Pentax 2010 Annual Report Download - page 21

Download and view the complete annual report

Please find page 21 of the 2010 Pentax annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

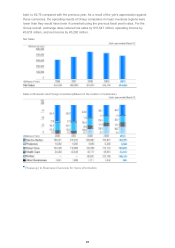

Intraocular Lenses (IOL)

IOL Global Market size expectation

(company estimate)

Market share in Japan

(company estimate)

iSert™ pre-loaded IOL delivery

system

Business Overview

Health Care Division

Fiscal 2010 Business Overview and Results

The global market for intraocular lenses (IOLs) used in cataract surgery is

expanding as the number of cataract surgery patients increases alongside aging

demographics and increased economic development in emerging economies. The

majority of intraocular lenses used to replace the natural lens in cataract patients

are currently standard, spherical monofocal IOLs. However, in many developed

nations around the world, patients' increasing demand for improved Quality of Life

is creating new markets for aspherical, multifocal, toric and accommodating IOLs.

Currently, the worldwide market is $2.1 billion and is projected to grow to $3.1

billion in the next five years.

Hoya's hydrophobic IOLs, using a precision lathe-cut manufacturing method1,

which results in superior optical quality. Hoya IOLs are available in a novel

pre-loaded insertion system that provides safety, efficiency and predictability for

surgical outcomes. The lenses are currently available in Japan, Europe, Asia and

the United States. In Japan, the Company has already captured 30% of the total

market. During fiscal 2010, performance was driven by sales growth in Japan,

China, Italy, and the United States, allowing the division to achieve year-on-year

growth in revenues.

During the fiscal year under review Hoya began selling the iMics1™ series of

hydrophobic IOLs, which enable surgeons to insert the lens through an incision

size as small as 1.8mm, resulting in superior patient outcomes. Japan sales

commenced in June 2009, and sales were launched in European countries in

January 2010, with the series receiving strong reception in all markets. In August

2009, the Company launched iSert™ pre-loaded IOL delivery system in the United

States, the only small incision system of its kind currently available in the United

States, the world's largest market for IOLs. The pre-loaded system has earned a

positive response from ophthalmological associations and ophthalmologists for

making safer, more efficient cataract surgery possible. Hoya launched iSert™ in

Korea in January 2010, and plans to follow up with launches in India. Both

iMics1™ and iSert™ contribute to ophthalmological medicine by providing not only

high-quality, precision lenses, manufactured using Hoya's outstanding proprietary

optical technologies and materials, but also revolutionary insertion devices that

make surgery more predictable for both patients and doctors.

In addition to developing improved products, Hoya also offers hospitals and clinics

unique supply chain systems to support their business operations. One example of

such support is SAMI™ (Smart Automated Micro-tag Inventory), an inventory

management system that the Company has launched in the United States. SAMI™ uses RFID tags on product packages

to reduce doctors' administrative load, while automating inventory management and ordering processes and increasing

efficiencies.

1 Lathe cutting is a manufacturing process which fabricates lenses precisely one by one from button shaped materials using computer

controlled machine. In HOYA, a cutting-edge line combined with pad polishing and tumble polishing processes is used to achieve sharp

edge and smooth optic surface.

/

20