Konica Minolta 1999 Annual Report Download - page 15

Download and view the complete annual report

Please find page 15 of the 1999 Konica Minolta annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

KONICA 11

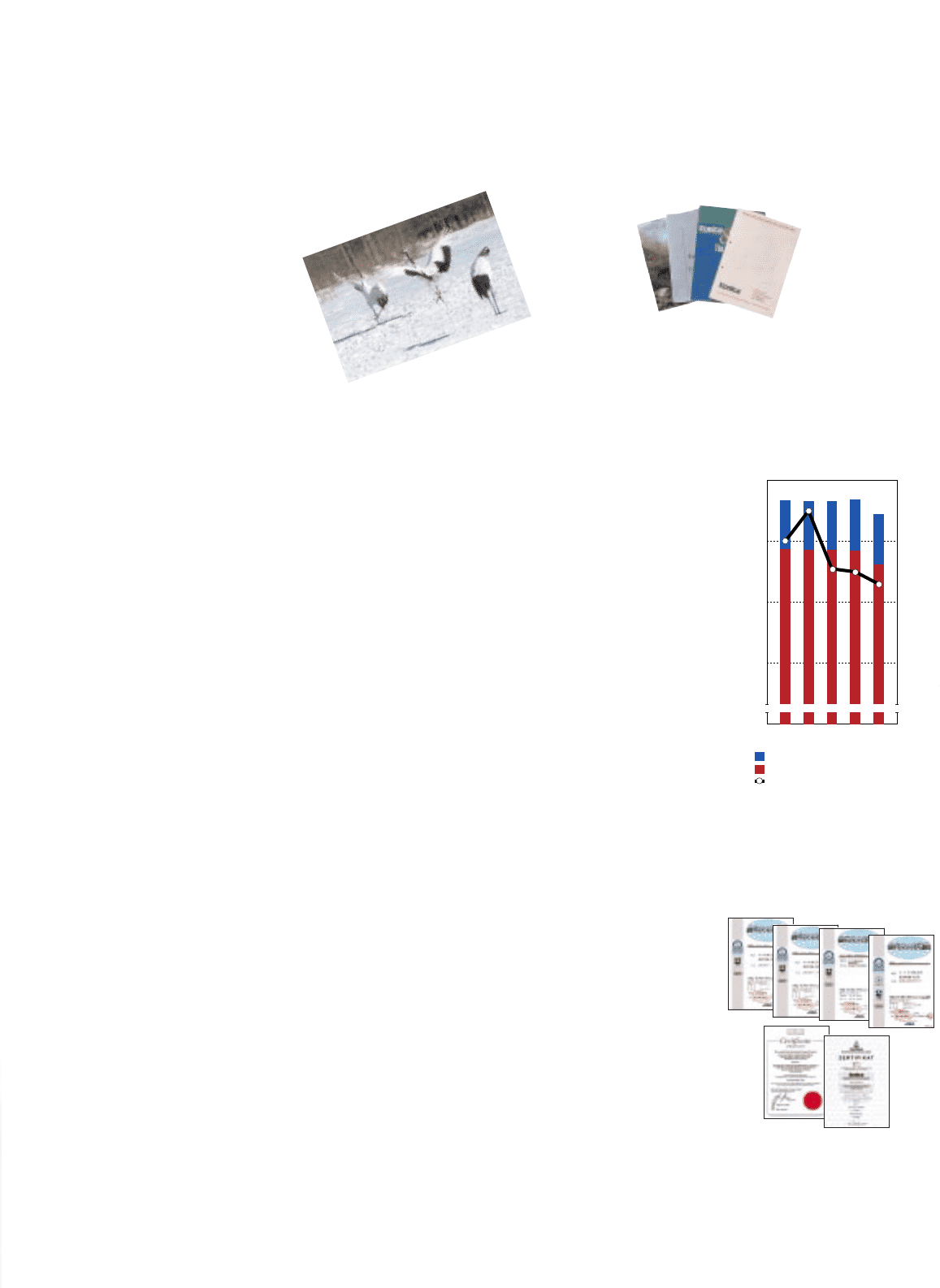

Energy Consumption

0

30,000

60,000

90,000

120,000

0

80

90

100

110

’94 ’95 ’96 ’97 ’98

(%)

Crude oil (kl)

Energy use at all domestic manufacturing subsidiaries

Energy use at all Konica domestic manufacturing facilities

Energy use to sales (1994=100)

...

0101010001010000000000000010101000001010100011111000010101000101011011010101010111010101011101010

Preserving the global environment is a management priority at Konica. In our Konica Environ-

mental Policy, established in 1990, we have expressed our intention to actively implement mea-

sures to reduce the impact of our operations on the environment and help create a cleaner and

healthier planet.

RKonica has established various bodies within its organization to improve its ability to identify

and resolve environmental problems. In Japan, Konica’s Environment and Safety Department is

responsible for planning environmental preservation measures, while in Europe and North America

Environmental Protection centers have been established to promote regional activities based on

our environmental policies. Konica joined the Japan Responsible Care Council upon the organiza-

tion’s foundation in 1995 and established the Konica Responsible Care Committee in the same

year to oversee such activities.

RKonica has set an industry example in creating and maintaining clean and efficient manufacturing

operations. We installed Japan’s first private cogeneration power system at our Hino manufactur-

ing facility in Tokyo, in 1987, and eliminated the use of ozone-depleting substances in cleaning

processes in May 1993, well before the December 1995 deadline set in The Montreal Protocol in

1992. In fiscal 1999, we began full-scale “Green Purchasing” programs, thereby expanding the use

of recycled materials. In addition, our Odawara manufacturing facility received an award from the

Environment Agency in recognition of our ongoing efforts to prevent global warming.

RSince 1993, Konica has conducted environmental assessments on all its products. By focusing

on environmental issues at the R&D stage, these assessments have helped make pioneering advances

in several product categories. For example, in 1994 we introduced the Konica Nice Print System

ECOJET series, the world’s first minilabs to use environmentally sound tablet-form photofinishing

chemicals, thereby reducing effluent and replenisher requirements. In 1997, we established our Life

Cycle Assessment (LCA) Committee, which is conducting LCA programs that provide quantitative

analyses of the environmental impact of products throughout their entire life cycles. We are contin-

uing to develop quantitative standards to gain even more accurate analyses of the environmental

impact of products.

RKonica is continuing to improve environmental management systems throughout its global

network. By the end of fiscal 1999, all four of Konica’s domestic manufacturing sites had obtained

ISO 14001 certification. Overseas, the Company’s U.S.-based photographic paper manufacturer,

Konica Manufacturing U.S.A., Inc., received ISO 14001 certification in fiscal 1999, and all other

manufacturing bases in Konica’s global network are working to receive ISO 14001 certification.

Konica has obtained ISO 14001

certification at all four of its domestic

manufacturing sites.

Konica publishes several booklets

on environmental issues.