Sharp 2009 Annual Report Download - page 17

Download and view the complete annual report

Please find page 17 of the 2009 Sharp annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

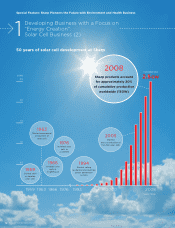

Until now, most of the world’s solar power has come from

crystalline solar cells. Sharp will also develop its produc-

tion framework to accommodate thin-film solar cells, for

which future demand is expected. At Sharp’s Katsuragi

Plant, we boosted annual solar cell production capacity

from 15MW to 160MW in October 2008. In addition, we

plan to begin operations at our new solar cell plant cur-

rently under construction in Sakai City, Osaka Prefecture

by March 2010. The new plant in Sakai will become a

mother plant for building solar cell plants in other coun-

tries as we advance our drive to establish a global produc-

tion framework. Sharp aims to establish a presence across

the entire solar power value chain as a total solutions

provider, active in production of solar cell materials, cells

and modules, as well as in system integration (SI) and the

independent power producer (IPP) business.*

In the past, we have constructed factories in Japan on our

own. Now, we plan to use alliances with local companies

to establish overseas production bases located in the area

where the products will be used. We aim to put in place a

complete value chain in the consumption area, encom-

passing each step from procuring materials through manu-

facturing and sales, a concept that we call local production

for local consumption. This business model enables us to

receive a return for our proprietary technologies and know-

how as technology assistance fees in the form of initial

payments and royalties, and as dividends and other revenues

from joint ventures. This serves to minimize risks involved in

foreign exchange rates and the recovery of capital expendi-

tures. One example is the alliance with Enel SpA, an Italian

power company. Looking ahead, we plan to build a thin-film

solar cell plant in Europe and participate in IPP business

using photovoltaic power generation in this region.

Becoming a Total Solutions Provider in Photovoltaic Power Generation

When comparing solar cells to oil as an energy source, solar cell plants take the place of oil fields.

However, there is one critical difference: while oil fields will eventually be depleted, the world will

never run out of energy from the sun.

* Independent Power Producer (IPP) business: A business that builds and operates its own power generation facilities, and sells the electric power it gener-

ates to power companies.

Becoming a Total Solutions Provider

Production of

materials

Power

generation

businesses

Solar cell/

module

production

System

integration