Hamilton Beach 2007 Annual Report Download - page 22

Download and view the complete annual report

Please find page 22 of the 2007 Hamilton Beach annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

experience and success in building strong, lasting customer and

dealer partnerships should help the company accomplish this

strategy. Also supporting this strategy is NMHG’s strong global

relationship with GE Capital, which, along with other local

financing companies, helps provide and manage a significant

portfolio of loans and leases to lift truck customers, dealers

and NMHG. Several other programs supporting this service

strategy include:

National and global accounts. NMHG has industry-

leading fleet management and national account organizations

in North America and is developing a stronger national

account program in Europe, while continuing to enhance its

global account capabilities. NMHG’s goal is to offer superior

value and services to large customers that have centralized

purchasing but geographically dispersed operations. Benefits

from this program to generate growth will be gradual, but

increasing over the long term.

Dealer structure program. The company continues to

strengthen its worldwide network of strong, professionally

managed, well-capitalized independent dealers as part of its

Anchor Dealer efforts. NMHG’s experience is that these

exclusive Hyster® and Yale® Anchor Dealers can attain higher

market shares, attract higher-quality employees and offer

higher-value services to their customers. In addition, dealer

excellence enhancement efforts are designed to drive improve-

ment at all Hyster® and Yale® dealers, providing dealers with

best practices and performance assessment tools in the areas of

operational and financial management, lift truck and parts

sales, service, rental and fleet management. NMHG also offers

customized consulting assistance to help dealers implement

these programs to improve sales and profitability. In addition, a

number of special initiatives already under way, including order

and contact management systems, a training knowledge center

and customer and dealer satisfaction programs, are expected to

enhance the strong reputations of Hyster® and Yale® dealers.

Benefits from these growth programs are expected to be

realized at NMHG and its dealers over the long term.

Aftermarket parts. NMHG maintains an important

strategic alliance with a leading aftermarket parts provider

located in the Americas, Europe and Asia-Pacific. This alliance

has enhanced Hyster® and Yale® dealers’ offerings of competitive

lift truck parts as part of an effort to increase NMHG’s share of

its customers’ parts and service business. NMHG also continues

to make significant investments in training dealer technicians

in lift truck diagnostics, maintenance and repair procedures to

assure highest-quality customer service. Improvements are

being realized and are expected to increase gradually as a result

of this growth program.

NMHG Retail improvements. NMHG Retail consists of

Yale® in the United Kingdom, Hyster® in Singapore and

Hyster® and Yale® in Australia. During 2007, NMHG sold its

Hyster® dealership that covered part of France and continued

to streamline operations at its Yale® dealership in the United

Kingdom. In its Australian retail operations in 2007, NMHG

implemented an important business improvement program.

The company’s lift truck rental business, previously operating

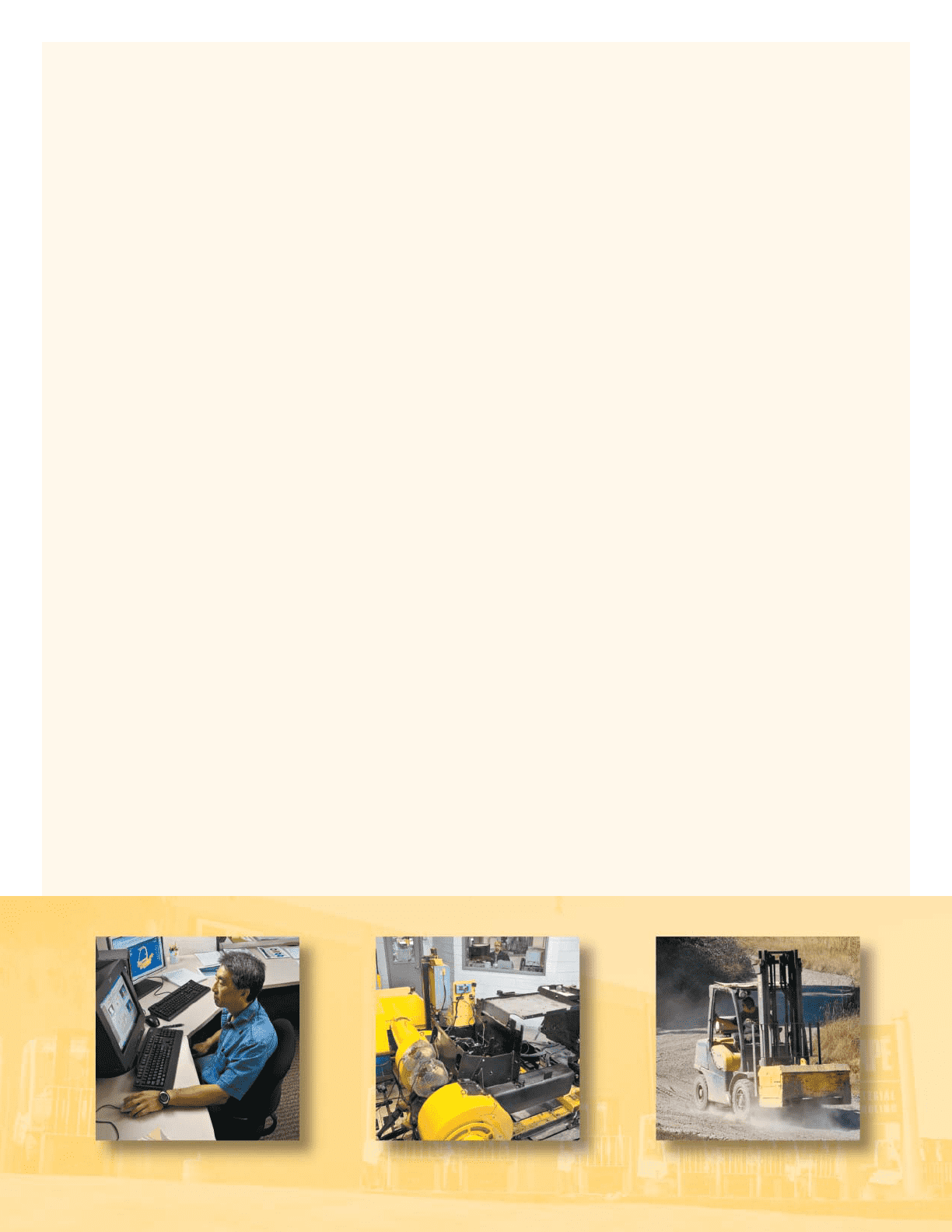

Below left to right: Hyster® and Yale® lift trucks are designed to withstand extreme conditions. Designs are reviewed and rigorously tested at NMHG’s Counterbalanced

Design Center in Portland, Oregon. An engineer does test simulations on a computer program to ensure lift truck specifications are set to withstand various conditions. The

Mustang Dynamometer is used to validate drive axles months or years ahead of truck availability by using fixtures or mule truck chassis in an accelerated testing environment.

A lift truck is tested for durability on a dusty, uneven gravel road.

[18]