Crucial 2011 Annual Report Download - page 7

Download and view the complete annual report

Please find page 7 of the 2011 Crucial annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Manufacturing

Our manufacturing facilities are located in the United States, China, Israel, Italy, Malaysia, Puerto Rico and Singapore. Our Inotera joint

venture also has a wafer fabrication facility in Taiwan. In 2011, we sold our wafer fabrication facility in Japan to Tower Semiconductor Ltd.

("Tower") and entered into a supply agreement for Tower to manufacture products for us in the facility through approximately May 2014. Our

manufacturing facilities generally operate 24 hours per day, 7 days per week. Semiconductor manufacturing is extremely capital intensive,

requiring large investments in sophisticated facilities and equipment. A significant portion of our semiconductor equipment is replaced every three

to five years with increasingly advanced equipment. DRAM, NAND and NOR share common manufacturing processes, enabling us to leverage

our product and process technologies and manufacturing infrastructure across these product lines.

Our process for manufacturing semiconductor products is complex, involving a number of precise steps, including wafer fabrication,

assembly and test. Efficient production of semiconductor products requires utilization of advanced semiconductor manufacturing techniques and

effective deployment of these techniques across multiple facilities. The primary determinants of manufacturing cost are die size, number of mask

layers, number of fabrication steps and number of good die produced on each wafer. Other factors that contribute to manufacturing costs are wafer

size, cost and sophistication of manufacturing equipment, equipment utilization, process complexity, cost of raw materials, labor productivity,

package type and cleanliness of the manufacturing environment. We continuously enhance our production processes, reducing die sizes and

transitioning to higher density products. In 2011, we transitioned the majority of our DRAM production to 42nm line-width process technology

and began transitioning to 30nm line-width process technology. In 2011 most of our NAND Flash memory products were manufactured on our

25nm line-width process technology and we expect to continue transitioning to 20nm line-width process technology in 2012. In 2011, we

manufactured all of our NAND Flash and our high-volume DRAM products on 300mm wafers. We manufactured NOR Flash, some specialty

DRAM and CMOS image sensor products on 200mm wafers. In 2011, the majority of our NOR Flash memory products were manufactured on

our 65nm line-width process technology and we expect to continue transitioning to 45nm line-width technology in 2012.

6

(3)

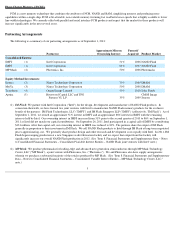

Inotera and MeiYa:

We partner with Nanya Technology Corporation ("Nanya") for the design, development and manufacture of stack

DRAM products, including the joint development of DRAM process technology. In connection therewith, we have partnered with Nanya

in two Taiwan DRAM memory companies, Inotera Memories, Inc. ("Inotera") and MeiYa Technology Corporation ("MeiYa"). We have

a supply agreement with Inotera and Nanya which gives us the right and obligation to purchase 50% of Inotera’s semiconductor memory

capacity subject to specific terms and conditions. Under the formula for this supply agreement, all parties’

manufacturing costs related to

wafers supplied by Inotera, as well as our and Nanya’s revenue for the resale of products from wafers supplied by Inotera, are considered

in determining costs for wafers from Inotera. Inotera accounted for 37% of our DRAM gigabit production in the fourth quarter of 2011.

We also partner with Nanya to jointly develop process technology and designs to manufacture stack DRAM products. In connection with

the partnering agreement, we have also deployed and licensed certain intellectual property related to the manufacture of stack DRAM

products to Nanya and licensed certain intellectual property from Nanya. Under a cost-sharing arrangement effective beginning in April

2010, we generally share DRAM development costs equally with Nanya. In addition, in 2010 we began receiving royalties from Nanya

for sales of stack DRAM products manufactured by or for Nanya with technology developed prior to April 2010. (See "Item 8. Financial

Statements and Supplementary Data – Notes to Consolidated Financial Statements – Equity Method Investments – Inotera and MeiYa

DRAM Joint Ventures with Nanya" note.)

(4) Transform: On December 18, 2009, we acquired a 50% interest in Transform Solar Pty Limited ("Transform"), a subsidiary of Origin

Energy Limited ("Origin") in exchange for nonmonetary assets with a fair value of $65 million, consisting of manufacturing facilities,

equipment, intellectual property and a fully-paid lease to a portion of our Boise, Idaho manufacturing facilities. Transform develops and

manufactures photovoltaic solar panels. (See "Item 8. Financial Statements and Supplementary Data – Notes to Consolidated Financial

Statements – Equity Method Investments – Transform" note.)

(5)

Aptina:

We manufacture CMOS image sensor products for Aptina under a wafer supply agreement. We own 64% of Aptina’s common

stock and none of their preferred stock resulting in a total ownership interest in Aptina of 35%. Our investment in Aptina is accounted

for as an equity method investment, in which we recognize our share of Aptina’s results of operations based on our 64% share of

Aptina’s common stock. (See "Item 8. Financial Statements and Supplementary Data – Notes to Consolidated Financial Statements –

Equity Method Investments – Aptina" note.)