Whirlpool 2004 Annual Report Download - page 26

Download and view the complete annual report

Please find page 26 of the 2004 Whirlpool annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

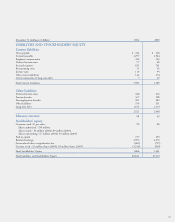

Discontinued Operations

The Company wrote off its investment in leveraged aircraft

leases during the fourth quarter of 2002 as a result of the United

Airlines bankruptcy filing in December 2002. The write-off

resulted in a non-cash charge to discontinued operations of

approximately $68 million, or $43 million after tax. These lever-

aged lease assets were part of the Company's previously discon-

tinued finance company, Whirlpool Financial Corporation.

Although most of its assets have been divested, Whirlpool

Financial Corporation remains a legal entity with assets consist-

ing primarily of a leveraged lease portfolio. As of December 31,

2004 and 2003, the portfolio totaled $15 million and $42 mil-

lion, respectively, net of related reserves. The Company contin-

ues to monitor its arrangements with the lessees and the value of

the underlying assets.

Cumulative Effect of Change in Accounting Principle

The Company adopted Statement of Financial Accounting

Standards (“SFAS”) No. 142, “Goodwill and Other Intangible

Assets,” on January 1, 2002. As a result of this adoption, the

Company recorded a non-cash, after-tax charge of $613 million

in 2002.

Forward-Looking Perspective

During 2004, the Company incurred approximately $300 mil-

lion of higher material and oil-related costs. The Company

expects higher material costs, primarily within North and Latin

America, of $500 to $550 million during 2005, primarily due to

higher prices for steel and resins. To address this challenging

environment, the Company has implemented global price

increases of approximately 5-to-10%, effective January 2005, in

most key markets around the world. The Company has also ini-

tiated actions to drive record levels of controllable productivity,

leverage its global operating platform, reduce non-product

related spending and accelerate the rate of new product innova-

tion to the market. The full effect of these cost increases will be

reflected in the Company's cost structure from the start of 2005,

while benefits of both price increases and productivity improve-

ments will build throughout the year.

North America and Europe, the Company's two largest segments,

expect 2005 industry growth of approximately 2% and 1%,

respectively. The Company's efforts in these two regions during

2005 will be to execute previously announced price increases,

drive record levels of controllable productivity, and expand its

market share through leveraging its strong brand portfolio,

expanding key market leadership and introducing continuous,

relevant, branded innovations to the market.

Macroeconomic conditions in Latin America are expected to

remain positive during 2005, and the Company expects industry

shipments to increase 4-to-5%. Price increases implemented

throughout 2004, and additional increases enacted for 2005, are

expected to offset significant material cost increases.

Manufacturing and supply chain productivity is anticipated to

contribute to improved operating profit margin performance and

exports to the Company's global operations are expected to

increase.

Asia results will benefit from new product introductions,

improved product mix and favorable comparisons to last year's

results that reflected the Company’s inventory trade-reduction

strategy in India. The Company will continue to expand its

China procurement and technology base to support its global

operations, expand domestic sales within China and India, and

increase global exports of components and finished product.

Cash Flows

Whirlpool's main source of cash flow is from operating activities.

The Company's 2004 cash provided by operating activities bene-

fited from lower after-tax pension contributions of approxi-

mately $62 million and lower restructuring spending of

approximately $56 million. Cash flow was negatively impacted

by higher working capital requirements of about $70 million,

driven largely by material cost increases and higher inventory

levels to support higher volumes and increased trans-regional

shipments. The Company's 2003 cash provided by operating

activities benefited from higher earnings, primarily within the

European and North American business segments, as well as

continued improvement in working capital management. Cash

flow was negatively impacted by a voluntary, after-tax pension

contribution to the Company's U.S. pension plans of $97 mil-

lion. In comparison, after-tax U.S. pension contributions made

during 2002 were $5 million. The 2003 results were also nega-

tively impacted by restructuring spending, primarily related to

22