Hamilton Beach 2007 Annual Report Download - page 41

Download and view the complete annual report

Please find page 41 of the 2007 Hamilton Beach annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

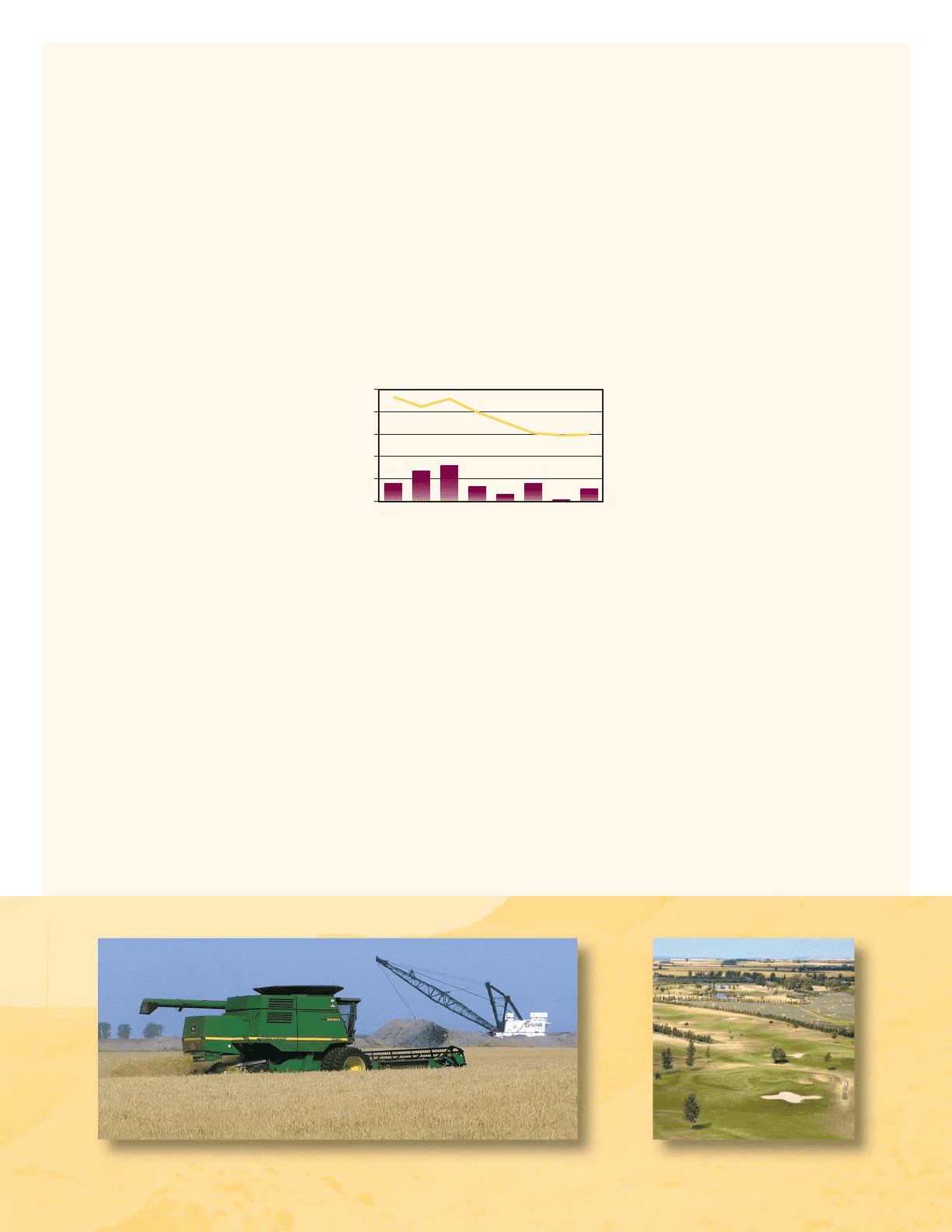

Employee safety. Employee safety is the number-one

priority at NACoal. Nine of the company’s 12 locations

worked the entire 2007 calendar year without incurring a

lost-time accident. NACoal’s incident rate has consistently

been well below the national average for surface coal mines.

NACoal firmly believes its commitment to safety and strong

employee relations improves productivity and employee

retention, thereby reducing costs and enhancing profitability.

Contract structure. Most of NACoal’s mining contracts

minimize exposure to the market price of coal. These

carefully structured coal supply

agreements establish the specific

services NACoal will perform for its

customers and the mechanisms by

which NACoal will be compensated.

These agreements are structured such

that NACoal and its customers share

a common goal of minimizing costs.

By eliminating speculation on the

future price of coal, these contracts

are designed to provide customers

with consistent supplies of low-cost

fuel and allow the company to consistently earn sound

margins for its services.

These contracts also include various cost escalation

mechanisms and may include performance incentives for

NACoal. As inevitable changes occur in mining costs, such

as the costs of diesel fuel, equipment spare parts or tires,

contracts are designed to adjust to those changes so NACoal

neither profits excessively from, nor is unfairly burdened

by, changes in these operational expenses. In the event a

situation arises in which a contract is not properly capturing

cost changes, NACoal works closely with the customer to

resolve the issue.

Lignite mining operations. Production and performance

at most NACoal mines in 2007 was comparable to 2006, with

the exception of two mines where special circumstances led

to lower volumes or higher costs.

NACoal had an outstanding

year at Mississippi Lignite Mining

Company (“MLMC”) as mining

efficiency and productivity rates

improved. However, the company

delivered fewer tons of lignite coal

in 2007 compared with 2006 due

to extended, unplanned outages at

the customer’s power plant. Only

moderate increases in lignite

deliveries are anticipated in 2008

due to another planned power plant

outage. In addition, higher costs are expected as a result

of lower production levels. Increased deliveries are expected

in 2009 and beyond. MLMC has not yet achieved positive

EVI, but with the expected increase in deliveries going

forward, MLMC should attain that goal in the 2009 to

2010 timeframe.

[37]

Left to right: Wheat fields, located on reclaimed land, are harvested at The Falkirk Mining Company in North Dakota. North American Coal returns mined land to its

original or an improved condition. This golf course in North Dakota sits on land previously mined by The Falkirk Mining Company.

Safety Record

(Lost-Time Accident ”LTA” Rate*)

■ LTA North American Coal Average

■ LTA National Average for Surface Coal Mines

00 02 0301 04 05 06 07

0

1.0

0.5

2.0

2.5

1.5

2.33 2.11

2.29 1.99

1.75

1.52 1.47 1.49

0.39 0.67 0.79

0.33

0.16

0.39

0.00

0.28

J

JJ

J

J

JJJ

Incident Rate

*Lower LTA statistics indicate a better safety record as measured

by lost-time accidents in relation to total hours worked.