International Paper 2012 Annual Report Download - page 15

Download and view the complete annual report

Please find page 15 of the 2012 International Paper annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

THE MOGI GUAÇU BIOMASS BOILER

In 2012, we completed construction and start-up of our biomass boiler in Mogi

Guaçu, Brazil. This high-return cost savings project stands proudly at the

intersection of sustainable solutions and innovative cost management, with an

estimated $30 million in incremental earnings between 2012 and 2013. On-line

and fully operational in fourth quarter 2012, the boiler utilizes renewable carbon-

neutral biomass fuel, reduces fossil fuel use by 75 percent at the mill and cuts

down on electricity purchases while creating an incremental earnings driver for

2013 and beyond.

THE FRANKLIN, VIRGINIA MILL

Realizing an opportunity to repurpose an existing asset and create a low-cost

position in the fluff pulp market, International Paper transformed its Franklin Mill

International Paper / 2012 Annual Report 10/11

BRAZIL—MOGI GUAÇU BOILER

The new boiler at the Mogi Guaçu Mill will generate 210 tons of steam per hour, which

can be converted into enough electricity to supply around 40,000 households. This boiler

complements the steam generators in the pulp manufacturing process, and also supplies electricity

to the mill, where it will provide practically all the energy used in the production process.

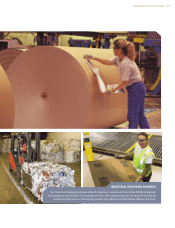

PRINTING

PAPERS

WE ARE THE COMPANY

BEHIND SOME OF THE

BEST-KNOWN AND

HIGHEST-QUALITY

PAPER BRANDS IN

THE WORLD.