Porsche 2003 Annual Report Download - page 86

Download and view the complete annual report

Please find page 86 of the 2003 Porsche annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

82

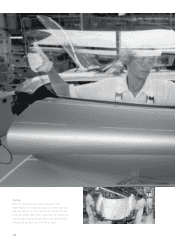

By providing in-depth training on new components, work

operations, and machines, we were able to ensure high stan-

dards of workmanship during and after the changeover. Such

standards are imperative in areas such as the characteristic

decorative stitched seams inside the car. Quality assurance in

the upholstery shop begins with the workers on the sewing

machines, where a computer now monitors the tension and

number of stitches. We also introduced new tools for locating

the seams and custom designed machinery such as a new

door-panel heat sealing machine.

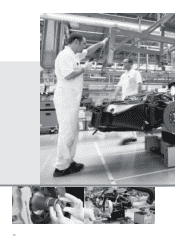

Despite all these technological developments, our employees

remain at the heart of the manufacturing process. New pro-

duction technologies, however effective, are only one side of

the coin and successful manufacturing is only possible when

you have a highly qualified workforce.

Network Management in Demand

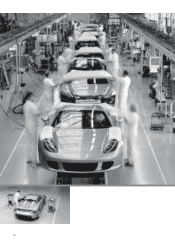

To guarantee first class workmanship on the 911 and smooth-

running logistics right from the outset, we involved our sup-

pliers very closely in our production planning. This has paid

dividends. Thanks to extensive collaboration with our sup-

pliers and our own thorough preparatory work at the plant, we

achieved troublefree, high-quality production (in line with the

growing expectations that our products are obliged to satisfy)

well before series production started.

In addition to collaboration with our suppliers, we devoted

close attention to the production and value-creation alliance

between Zuffenhausen, Leipzig and our Finnish partner’s plant

during the year under review. To ensure a high standard of

professionalism within this alliance, production management

had to coordinate the capacities of external suppliers as well

as those of both Porsche production plants. During the review

year, Porsche made allowance for increased logistical com-

plexity by installing a new organizational business area within

the Production division, with competences extending to all

locations. Within the Porsche production alliance, it uses

optimized processes to control the available capacity at sup-

pliers and production facilities. The aim is to satisfy market

demand at any given time by means of maximum flexibility,

individuality and punctuality.

As part of the network management process, finished-vehicle

transport movements were also examined intensively. It has

proved possible to optimize direct deliveries to our European

sales subsidiaries in a lasting manner by means of a vehicle

monitoring system that tracks both transportation time to the

market and the operating efficiency of the distribution chain

itself.

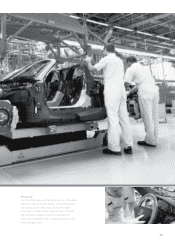

High Levels of Investment

We invested several millions Euros in Zuffenhausen in the run-

up to the production of the new 911. A completely new body-

in-white production line was built alongside the existing one

for the previous model. Much work was required to optimize

the shop floor in order to fit the new machinery and equipment

into the existing space.

We introduced new equipment and techniques in the upholstery

shop for production of the 911’s interior trim. Production

staff also reconfigured the assembly of the bodyshell on to

the running gear and driveline, in order to take advantage of

threaded-connection techniques and supply logistics.

We installed new test rigs to allow us to simulate driving condi-

tions repeatedly free from weather and traffic effects during

series production. We applied for patents on a number of in-

dividual items of equipment that are unique in the automobile

industry. New diagnostic rigs on the lines and new radio

diagnostics for the entire assembly area complete with entirely

new software are responsible for the quantum leap in vehicle

electronics that the new 911 model generation represents.

In addition to the 911 production start-up, Porsche began

production of the new V10 engine for the Carrera GT during

the review year. The production area created for this engine is

fully integrated into the Zuffenhausen plant. Despite its high

complexity and low production volume, the productivity of the

Carrera GT assembly operation benefits greatly from our

existing expertise in the production of longer engine runs.

Production 2003 ⁄ 04

Employees were prepared for

the start of production of the new 911

model by a comprehensive training

program designed to give them

the necessary additional qualifications.