRONMENTAL CREDENTIALS.

COMMITMENT TO THE ENVIRONMENT

HYUNDAI MOTOR COMPANY Annual Report 2015

70 71